A high-efficiency, low-roll-off phosphorescent organic light-emitting diode

A technology of light-emitting diodes and organic light-emitting layers, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of increasing phosphorescent OLED heterojunction interface, complex preparation process, high driving voltage, etc., and achieve balanced electron and hole distribution. , the effect of wide carrier recombination region and high device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] During the preparation process of the device, the evaporation rate of the material and the thickness of the organic and inorganic film layers are monitored and controlled by a quartz crystal frequency meter connected outside the vacuum chamber. Among them, organic materials, MoO 3 The evaporation rates of LiF, LiF, and Al are about 1Å / s, 0.3Å / s, 0.1Å / s, and 3Å / s, respectively. The overlapping part of the ITO glass and the aluminum cathode is used as the effective light-emitting layer of the device, and the effective light-emitting area is 3mm×3mm.

[0059] The performance test method of the OLED device involved in the embodiment of the present invention is as follows.

[0060] Take out the prepared white OLED device from the vacuum cavity, and measure the current density, luminance, current efficiency and power efficiency of the device by using the computer integrated control ST-900M photometer and Keithley 2400 digital source meter; use computer integrated control Th...

Embodiment 1

[0064] A green phosphorescent OLED device was prepared according to the above specific embodiments. The specific device structure is ITO / MoO 3 (3nm) / TAPC (40 nm) / TCTA: 7wt%Ir(ppy) 3 (5 nm) / TCTA: Bepp 2 (1:1): 7wt%Ir(ppy) 3 (10 nm) / Bepp 2 : 7wt%Ir(ppy) 3 (5 nm) / TmPyPB (50 nm) / LiF (1 nm) / Al (100 nm).

[0065] In the above green phosphorescent OLED device, 3 nm thick MoO 3 Thin layer is HIL, 40nm thick TAPC layer is HTL, 5nm thick TCTA: 7wt%Ir(ppy) 3 Layer as first EML, 10nm thick TCTA: Bepp 2 (1:1): 7wt%Ir(ppy) 3 The layer is the second EML, 5nm thick Bepp 2 : 7wt%Ir(ppy) 3 The layer is the third EML, the 50nm thick TmPyPB layer is the ETL, the 1nm thick LiF is the EIL, the ITO is the anode, and the 100nm thick Al film is the cathode.

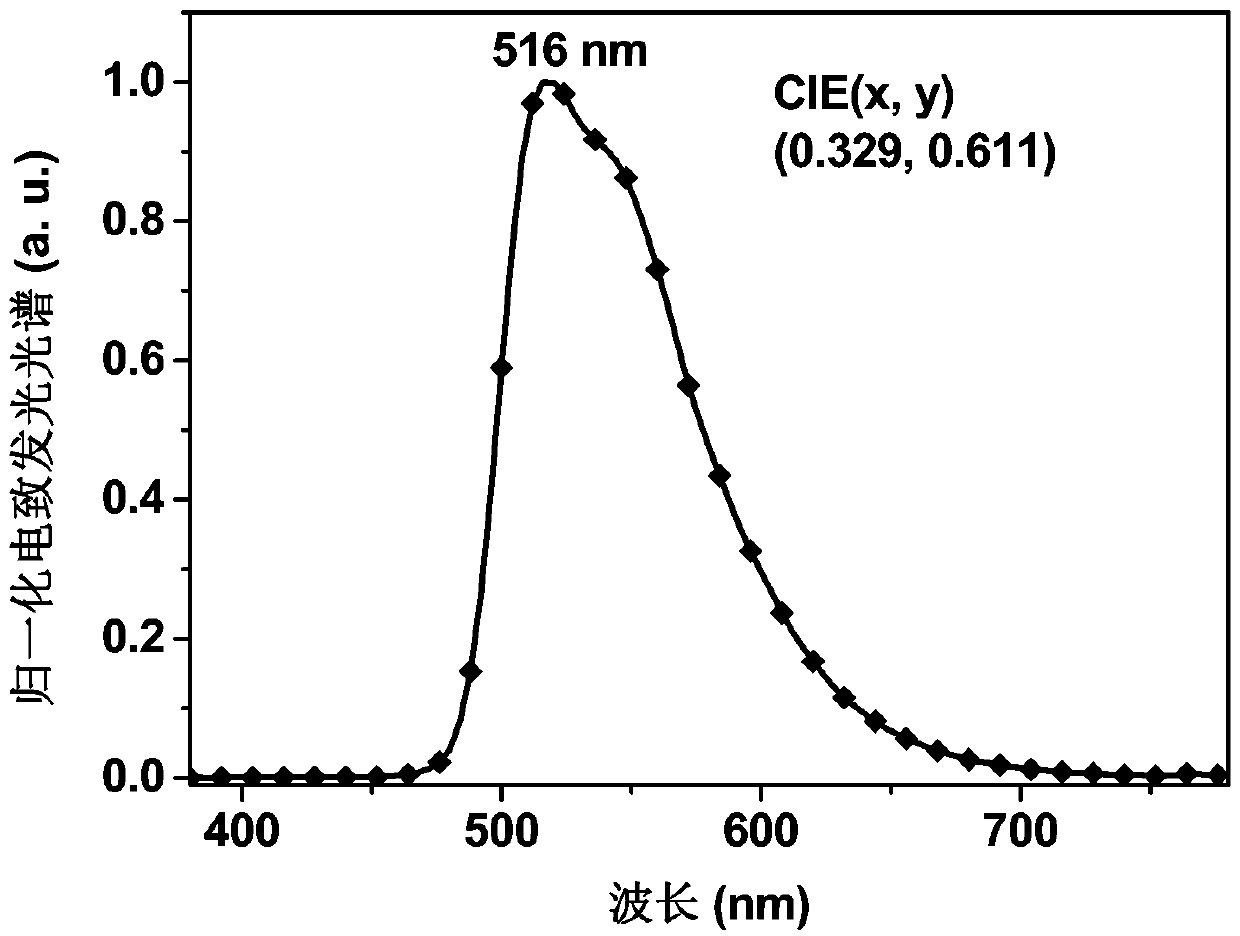

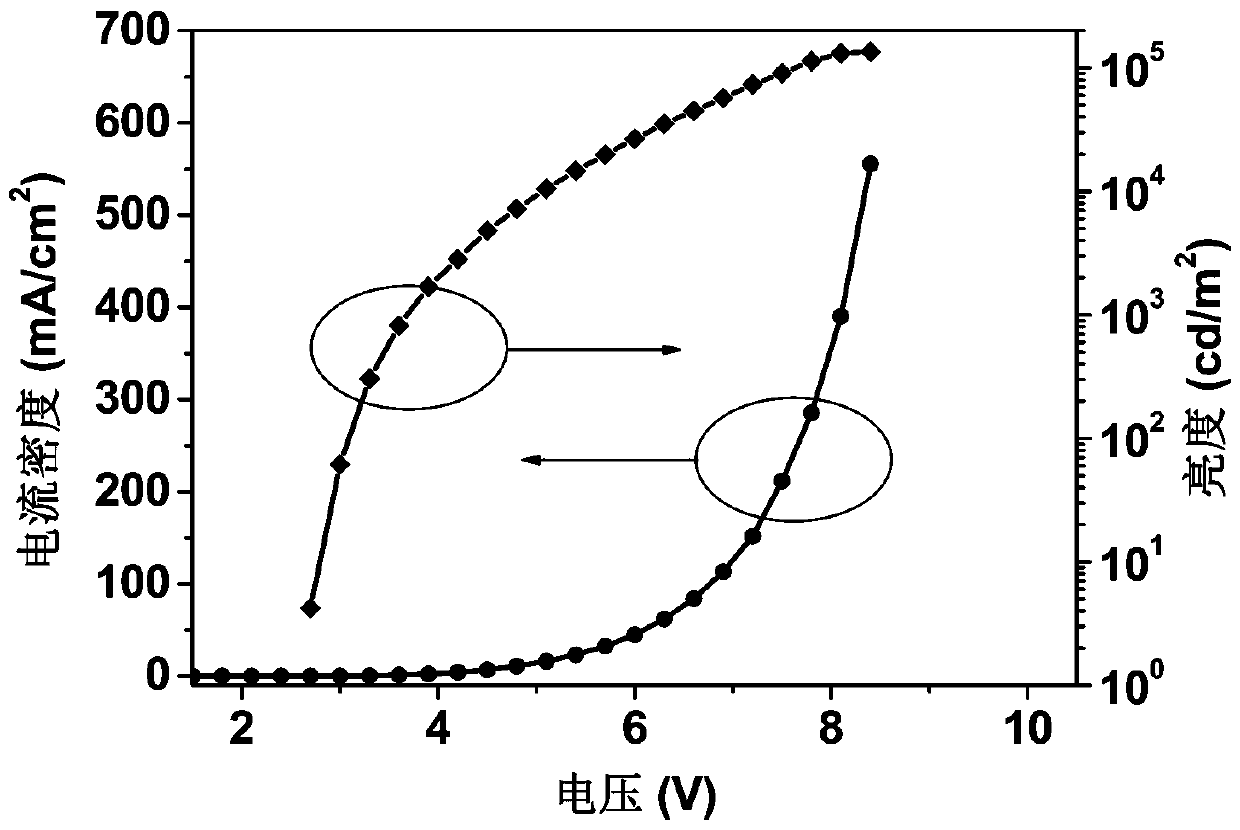

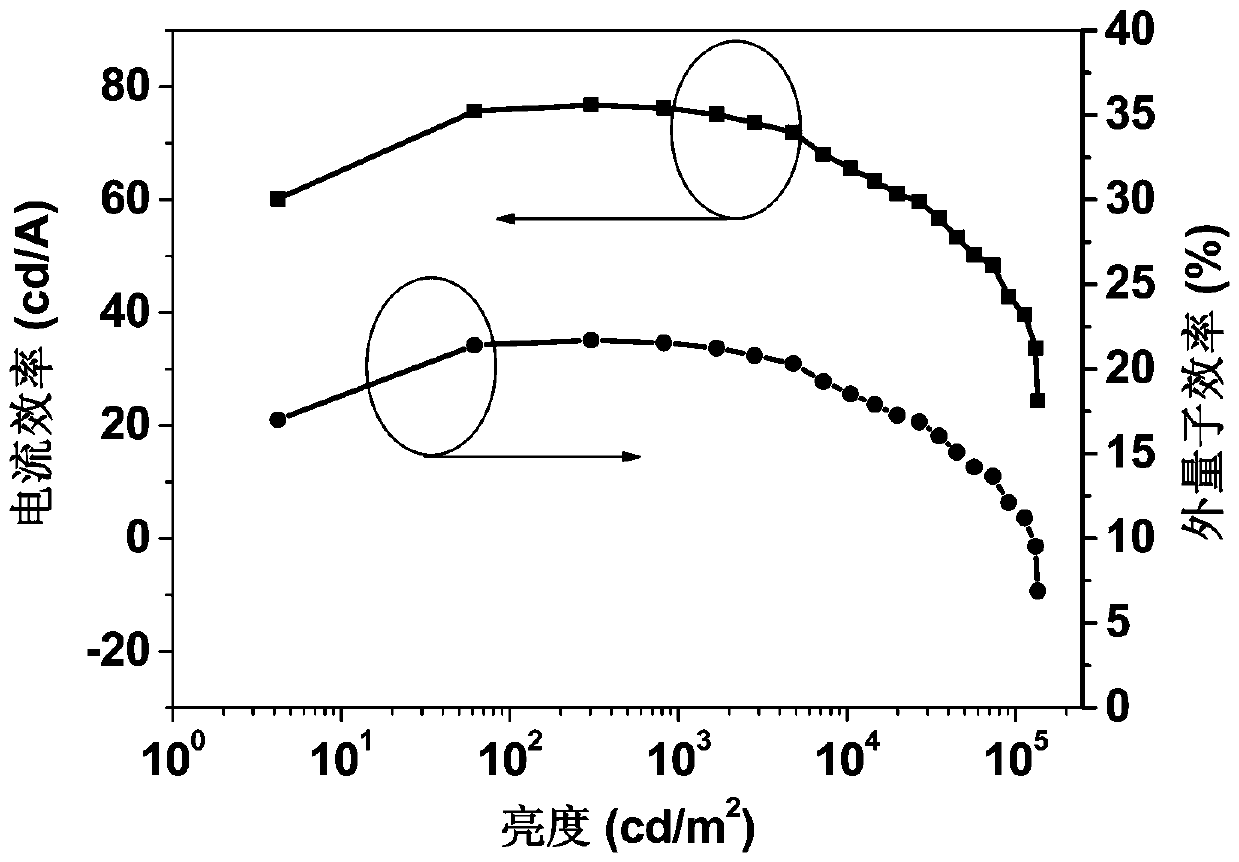

[0066] figure 1 The electroluminescence spectrum of the device of this example at a voltage of 5V is given. It can be seen that the device emits very good green light, and there is only one emission peak in the electroluminesce...

Embodiment 2

[0070] In order to further prove the feasibility of the high-efficiency, low-roll-off phosphorescent organic light-emitting diode structure proposed by the present invention, this example keeps the device structure, functional materials and thin layer thickness of Example 1 unchanged, and uses the yellow phosphorescent material Ir(bT) 2 (acac) instead of green phosphorescent material Ir(ppy) 3 Doped in the host material, the yellow phosphorescent OLED device is prepared. The specific device structure is ITO / MoO 3 (3 nm) / TAPC (40 nm) / TCTA: 6wt% Ir(bT) 2 (acac) (5 nm) / TCTA:Bepp 2 (1:1): 6wt% Ir(bT) 2 (acac) (10 nm) / Bepp 2 : 6wt% Ir(bT) 2 (acac) (5 nm) / TmPyPB (50 nm) / LiF (1 nm) / Al (100 nm).

[0071] 5nm thick TCTA: 6wt%Ir(bT) in the above yellow phosphorescent OLED device 2 (acac) layer as first EML, 10nm thick TCTA: Bepp 2 (1:1): 6wt%Ir(bT) 2 The (acac) layer is the second EML, 5nm thick Bepp 2 : 6wt%Ir(bT) 2 The (acac) layer is the third EML.

[0072] Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com