Efficient magnetic near infrared composite nanometer catalyst and preparation method thereof

A nano-catalyst and near-infrared light technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficult recycling, ineffective utilization, and limited application of photocatalysts , to reduce processing costs, achieve magnetic separation and recycling, and expand the range of photoresponse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of high-efficiency magnetic near-infrared light composite nano-catalyst, described catalyst is Fe 3 o 4 / β-NaYF 4 :Yb 3+ ,Tm 3+ / TiO 2 , the catalyst contains dodecahedral β-NaYF with a side length of 20 to 150 nm and a ridge length of 100 to 350 nm. 4 :Yb 3+ ,Tm 3+ , and spherical nano-Fe 3 o 4 Granular and Spherical Nano TiO 2 particles. The preparation method of this catalyst comprises the following steps:

[0028] (1) Mix Degussa P25, oleic acid, and ethanol with magnetic force and stir evenly, then add aqueous sodium hydroxide solution and stir evenly to obtain a mixed solution;

[0029] (2) Add ferrous ammonium sulfate hexahydrate into the above mixed solution and stir evenly with magnetic force;

[0030] (3) Add LnCl dropwise to the above mixed solution 3 solution, stirred magnetically for 20-40min, then slowly added NH 4 F aqueous solution and stirred for 50-70min to obtain the precursor, finally move the precursor into a sealed reaction ket...

Embodiment 1

[0037] Magnetic Fe 3 o 4 / β-NaYF 4 :Yb 3+ ,Tm 3+ preparation of

[0038] In this embodiment, preferably, 12.5mL of oleic acid and 12.5mL of ethanol were mixed with magnetic force for 30 minutes, and then 4mL of sodium hydroxide aqueous solution (containing 1.00g of sodium hydroxide) was added and stirred for 30 minutes. Then, 0.254 g of ferrous ammonium sulfate hexahydrate was added to the above mixed solution and magnetically stirred for 30 min. Then add YCl dropwise 3 (0.50M) 1.600mL, YbCl 3 (0.50M) 0.388 mL, TmCl 3 (0.01M) 0.600mL, magnetically stirred for 30min, then slowly added 2.0mL of NH 4 F (2.0M) aqueous solution and stirred for 60min, and finally moved the precursor into a 50mL sealed reaction kettle with polytetrafluoroethylene lining, placed in a blast dryer at 200°C for hydrothermal reaction for 8h, and then cooled naturally At room temperature, the product is separated by a magnet and washed with a 1:1 mixed solution of ultrapure water and absolute etha...

Embodiment 2

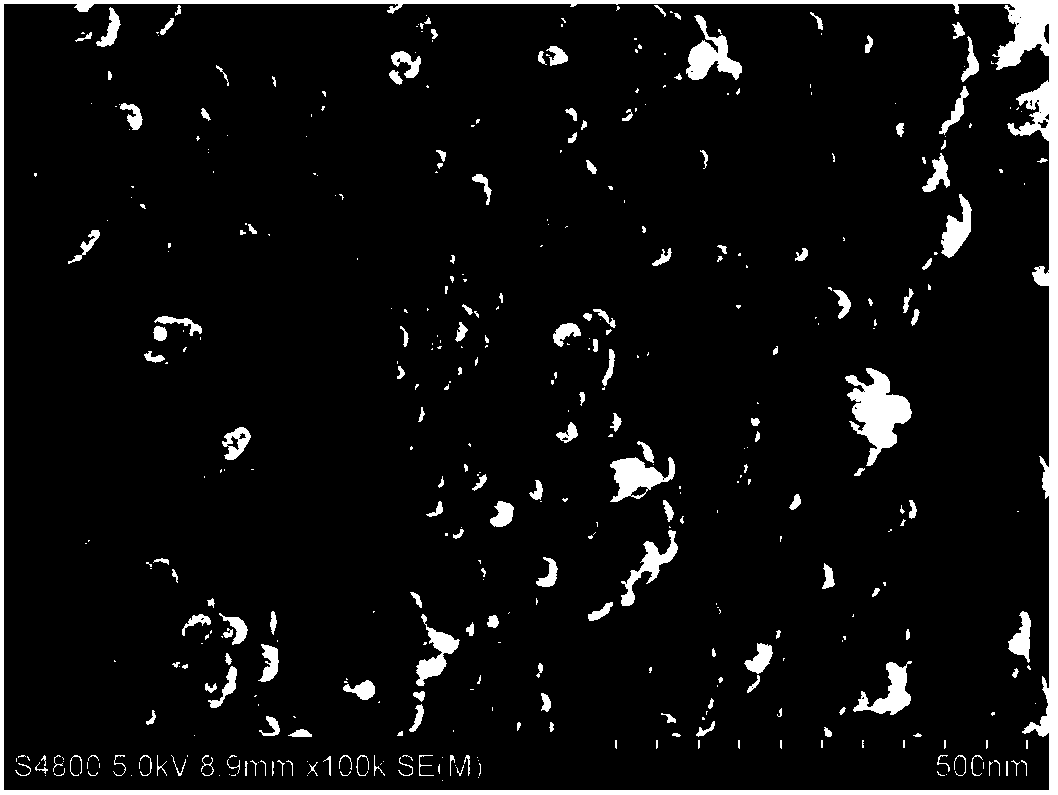

[0040] Fe 3 o 4 / TiO 2 preparation of

[0041] In this example, preferably, 0.06g Degussa P25, 12.5mL oleic acid, and 12.5mL ethanol were mixed and magnetically stirred for 30 minutes, then 4mL sodium hydroxide aqueous solution (containing 1.00g sodium hydroxide) was added and stirred for 30 minutes. Then add 0.254g of ferrous ammonium sulfate hexahydrate to the above mixed solution and stir it magnetically for 120min, finally move this precursor into a 50mL sealed reaction kettle with polytetrafluoroethylene lining, place it in a blast dryer Hydrothermal reaction at 200°C for 8 hours, then naturally cooled to room temperature, the product was separated by a magnet and washed with a 1:1 mixed solution of ultrapure water and absolute ethanol for 3 to 5 times, and then the precipitate was vacuum-dried at 50°C for 24 hours, after grinding High-efficiency magnetic near-infrared photocomposite nanocatalyst Fe 3 o 4 / TiO 2 , and its SEM photo is shown as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com