Brewing core of coffee machine

A technology of coffee machine and ball screw pair, which is applied in the field of coffee machine components, can solve the problems of increasing the probability of water leakage at the joint, increasing the manufacturing cost, and slow brewing speed, so as to improve the working stability and service life , Reduce the probability of water leakage, and facilitate the effect of sealing treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

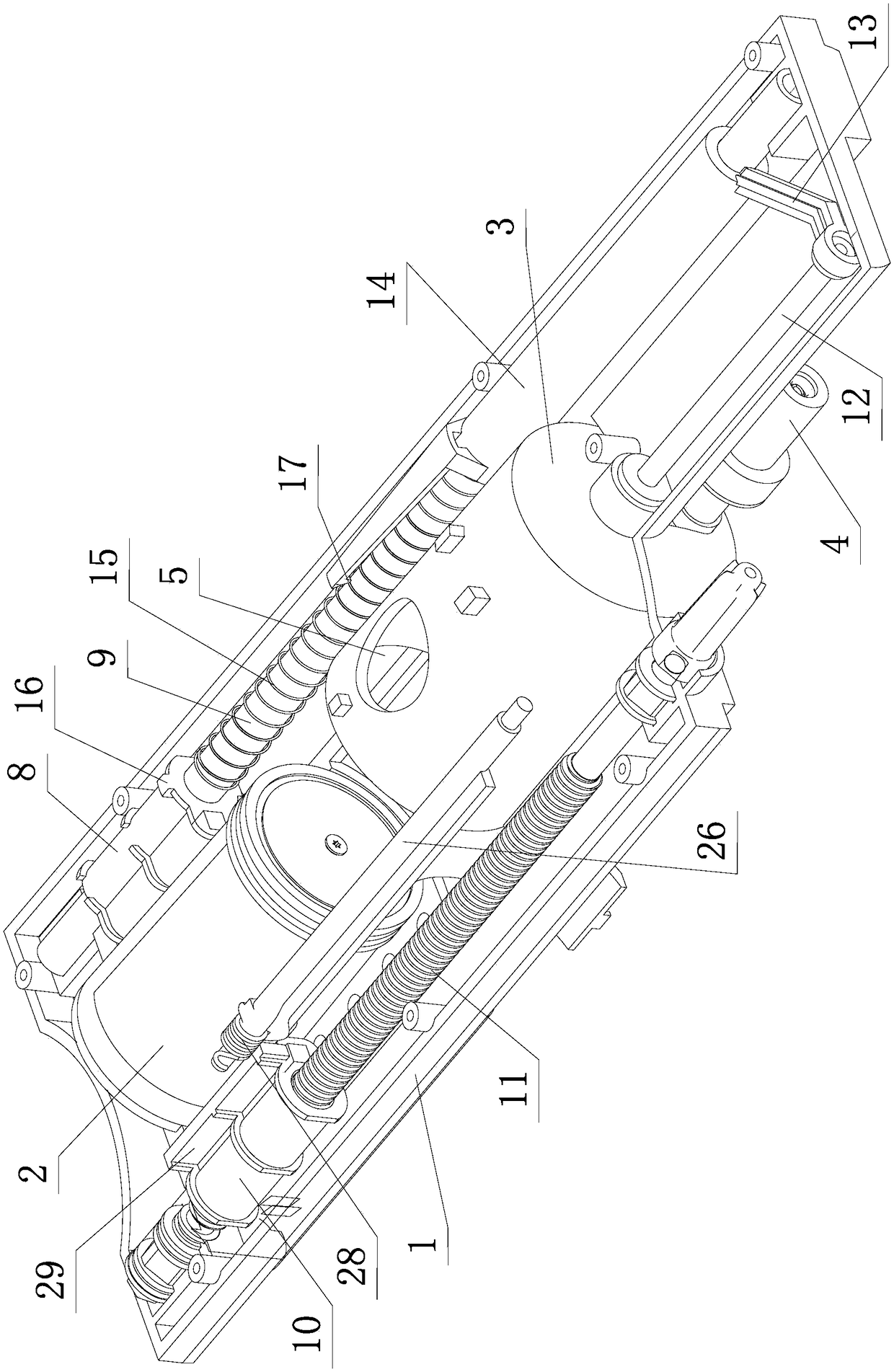

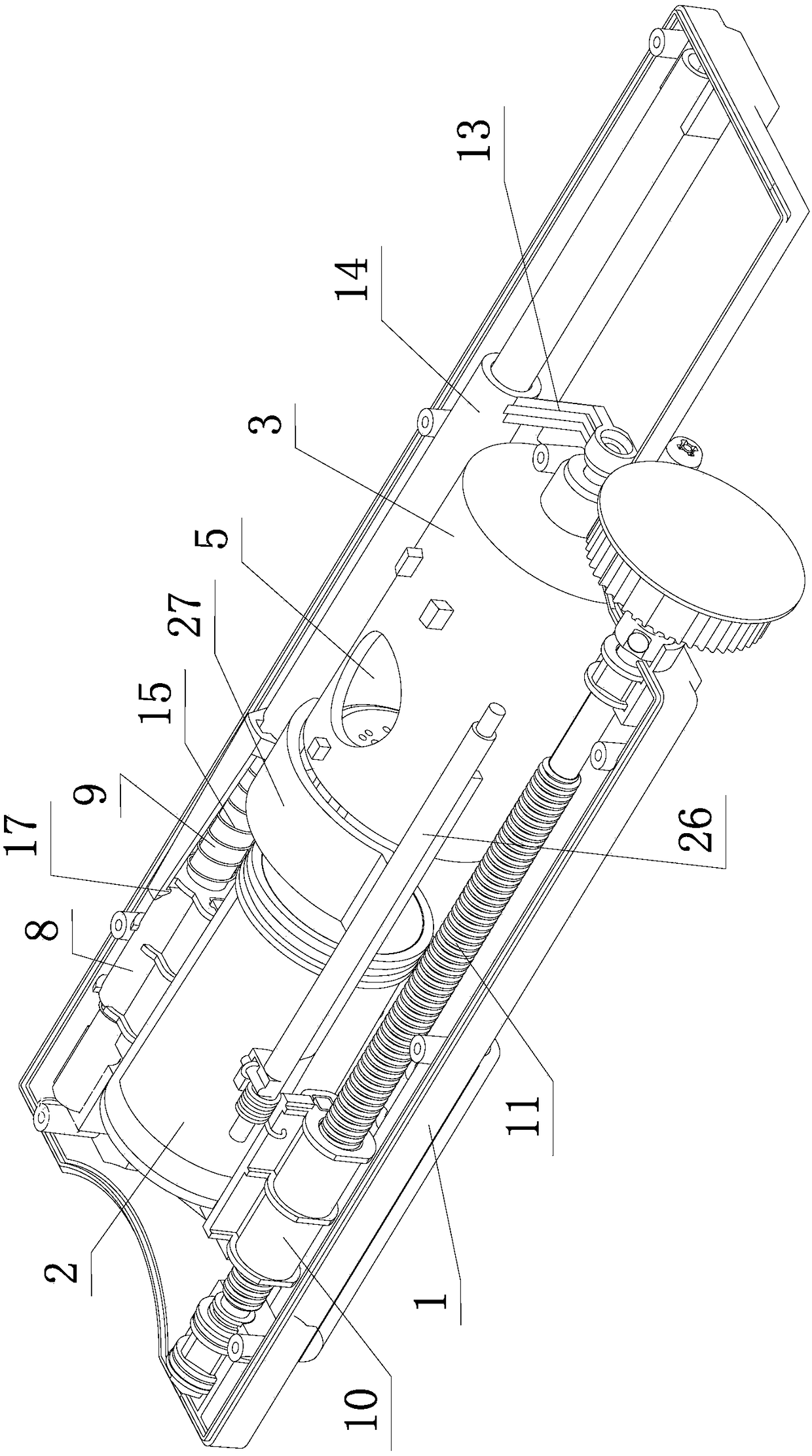

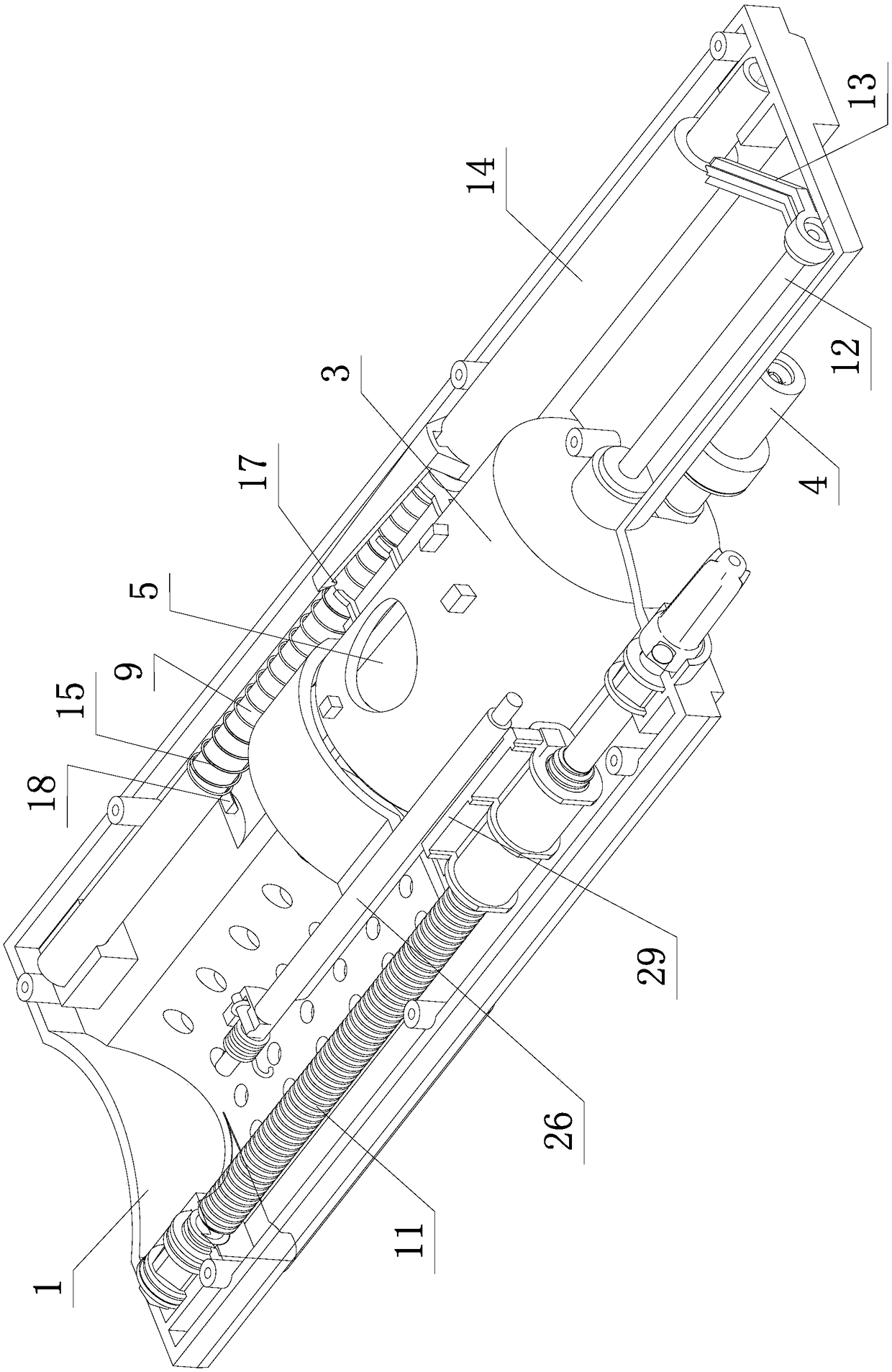

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the brewing core of the coffee machine of the present invention includes a support 1, a top 2, a brewer 3, a water inlet pipe 4 and a ball screw pair. Let us first unify a concept of direction. In this application, the direction close to the brewer 3 is the front and the direction close to the top 2 is the back. The brewer 3 is fixed to the bracket 1, and the brewer 3 is provided with a brewing chamber with an opening facing the top 2, that is to say, the brewer 3 opens toward the rear, and the powder drop port 5 is located near the opening of the brewer 3, and the vicinity refers to, The powder drop port 5 is located at the rear of the brewer.

[0026] And the ball screw pair is installed on the support 1, and the plug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com