High-pier steel girder pushing supporting device and construction method

A technology of supporting devices and steel girders, which is applied in bridges, bridge materials, bridge construction, etc., can solve the problems of high safety risk of the main structure, large structure consumption, and large construction period, so as to save manpower and material resources, uniform force transmission, and The effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

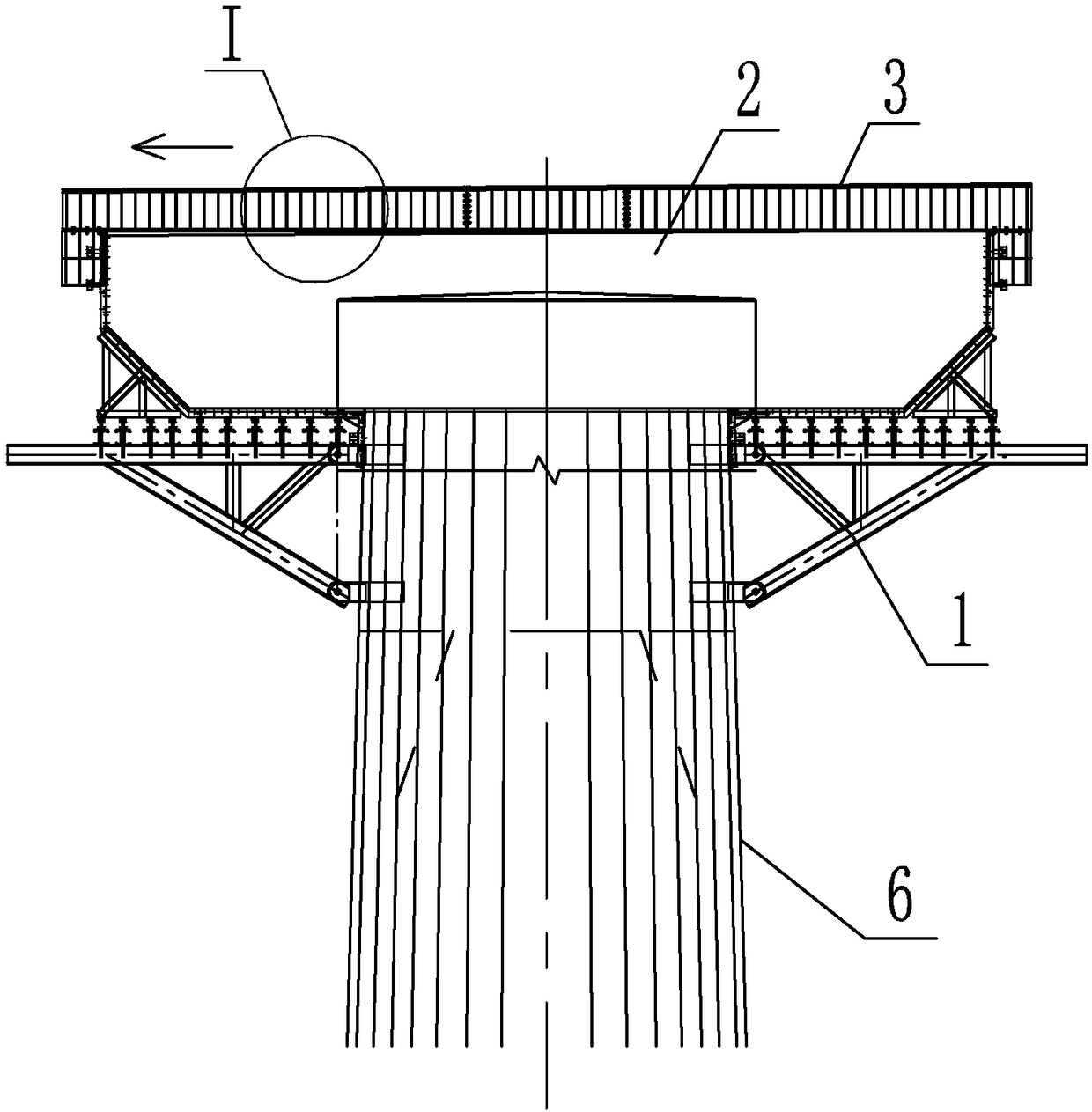

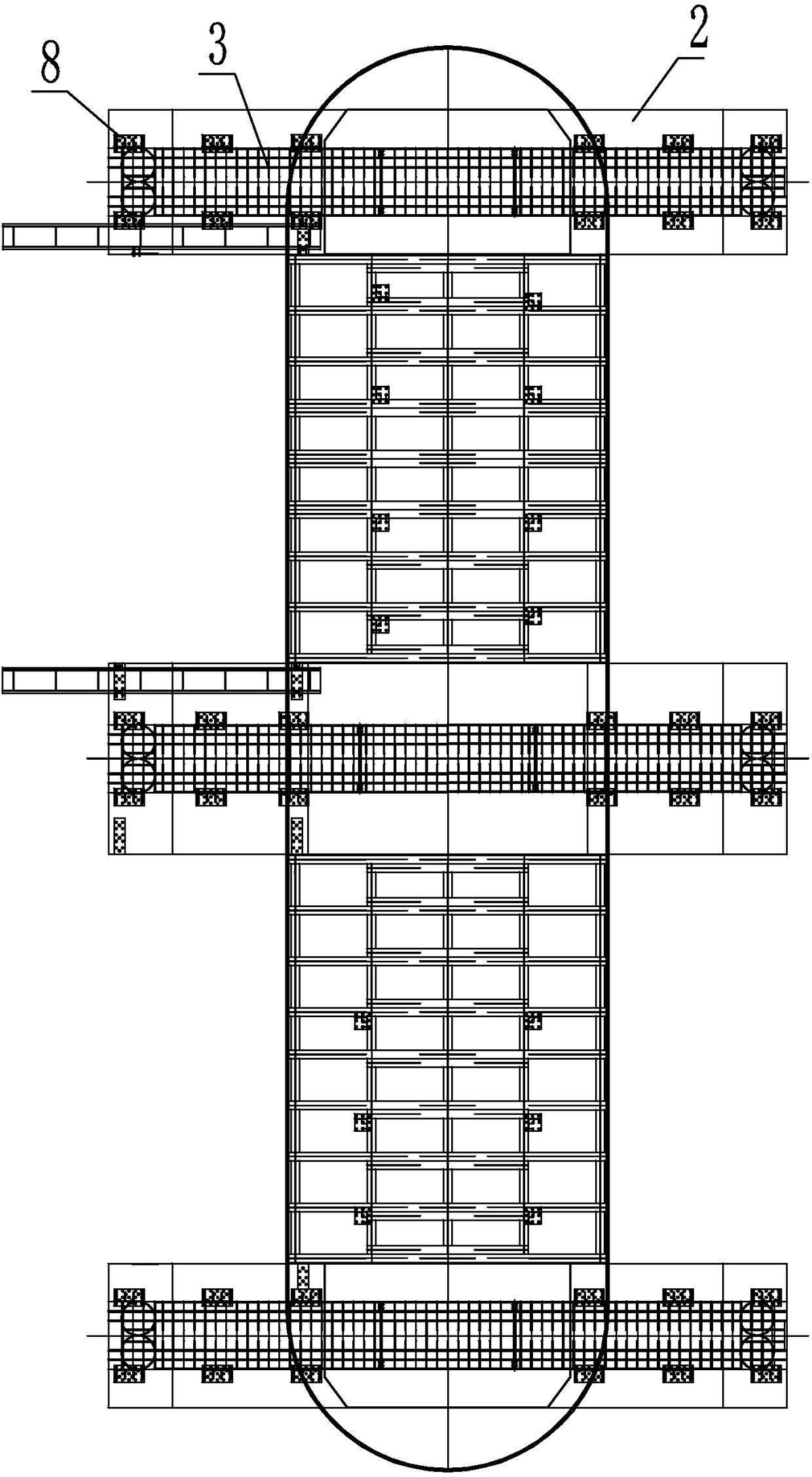

[0026] Specific implementation mode 1: Combination figure 1 with image 3 To illustrate this embodiment, this embodiment includes three concrete joists 2 and three steel slide beams 3;

[0027] Above the pier column 6, there are three parallel and evenly spaced concrete joists 2. The pier column 6 and each concrete joist 2 are connected by a plurality of pier cap steel bars 9, and each concrete joist 2 is provided with a steel skeleton inside. Reinforcing steel meshes 7 are arranged in the reinforcing steel framework, and the reinforcing steel frameworks are fixed to the steel slide beam 3, and each reinforcing steel mesh 7 is fixed to each pier cap reinforcing steel 9 together.

[0028] In this embodiment, pier cap steel bars 9 are provided, and each steel mesh 7 is fixed to each pier cap steel bar 9 to enhance the connection strength between the joist and the pier column 6.

specific Embodiment approach 2

[0029] Specific implementation manner two: combination figure 1 To illustrate this embodiment, the concrete joist 2 in this embodiment is rectangular, the bottom of the two sides of the concrete joist 2 in the length direction is chamfered, and the bottom of the concrete joist 2 protruding from both sides of the pier 6 is provided with Bracket 1.

[0030] In this embodiment, the bracket 1 plays a supporting role when the concrete joist 2 is poured, and also serves as an operating platform.

[0031] The other composition and connection relationship are the same as in the first embodiment.

specific Embodiment approach 3

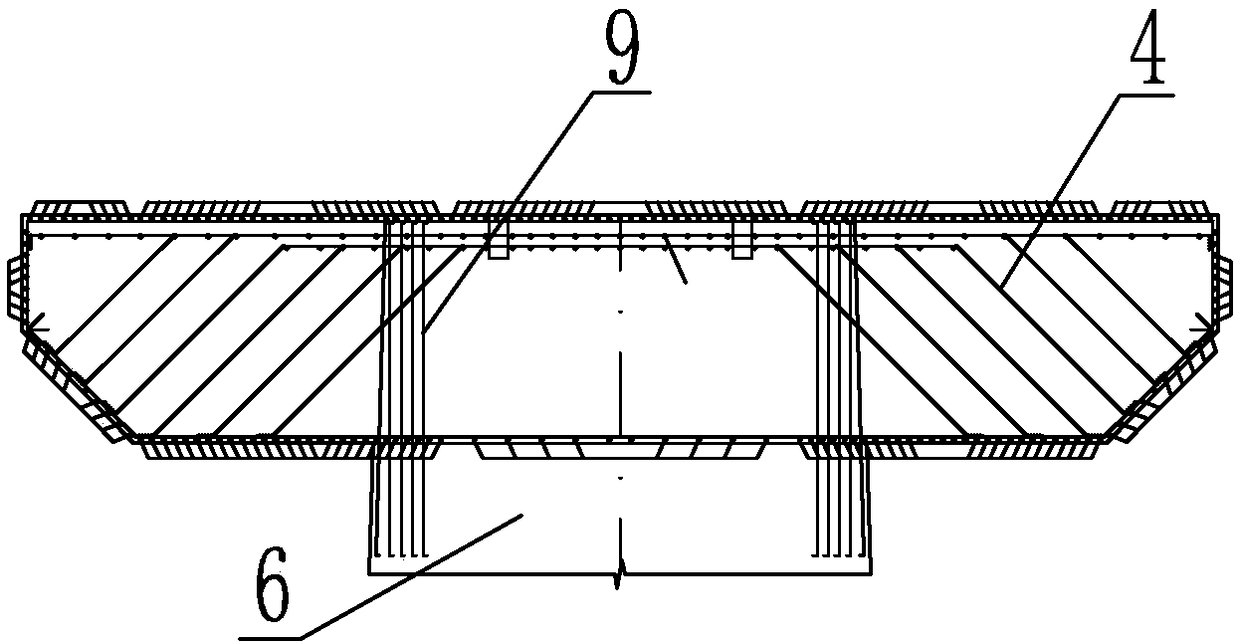

[0032] Specific implementation mode three: combination figure 1 with figure 2 To illustrate this embodiment, the shape of the reinforcement skeleton of the concrete joist 2 and the concrete joist 2 are the same, and the reinforcement skeleton of the concrete joist 2 is provided with oblique-stayed steel bars 4 connected to the reinforcement skeleton.

[0033] This embodiment improves the bending strength of both ends of the concrete joist 2.

[0034] The other composition and connection relationship are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com