Fresh yellow ceramic ink-jet infiltrating ink

A ceramic inkjet and yellow technology, applied in ink, household utensils, applications, etc., can solve the problems of not being bright enough, limited colors, narrow color gamut, etc., and achieve rich color gamut, good inkjet printing performance, and stable color development Effect

Inactive Publication Date: 2018-07-13

FOSHAN UNIVERSITY

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the color bodies used in bleeding ink are organometallic salts. These organic metal salts are easy to chemically react with the relevant components in the polished tile fabric, and it is difficult to emit bright colors at high temperatures. This is the technology in the application process of bleeding ink. difficulty

Although Chinese patent 201510429407.0 discloses a nano-silicon oxide material, which can wrap the organic metal salt in situ during high-temperature firing, so as to ensure that the metal salt will not react with other substances and achieve stable color development of the ink, but currently The developed colors are still limited, mainly including blue, brown, yellow and black inks, so it is necessary to develop some new primary color ceramic inkjet bleeding inks to enrich the color gamut of inkjet polished tiles

[0004] Chinese patent 201510141827.9 discloses the use of organic titanium salt and chromium salt to prepare yellow bleeding ink, but the color of the ink is a bit dark, orange, not bright enough, and the color gamut is narrow, and some intermediate colors or mixed colors need more vivid colors yellow to show

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

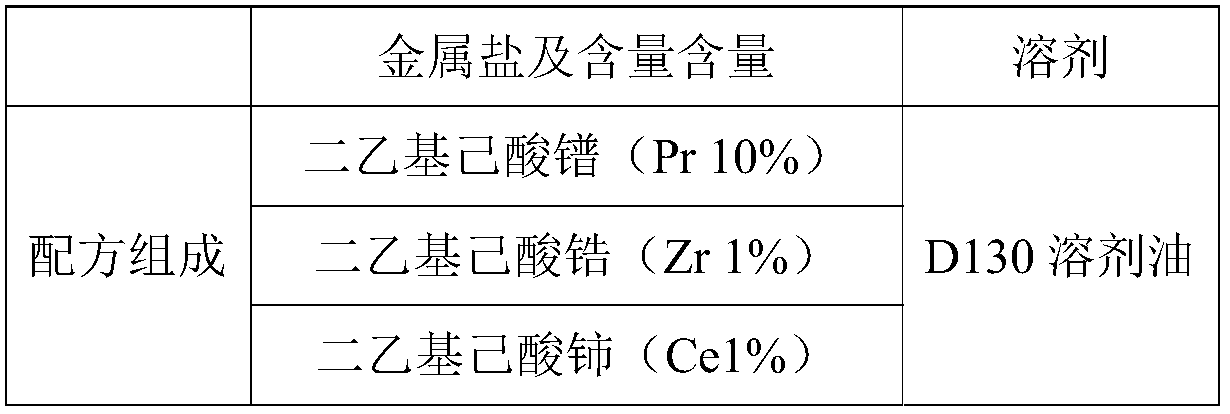

Embodiment 1

[0020]

[0021] The viscosity of bleeding ink is 20mPa s and the surface tension is 25mN / m.

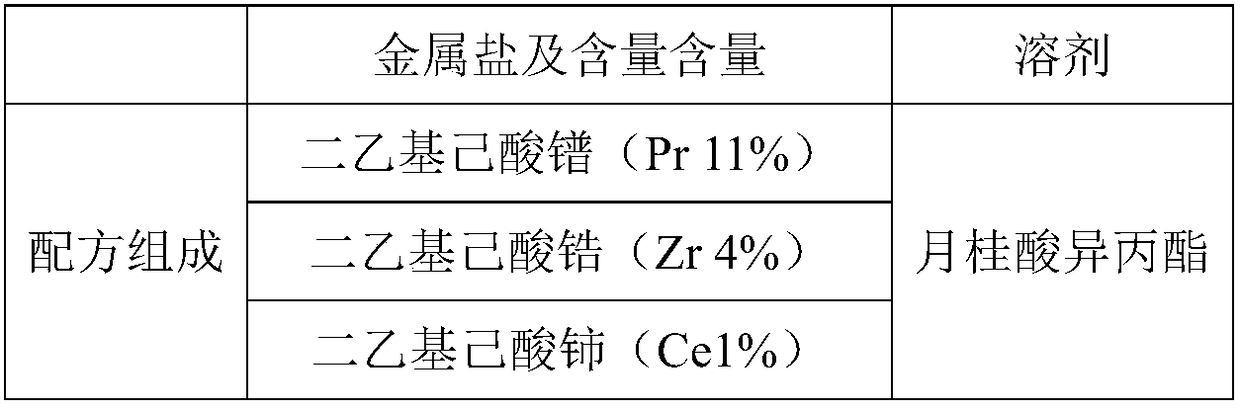

Embodiment 2

[0023]

[0024] The viscosity of bleeding ink is 25mPa s and the surface tension is 26.5mN / m.

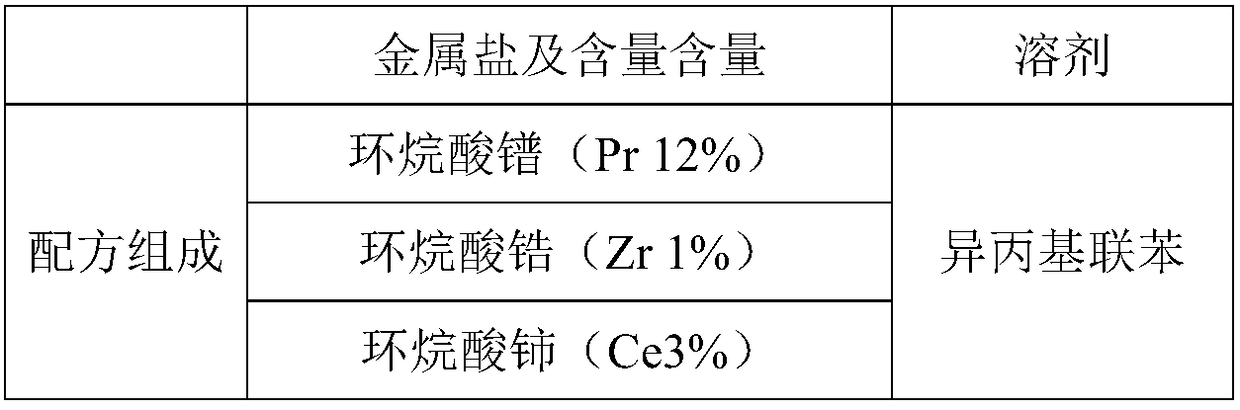

Embodiment 3

[0026]

[0027] The viscosity of bleeding ink is 30mPa s and the surface tension is 30.0mN / m.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a fresh yellow ceramic ink-jet infiltrating ink which is composed of a color development organic metal salt and a solvent, and the color development organic metal salt is dissolved in the solvent and can be converted into a fresh yellow metal oxide at a high temperature. The organic metal salt is a mixed salt of organic praseodymium, organic zirconium and organic cerium, and in terms of the metal ions, the content of praseodymium is 10-12%, the content of zirconium is 1-4%, and the content of cerium is 1-3%. The ink disclosed by the invention has a fresh yellow decorative effect and can enrich the color range of the ceramic infiltrating ink, so that the color of the ink-jet polished tile is richer and brighter in color.

Description

Technical field [0001] The invention relates to the technical field of ceramic inkjet printing, in particular to a bright yellow ceramic inkjet bleeding ink. Background technique [0002] Polished tiles have a wear resistance that is unmatched by fully polished glazed tiles. However, due to the polishing process of polished tiles, inkjet printing technology cannot be applied, resulting in lack of pattern texture and high development costs. With the advent of bleeding inks and related techniques, polished tiles can also be covered with natural coats such as wood grain and stone, just like fully polished glazed tiles. [0003] Ceramic bleed ink using soluble metal salt as the color body can penetrate into the interior of the tile and can be used for the decoration of polished tiles. The inkjet polished tiles produced have the three-dimensional texture of stone, the hardness of polished tiles and the naturalness of polished tiles. Color texture has become an epoch-making ceramic tile...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D11/32

CPCC09D11/32

Inventor 陈东初叶秀芳常萌蕾魏红阳

Owner FOSHAN UNIVERSITY

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com