Automobile graphene flame retardant restraint damping fin and preparation method thereof

A constrained damping, graphene technology, applied in chemical instruments and methods, vehicle parts, transportation and packaging, etc., can solve the problems of large impact on the mechanical properties of the matrix, irritating gas, secondary hazards, etc., to achieve good synergy Flame retardant properties, smoke density reduction, fast vulcanization effect

Active Publication Date: 2018-07-13

CHANGZHOU UNIV

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the research, it was found that the materials made of the halogen-containing flame retardant system will produce a large amount of smoke and toxic corrosive hydrogen halide gas when heated, which will cause secondary hazards; when the amount of the inorganic flame retardant system is nearly 100 parts, the matrix can To achieve a better flame retardant effect, a large amount of flame retardant has a greater impact on the mechanical properties of the matrix; phosphorus and nitrogen flame retardant systems need to be compounded to achieve a better flame retardant effect, and in the process of burning Irritant gas will be produced in the air, the above phenomena restrict the use of butyl rubber constrained damping materials in some airtight occasions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

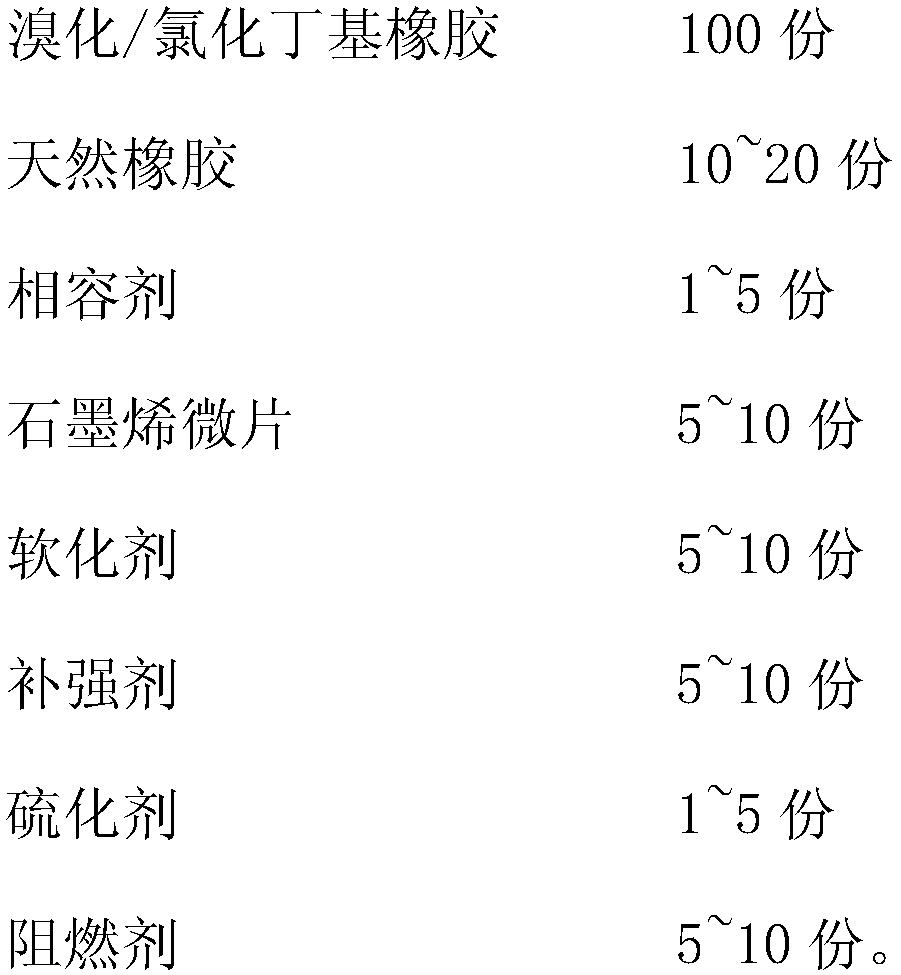

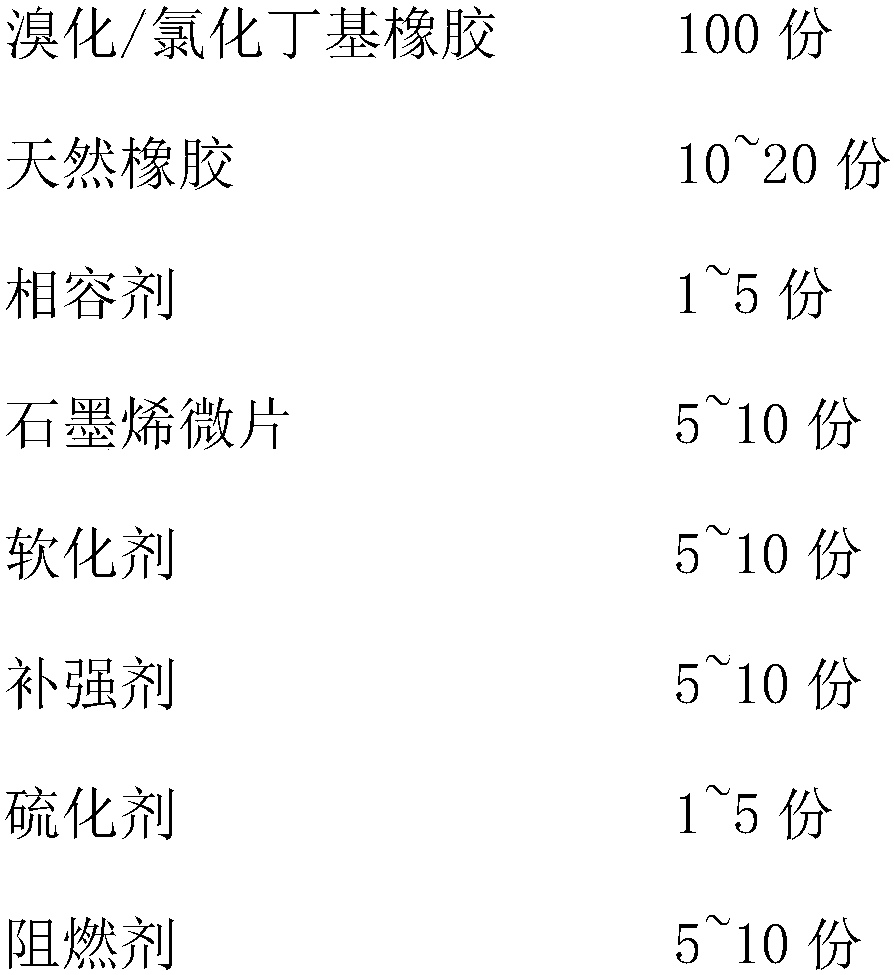

[0030] According to the ratio in Table 1, brominated / chlorinated butyl rubber, graphene microflakes, softener, reinforcing agent, and vulcanizing agent were blended and kneaded, and after mixing evenly, they were extruded into sheets by a single-screw extruder , combined with the constrained layer and the substrate at the die head to obtain a graphene flame-retardant constrained damping sheet for vehicles.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

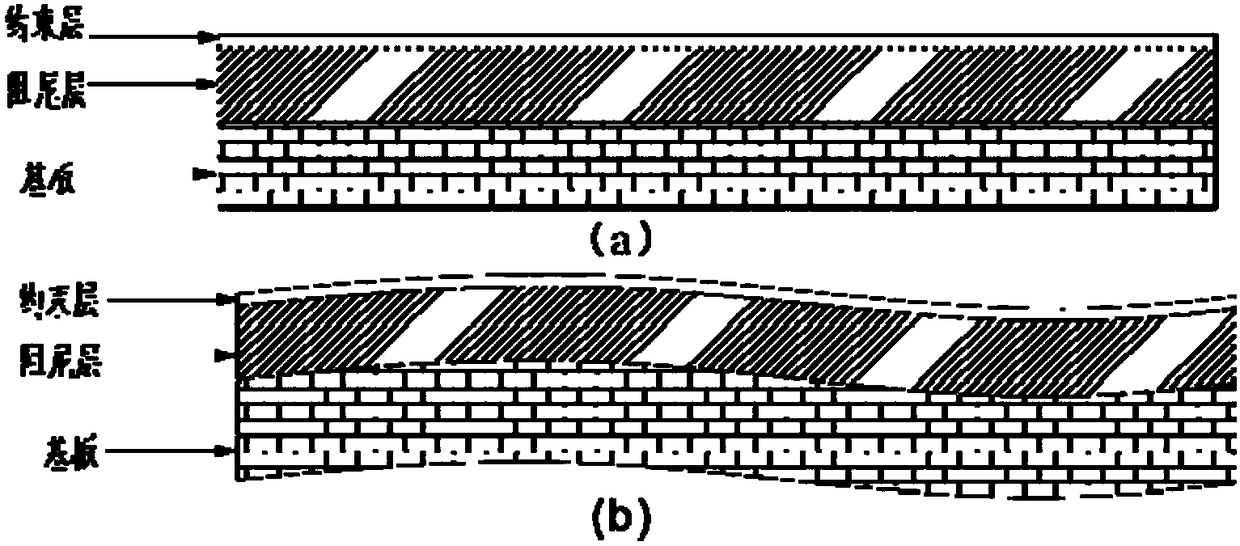

The invention relates to preparation of restraint damping fins, and mainly relates to an automobile graphene flame retardant restraint damping fin and a preparation method thereof. Brominated / chlorinated butyl rubber is used as a damping matrix material; by use of the intrinsic flame retardant property of a graphene microchip and extremely high synergetic flame retardant property of an added phosphorus based flame retardant, the brominated / chlorinated butyl rubber, the graphene microchip, a softening agent, a reinforcer and a vulcanizing agent are blended and mixed; after the materials are uniformly mixed, the mixture is extruded by a single-screw extruder to form a sheet; the sheet is combined with a restraint layer and a base plate at a die head, so that the automobile graphene flame retardant restraint damping fin is obtained.

Description

technical field [0001] The invention relates to the preparation of a constrained damping sheet, and mainly relates to a graphene flame-retardant constrained damping sheet for vehicles and a preparation method thereof. Background technique [0002] With the densification of the urban rail transit network, the impact of railway vibration on nearby residents, ancient buildings, and precision instruments has attracted increasing attention. In 2017, a public opinion test by the German Federal Environmental Agency showed that in daily life, about 40% of residents are disturbed by road traffic noise, 37% of residents are disturbed by aviation traffic noise, and 23% of residents are disturbed by railway noise. Track vibration isolation pad is a rubber vibration isolation pad used in high-speed rail and subway tracks and viaducts. The damping layer of the vibration isolation pad has a strong damping ability and can attenuate high-frequency vibration when trains pass at high speed. T...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/28C08L7/00C08K13/04C08K7/00C08K3/04C08K3/22C08K3/06C08K5/523B32B15/06B32B15/18B32B15/20B32B25/20

CPCB32B15/06B32B15/18B32B15/20B32B25/20B32B2605/10C08K2003/2296C08L23/283C08L2201/02C08L2205/03C08L7/00C08K13/04C08K7/00C08K3/04C08K3/22C08K3/06C08K5/523

Inventor 陶宇吴嘉欣甘国民伍人赞孙妮郭东亚刘威

Owner CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com