A method for modifying three-dimensional graphene-confined high-capacity hydrogen storage materials with iron-based catalysts

A technology of iron-based catalysts and hydrogen storage materials, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems that have not been seen, and achieve the effect of simple method, increased loading area, and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

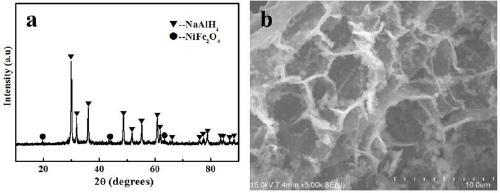

[0024] Weigh Fe(NO 3 ) 3 9H 2 The powder of O and polyvinylpyrrolidone with a mass ratio of 1:1 is dissolved in deionized water to form a mixed solution, which is kept in a blast drying oven at 75°C for 3 hours until it is completely dry, and then the dried product is ground into a powder. The powder was transferred to a tube furnace in a nitrogen atmosphere at 700 °C for 2 h to obtain a three-dimensional graphene composite material modified with iron carbide catalyst, and 0.015 mg of iron carbide catalyst modified three-dimensional graphene and 0.002 mg of dibutyl magnesium were dissolved in heptane and ring In the hexane mixed solution, the reaction was carried out at 200°C under the hydrogen pressure of 3MPa, and the reaction time was kept at 24h. After centrifugal vacuum drying, the iron carbide catalyst modified three-dimensional graphene and MgH 2 Composite hydrogen storage materials.

Embodiment 2

[0026] Weigh Fe(NO 3 ) 3 9H 2 O and polyvinylpyrrolidone mass ratio of 0.8:1 powder is dissolved in deionized water to make a mixed solution, kept in a blast drying oven at 75 ° C for 3 hours until completely dry, and then the dried product is ground into a powder. The powder was transferred to a tube furnace in a nitrogen atmosphere at 750°C for 1.5 h to obtain a three-dimensional graphene composite material modified with iron carbide catalyst, and 0.02 mg of iron carbide catalyst modified three-dimensional graphene and 0.003 mg of dibutyl magnesium were dissolved in heptane and In the cyclohexane mixed solution, the reaction was carried out at 200°C under the hydrogen pressure of 2.5MPa, and the reaction time was kept at 20h. After centrifugal vacuum drying, the iron carbide catalyst modified three-dimensional graphene and MgH 2 Composite hydrogen storage materials.

Embodiment 3

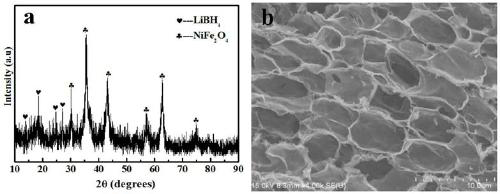

[0028] Weigh Fe(NO 3 ) 3 9H 2 O and polyvinylpyrrolidone mass ratio of 1.2:1 powder is dissolved in deionized water to make a mixed solution, kept in a blast drying oven at 75 ° C for 3 hours until completely dry, and then the dried product is ground into a powder. The powder was transferred to a tube furnace in a nitrogen atmosphere at 700°C for 2 hours to obtain an iron carbide catalyst-modified three-dimensional graphene composite material, and the iron carbide catalyst-modified three-dimensional graphene composite material was immersed in the dissolved LiBH 4 In tetrahydrofuran (THF) solution, ultrasonically stirred for 30min, vacuum-dried at room temperature, and then slowly heated to 150°C to remove the solvent to obtain three-dimensional graphene-confined LiBH modified with iron carbide catalyst 4 high-capacity hydrogen storage materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com