A thermally excited delayed fluorescent guest material and its preparation and application

A technology of delayed fluorescence and object materials, which is applied in the direction of luminescent materials, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., and can solve the problems of strict three-dimensional structure requirements, and few types of thermally excited delayed fluorescence object materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] According to the above-mentioned preparation method, the preparation method comprises the following steps:

[0070] (1) Combine carbazole, 3,6-di-tert-butylcarbazole, 9,9-dimethylacridine, phenoxazine, and phenothiazine with fluoro-o-dibromobenzene, cuprous iodide, Put the weak base in a round-bottomed flask, add the solvent dimethyl sulfoxide to mix, stir at 150°C for 12 hours under the protection of argon, stop the heating reaction and lower it to room temperature, wash the reaction mixture with water three to four times, and then use two Extracted with methyl chloride, the organic layer was dried with anhydrous sodium sulfate, and the solvent was removed with a rotary evaporator, and the obtained concentrate was purified by column chromatography to obtain intermediate I;

[0071] (2) Dissolve the intermediate I in tetrahydrofuran, place it in a three-necked round-bottomed flask that has been baked to remove water, cool it to -120°C with a mixture of liquid nitrogen a...

Embodiment 1

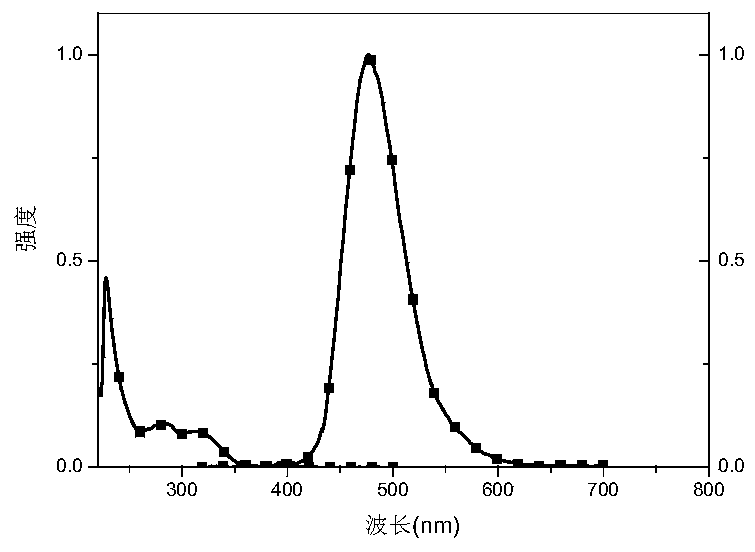

[0097] Example 1 Preparation of Thermally Excited Delayed Fluorescence Guest Materials 1a-1e

[0098] (1) Mix 2mmol carbazole, 3,6-di-tert-butylcarbazole, 9,9-dimethylacridine, phenoxazine, and phenothiazine with 1mmol 1,2-dibromo-4,5- Difluorobenzene, 0.02mmol cuprous iodide, and 1mmol potassium carbonate were placed in a 50ml three-necked round-bottomed flask that had been baked to remove water, and the solvent dimethyl sulfoxide was added, and stirred at 150°C for 12h under the protection of argon, and then stopped Heat the reaction down to room temperature, wash the reaction mixture three to four times with water, then extract with dichloromethane, and wash the organic layer with anhydrous Na 2 SO 4 Drying, rotary concentration with a rotary evaporator to remove the solvent, the obtained concentrate was purified by column chromatography, and the solvent used for column chromatography purification was a mixed solvent of petroleum ether and dichloromethane with a volume r...

Embodiment 2

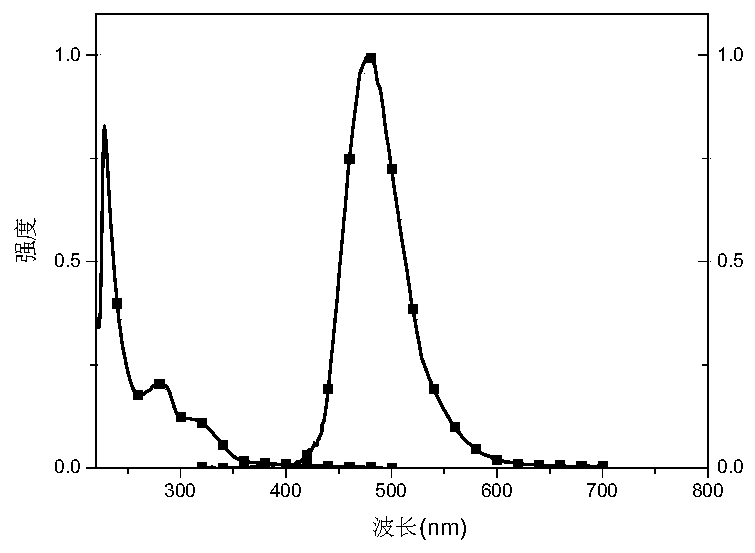

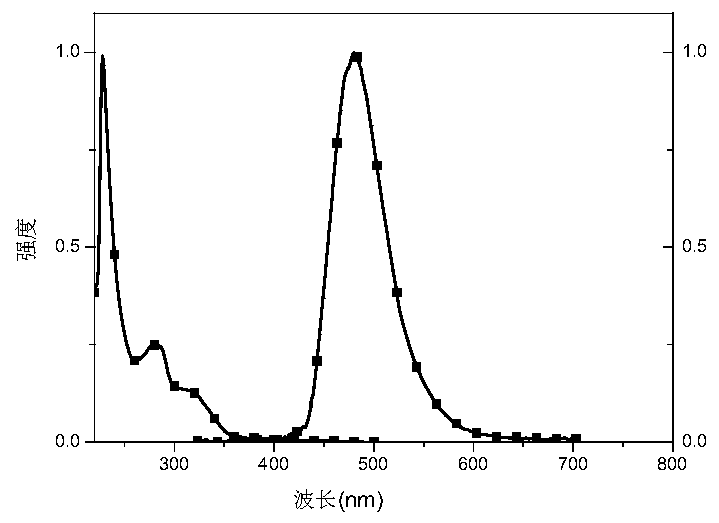

[0125] Example 2 Preparation of Thermally Excited Delayed Fluorescent Guest Materials 2a-2e

[0126] The experimental procedure is the same as in Example 1, except that the raw material fluoro-o-dibromobenzene used is 1,2-dibromo-3,4,5-trifluorobenzene, and the intermediate obtained in step (1) is 2a-1,2b -I, 2c-I, 2d-I, 2e-I; the intermediate obtained in step (2) is 2a-II, 2b-II, 2c-II, 2d-II, 2e-II; obtained in step (3) The products are 2a-2e.

[0127] The intermediates 2a-I, 2b-I, 2c-I, 2d-I, 2e-I structural formulas prepared in step (1) in Example 2 are:

[0128]

[0129] The intermediate 2a-II, 2b-II, 2c-II, 2d-II, 2e-II structural formula prepared in the step (2) is:

[0130]

[0131] The structural formula of the compounds 2a-2e prepared in Example 2 is:

[0132]

[0133] The data measured by mass spectrometry and elemental analysis of 2a to 2e are:

[0134] (2a) m / z: 1808.56 (100.0%), 1807.55 (72.9%), 1809.56 (68.4%), 1810.56 (33.3%), 1811.57 (10.3%), 18...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com