Electric neutrality control method of MEMS electro-spray thrusters

A control method and thruster technology, applied in electrical components, accelerators, etc., to achieve the effects of wide applicability, avoidance of charge accumulation, and flexible and diverse combinations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

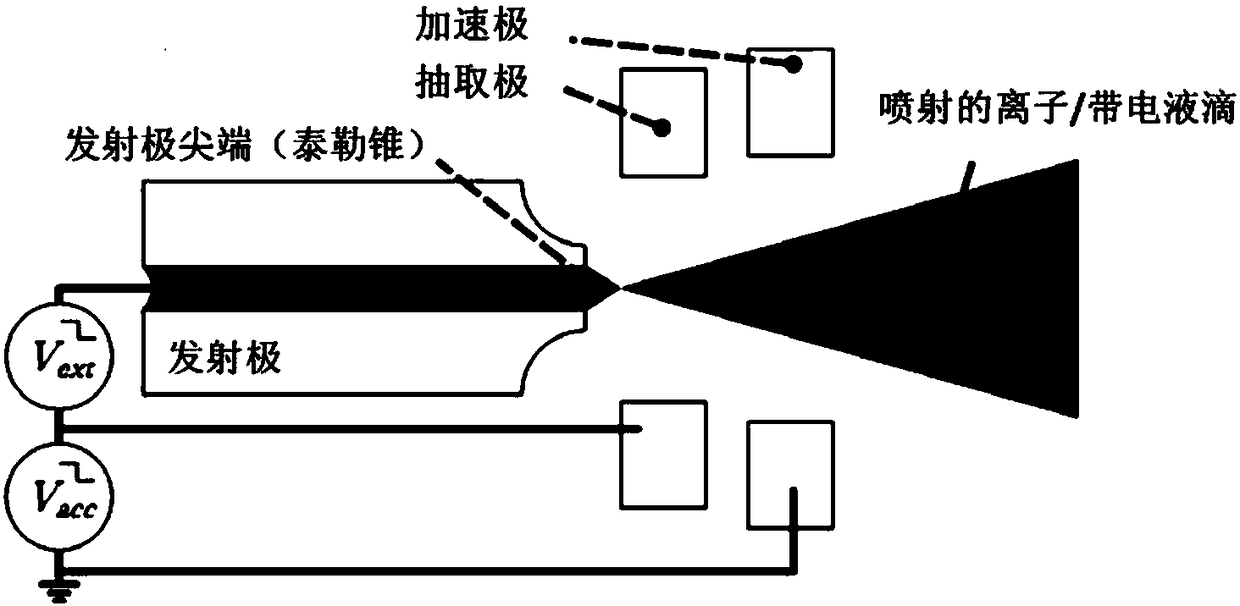

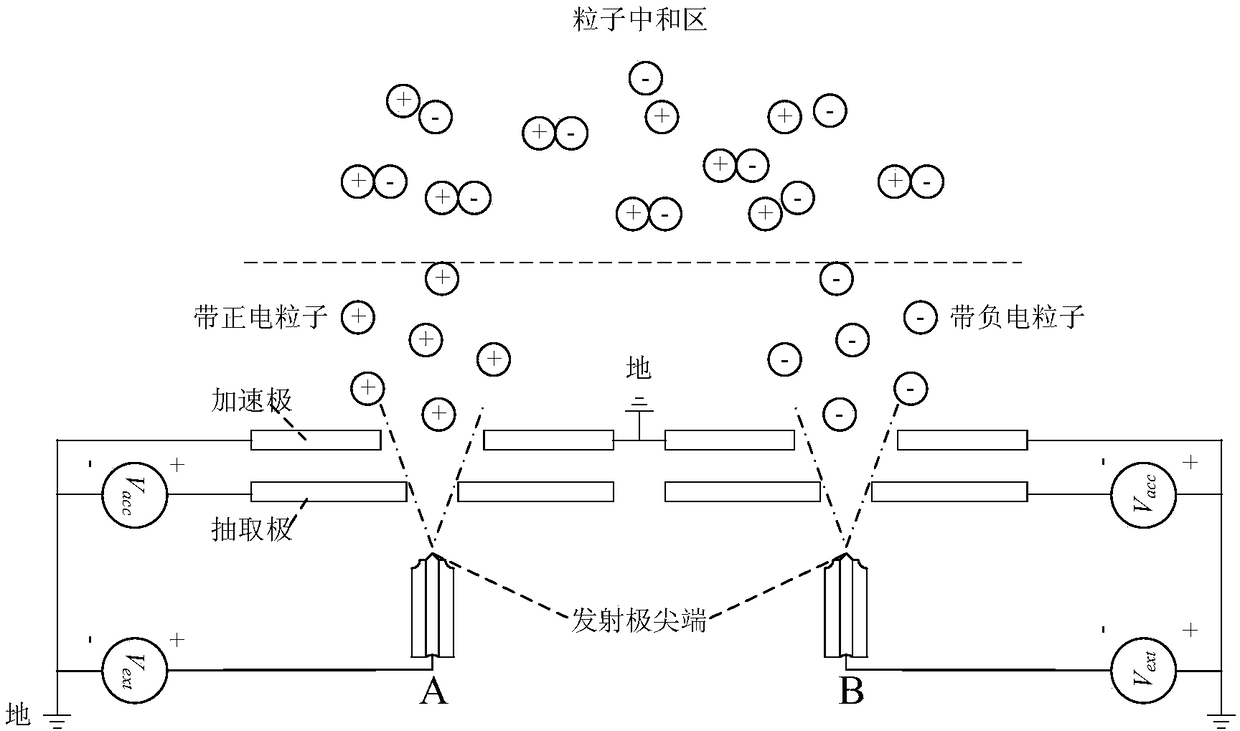

[0031] In this implementation, two thrusters are used to neutralize each other, the first thruster sprays positively charged particles, and the second thruster uses an extraction voltage of opposite polarity (V ext ) and accelerating voltage (V acc ) to cause it to spray negatively charged particles. Positively charged particles and negatively charged particles will be electrically neutralized in the neutralization zone. The first thruster and the second thruster are placed side by side, the acceleration plates of the first thruster and the second thruster are connected and common grounded, and the extraction plate and the emitter of the first thruster are connected to the extraction voltage source (the extraction voltage between the two electrodes for V ext ), the extraction plate and the accelerating plate are connected to the accelerating voltage source (the accelerating voltage between the two electrodes is V acc ); the extraction plate and emitter of the second thruste...

Embodiment 2

[0033] In this implementation, four thrusters are used to neutralize each other, and the four thrusters are arranged on a common ground. The first and fourth thrusters spray positively charged particles, and the second and third thrusters use oppositely polarized extraction voltages (V ext ) and accelerating voltage (V acc ) to make it spray negatively charged particles, and periodically change the polarity of the sprayed particles. Positively charged particles and negatively charged particles will be electrically neutralized in the neutralization zone. The first thruster and the second thruster are placed side by side in a horizontal direction, and the acceleration plate, the extraction plate and the emitter plate are respectively connected to each other in a horizontal direction. The first thruster and the third thruster are placed side by side vertically, and the acceleration plate, the extractor plate and the emitter plate are vertically corresponding to adjacent connecti...

Embodiment 3

[0036] In this implementation, eight thrusters are used to neutralize each other, and the eight thrusters are set up on the same ground. The first, third, sixth, and eighth thrusters spray positively charged particles, and the second, fourth, fifth, and seventh thrusters use opposite polarities. The extraction voltage (V ext ) and accelerating voltage (V acc) to cause it to spray negatively charged particles. Positively charged particles and negatively charged particles will be electrically neutralized in the neutralization zone. The first thruster, the second thruster, and the third thruster are arranged horizontally in sequence, and the accelerating plate, the extracting plate and the emitter plate are sequentially and correspondingly connected adjacently. The first thruster, the fourth thruster, and the sixth thruster are vertically arranged in sequence, and the acceleration plate, extraction plate and emitter plate are vertically connected to each other in sequence. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com