LED epitaxial structure and preparation method thereof

A technology of epitaxial structure and epitaxial layer, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve problems such as affecting LED brightness and weakening luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

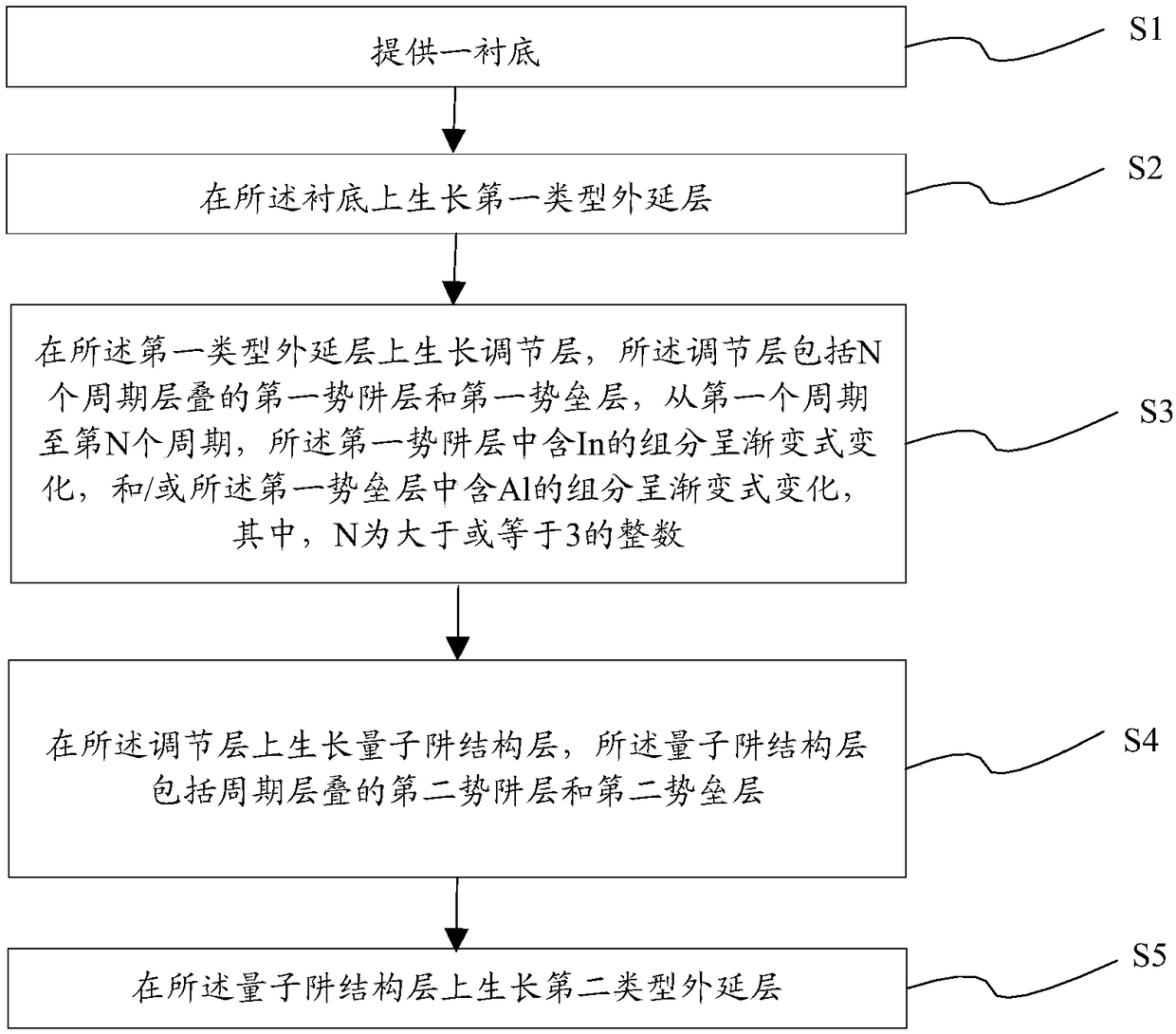

[0051] Correspondingly, the present invention also provides a method for preparing an LED epitaxial structure, such as figure 1 Shown: described preparation method comprises the following steps:

[0052] Step S1, providing a substrate;

[0053] Step S2, growing a first type epitaxial layer on the substrate;

[0054] Step S3, growing an adjustment layer on the first type epitaxial layer, the adjustment layer includes a first potential well layer and a first barrier layer stacked in N periods, from the first period to the Nth period, so The composition containing In in the first potential well layer changes gradually, and / or the composition containing Al in the first barrier layer changes gradually, wherein N is an integer greater than or equal to 3;

[0055] Step S4, growing a quantum well structure layer on the adjustment layer, the quantum well structure layer including a second potential well layer and a second potential barrier layer stacked periodically;

[0056] Step S...

Embodiment 1

[0060] see figure 1 , firstly, step S1 is performed to provide a substrate 10, such as figure 2 shown. The substrate 10 may be a sapphire substrate, a gallium nitride substrate, an aluminum nitride substrate, a silicon substrate or a silicon carbide substrate, etc. The substrate 10 in this embodiment is preferably a sapphire substrate.

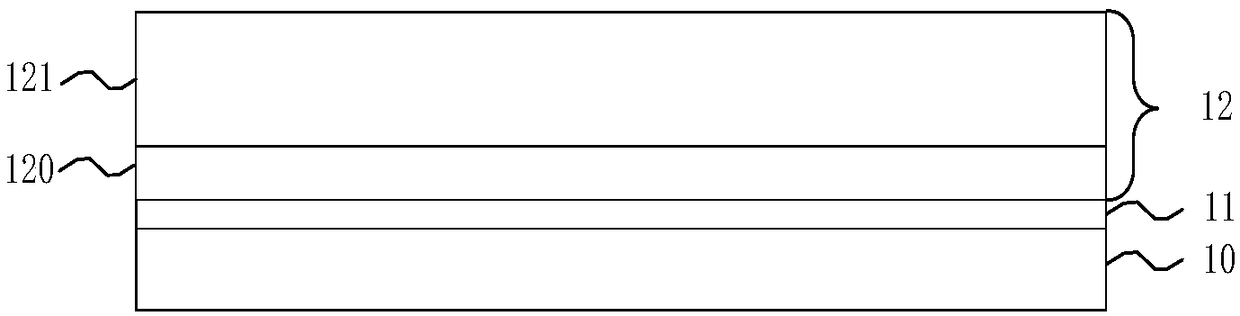

[0061] Then, if figure 1 As shown, step S2 is performed to grow the first type epitaxial layer 12 on the substrate 10, such as image 3 shown. The epitaxial growth method can be MOCVD (metal organic chemical vapor deposition) method, CVD (chemical vapor deposition) method, PECVD (plasma enhanced chemical vapor deposition) method, MBE (molecular beam epitaxy) method or HVPE (hydride vapor phase epitaxy) method etc. In this embodiment, the epitaxial growth method may preferably be the MOCVD method, which is not limited here. In the actual epitaxial growth process, in order to improve the crystal quality of LED epitaxial growth, a nucleatio...

Embodiment 2

[0071] see Figure 7 , where with Figure 2-Figure 6 The same reference numerals denote the same structures as those of the first embodiment. The preparation method of the second embodiment is basically the same as the preparation method of the first embodiment, the difference is that in step S3, as Figure 7 As shown, the adjustment layer 13' includes N periodic stacked first potential well layers and first barrier layers, N is an integer greater than or equal to 3, and the growth temperature of the adjustment layer 13' can be controlled at 700 degrees Celsius to Between 900 degrees Celsius, such as 800 degrees Celsius or 850 degrees Celsius; the thickness of the first potential well layer is 1.0 nm to 3.0 nm, and the thickness of the first barrier layer is 2.0 nm to 4.0 nm. The first potential well layer is In x Ga 1-x N, the first barrier layer is Al y Ga 1-y N, wherein the composition x of In is between 0% and 25%, and the composition y of Al is between 0% and 40%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com