Method for preparing liquid hydrocarbons by Fischer-Tropsch oligomerization coupled catalytic conversion of olefin-rich synthesis gas

A catalytic conversion and Fischer-Tropsch catalyst technology, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, can solve the problems that are not conducive to improving the octane number of fuels, and achieve full utilization of green and low-carbon resources, process concentration, and improvement of comprehensive carbon The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the coupling catalytic system adopts oligomerization molecular sieve catalyst HZSM-5 and Fischer-Tropsch catalyst FeMn, wherein HZSM-5 is a commercially available microporous molecular sieve catalyst, wherein m(Si):m(Al)=20:1, HZSM -5 is calcined at 550°C, pressed into tablets and sieved to obtain finished granules of 40-60 mesh (that is, with a particle size of 0.25-0.38 mm) for future use.

[0028] The FeMn catalyst (m(Fe):m(Mn)=2:1) was prepared by co-precipitation method, and the specific preparation steps were as follows: Fe(NO3 ) 3 9H 2 O and Mn(NO 3 ) 2 Dissolve in deionized water, stir until a homogeneous solution is formed, in which the mass ratio of Fe to Mn is 2:1; heat the solution to 80°C and maintain this temperature, then slowly drop in a mass fraction of 25 % ammonia solution until the pH of the solution is 8.0. With the addition of ammonia water, dark brown precipitates are produced in the solution. After the dark brown precipi...

Embodiment 2

[0033] Catalyst: The preparation method of HZSM-5 and FeMn is the same as that of Example 1. The two kinds of catalyst powders of equal mass are stirred and ground in a mortar and mixed evenly, and the obtained composite catalyst powder is granulated to obtain 40~60 mesh particles, and 1g of the composite catalyst powder is The particles are mixed with 1g of quartz sand and filled into the fixed bed reaction tube.

[0034] Coupled Catalytic Reaction: Pre-reduction of Coupled Catalytic System in Syngas H 2 Carried out in an atmosphere with a molar ratio of 1:1 to CO, pressure 0.1MPa, syngas space velocity 3000mL / g·h, temperature 300°C, reduction for 12h. The reaction raw material gas adopts the simulated mixed gas similar to the olefin-rich syngas produced by the catalytic cracking of bio-oil, and its gas composition is as follows: the volume ratio of each component gas is C 3 h 6 / CO / H 2 / N 2 =20 / 30 / 10 / 40, the reaction conditions are temperature 280°C, pressure 4.0MPa, raw...

Embodiment 3

[0037] Catalyst: The preparation method of HZSM-5 and FeMn is the same as that in Example 1, and the two catalyst particles of equal mass 40-60 mesh are evenly mixed to obtain composite catalyst particles of 40-60 mesh, and 1 g of the composite catalyst particles is mixed with 1 g of quartz sand. Fill the fixed bed reaction tube.

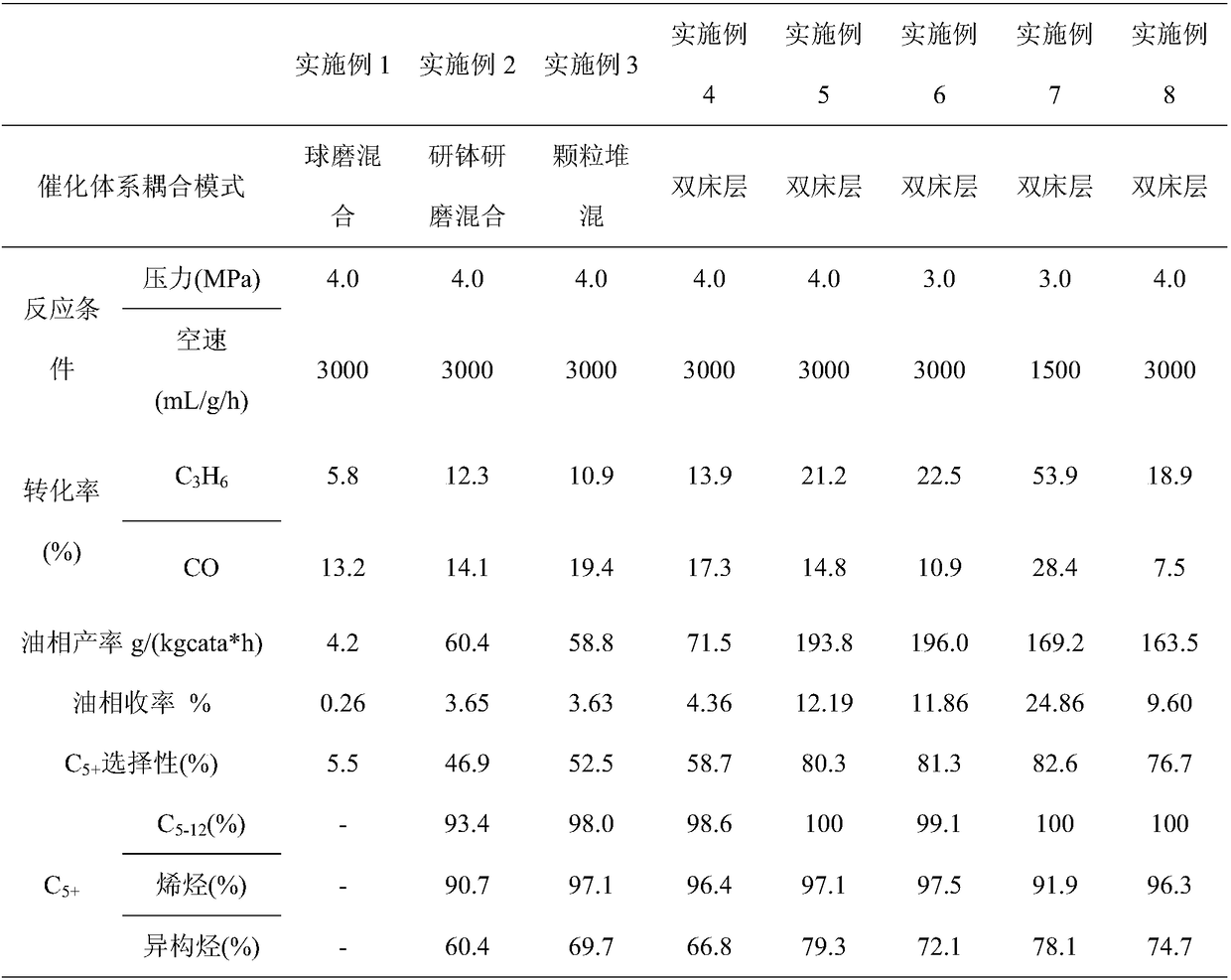

[0038] Coupled catalytic reaction: the reaction conditions are the same as in Example 1, and the final product C 5+ The yield reaches about 59g / (kgcata*h), C 5+ The selectivity reaches about 52%, C 5+ C in the product 5 - C 12 The selectivity of gasoline section is over 95%, while the selectivity of olefins is 97%, and the selectivity of isomeric hydrocarbon is about 70%. Its concrete result is shown in Table 1, and Table 1 is the yield of embodiment 1~8 catalyst coupling mode, reaction condition and product and C 5+ Selective comparison results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com