Power generation micro-nanocapsules and energy harvesting arrays for fluid transport pipelines

A technology of micro-nanocapsules and fluids, which is applied in the direction of friction generators, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., which can solve the difficulty of manufacturing micro-nanocapsules for power generation and the potential safety hazards And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

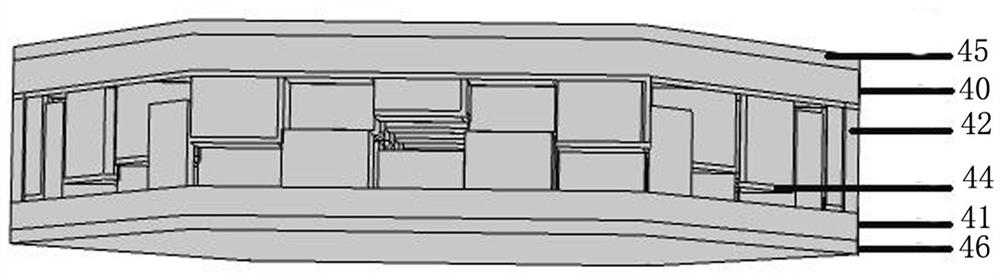

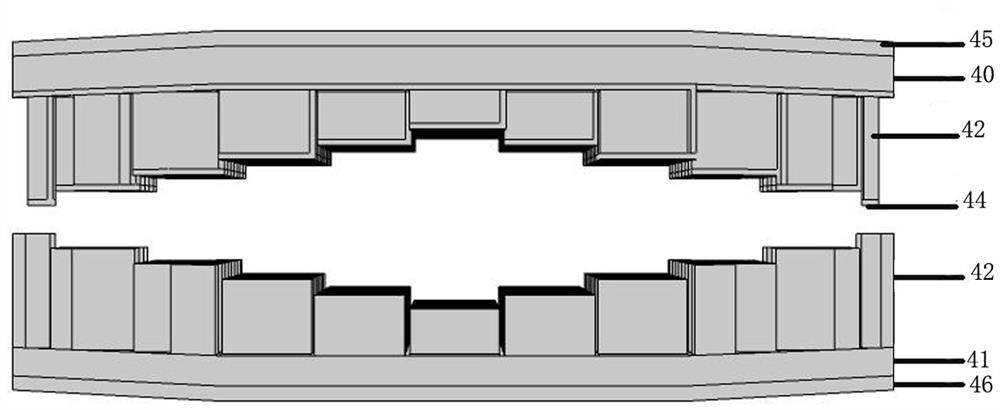

[0036] like Figures 1 to 4 As shown, the power generation micro-nanocapsule applicable to the fluid transport pipeline includes a friction power generation unit, and the friction power generation unit includes an upper friction part 40 and a lower friction part 41 opposite up and down, and the upper friction part 40 and the lower friction part 41 are both It is made of silica gel, and the upper friction part 40 and the lower friction part 41 both include a regular hexagonal bottom plate, and the opposite sides of the bottom plate of the upper friction part 40 and the bottom plate of the lower friction part 41 (ie The inner surfaces of both are provided with a plurality of protrusions 42 arranged in a distributed manner, and since there are intervals between the protrusions 42, the intervals between adjacent protrusions 42 form several depressions. part 43, the bottom surface of the recessed part 43 is the opposite surface of the bottom plate of the upper friction part 40 and ...

Embodiment 2

[0045] like Figure 5 and 6 As shown, the energy harvesting array formed by the distribution of the power generation micro-nanocapsule array suitable for the fluid transportation pipeline described in Example 1 is adopted, and the adjacent power generation micro-nanocapsules 1 in the energy harvesting array are all connected by side walls. Array distribution, the length of the energy harvesting array is between 10mm and 20mm, each power generation micro-nanocapsule 1 is embedded with a conductive interconnection wire 3 connected to the friction power generation unit and the piezoelectric power generation unit, and the adjacent The power-generating micro-nanocapsules 1 are electrically connected through interconnection wires. During manufacture, the energy-harvesting array is formed at one time using micro-nano manufacturing technology, such as photolithography, embossing, bonding, etc. Specifically, one-time embossing and manufacturing on a larger area can be selected, or mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com