A kind of preparation method and application of fe-ti binary oxide adsorbent for removing antimony

A binary oxide and adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, water pollutants, etc., can solve problems such as lack of adsorbent, and achieve high removal efficiency, easy control, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

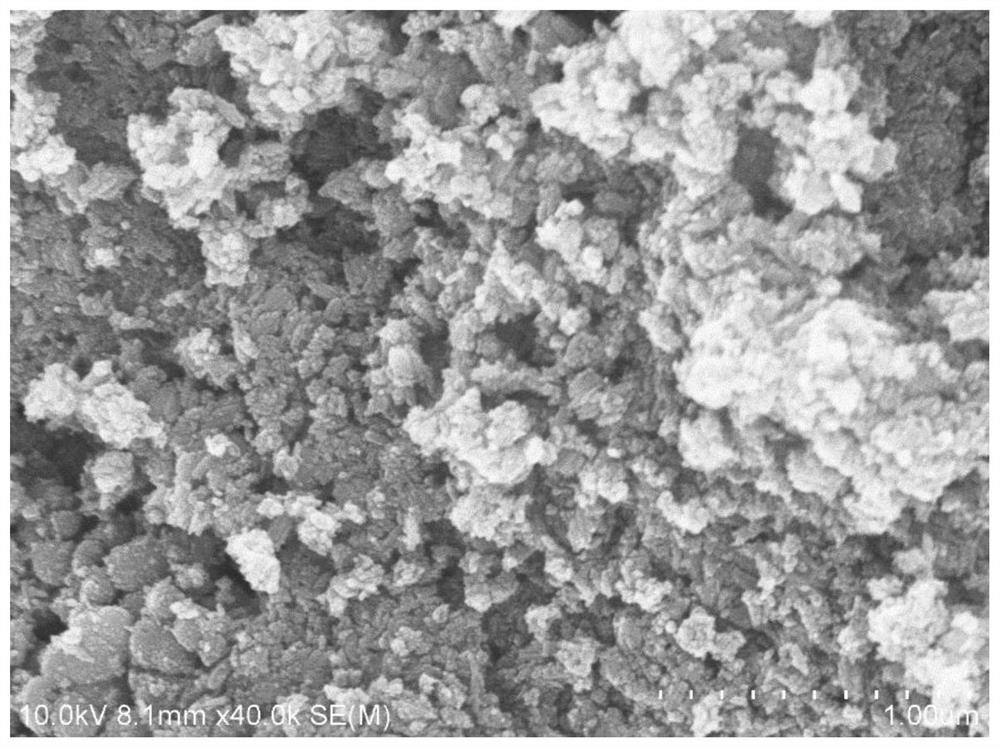

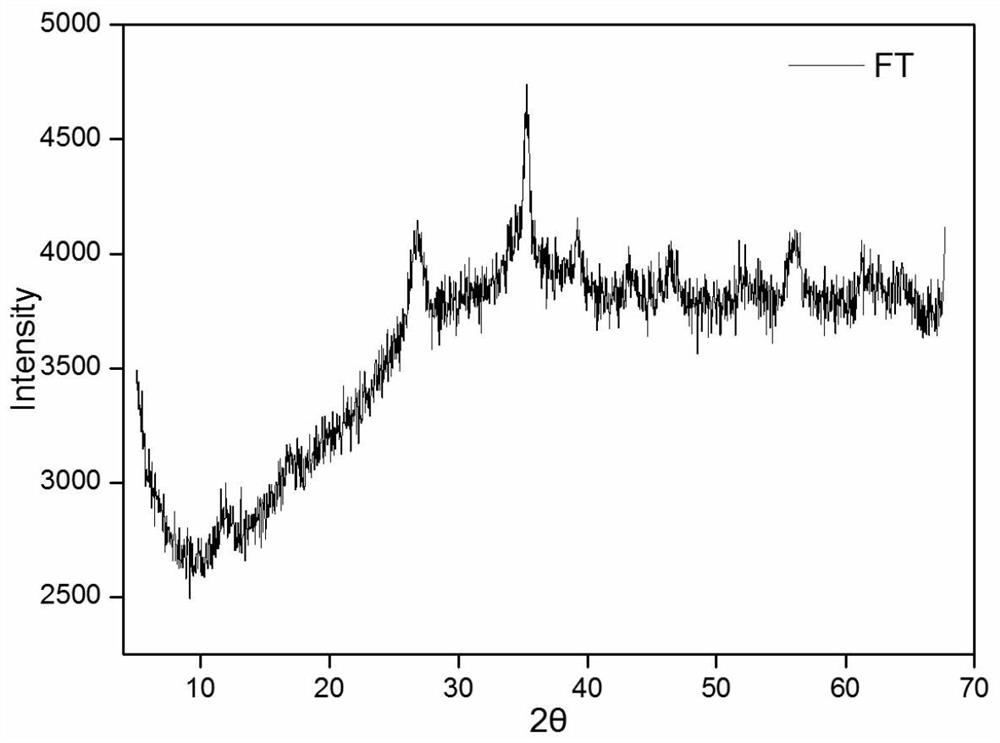

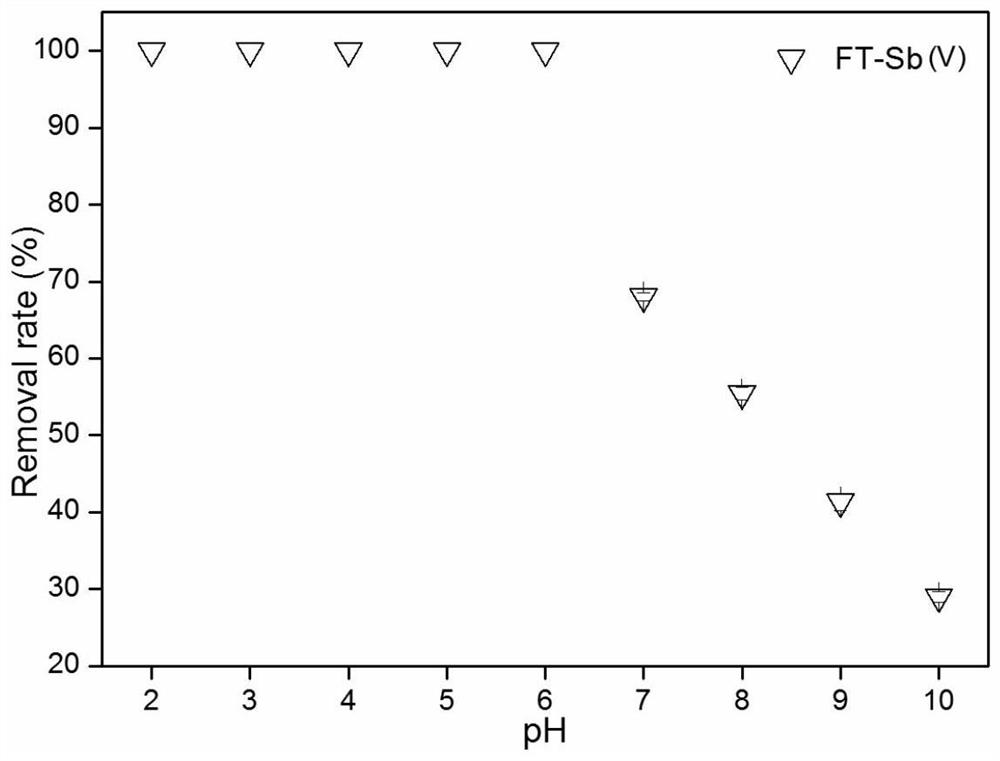

[0029] Embodiment 1: a kind of preparation method of the Fe-Ti binary oxide adsorbent for antimony of the present invention (such as figure 1 shown)

[0030] Under the state of magnetic stirring (100rpm), 0.25mol titanium tetrachloride (TiCl 4 ) was slowly injected into 1L of 0.5M ferric chloride (dissolved in 0.1M HCl) solution; at the same time, 1M NaOH solution was slowly added dropwise until the pH value remained at 6.00±0.02, and the mixed solution was ultrasonically dispersed for 30 minutes to obtain a suspension. The suspension was stirred at a speed of 200rpm for 0.8h; then the gelatinous yellow-brown precipitate was aged in the mother liquor for 4 days; an activated layer with strong adsorption capacity was formed on the surface of the adsorbent material, and the precipitate was separated from the solid and liquid , the brown-yellow precipitate was washed 5 times with deionized water, and the volume ratio of the volume of each washing water to the reaction system was...

Embodiment 2

[0031] Embodiment 2: a kind of preparation method of Fe-Ti binary oxide adsorbent for antimony of the present invention (such as figure 1 shown)

[0032] In the state of magnetic stirring (100rpm), slowly inject 1mol of titanium sulfate into 1L of 0.2M ferric sulfate (dissolved in 0.1M HCl) solution; at the same time, slowly add 1M NaOH solution dropwise until the pH value remains at 5.0, and ultrasonically disperse the mixture After 10 minutes, the suspension was obtained, and the suspension was stirred at a speed of 200 rpm for 0.5 hours; then the gelatinous yellow-brown precipitate was aged in the mother liquor for 2 days; the surface of the adsorption material was activated to generate a strong adsorption capacity. layer, precipitation and solid-liquid separation, the brown-yellow precipitate was washed 5 times with deionized water, the volume ratio of each washing water to the reaction system was 2:1, until the pH of the washed water was 7.0, the suspended solid was centr...

Embodiment 3

[0033] Embodiment 3: a kind of preparation method of Fe-Ti binary oxide adsorbent for antimony of the present invention (as figure 1 shown)

[0034] Under magnetic stirring (100rpm), slowly inject 1mol of titanium nitrate into 1L of 5M ferric nitrate (dissolved in 0.1M HCl) solution; at the same time, slowly add 1M NaOH solution dropwise until the pH value remains at 7.0, and ultrasonically disperse the mixture for 50min After obtaining the suspension, the suspension is 200rpm according to the rotating speed, and continues to stir for 1h; then the gelatinous yellow-brown precipitate is aged in the mother liquor for 6 days; the surface of the adsorption material is made to generate an active layer with strong adsorption capacity. Precipitation and solid-liquid separation, wash the brown-yellow precipitate with deionized water 5 times, the volume ratio of each washing water to the reaction system is 2:1, until the pH of the washed water is 7.0, the suspended solid is centrifuged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com