Intelligent garbage treatment environmental protection device

A technology of intelligent processing and environmental protection device, applied in grain processing and other directions, can solve the problems of complex composition, influence of processor performance and quality, waste of water and power resources, etc., to improve grinding effect and efficiency, prevent food waste from splashing, The effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

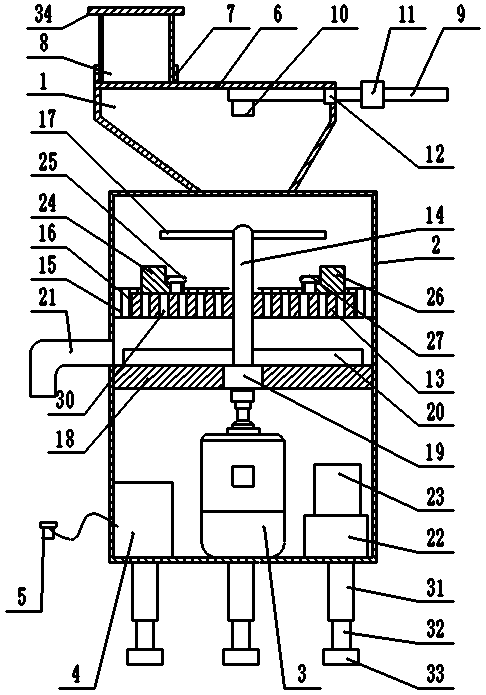

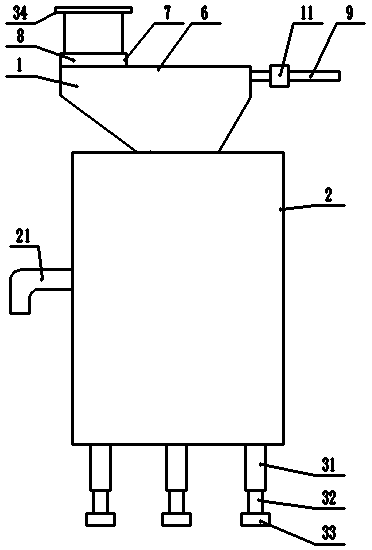

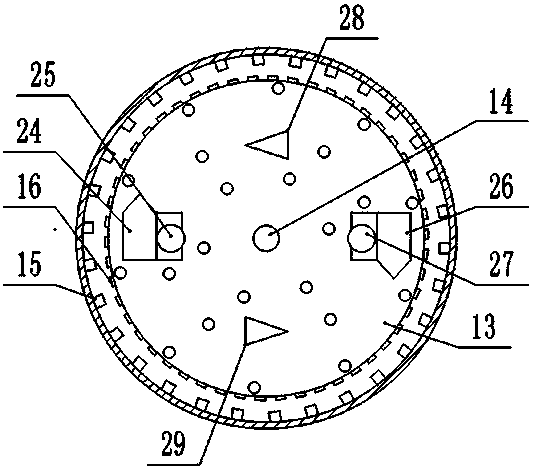

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 As shown, an environmental protection device for intelligently processing garbage includes a feeding inclined bucket 1, a casing 2, a drive motor 3, a controller 4, a switch button 5, a crushing and grinding device, a drainage device, and a water supply device. The inclined bucket 1 is fixed on the casing 2, and the upper end of the feeding inclined bucket 1 is fixed with a hopper plate 6 connected to the edge of the upper end of the feeding inclined hopper 1, and the hopper plate 6 is provided with a feeding port. The feed inlet is provided with a threaded connection cylinder 7 fixedly connected to the feed inlet, the threaded connection cylinder 7 is internally tapped with an internal thread, and the threaded connection cylinder 7 is provided with a feed cylinder 8. The outer cylindrical surface of the lower end of the feed cylinder 8 is tapped with an extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com