Au-supported mesoporous structure In2O3 nano sensitive material based NO2 sensor, preparation method and application thereof

A sensitive material and mesoporous structure technology, applied in nanotechnology for sensing, nanotechnology for materials and surface science, material resistance, etc., can solve the problems of increasing respiratory diseases and throat morbidity, and achieve appropriate Suitable for mass production, simple manufacturing process, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

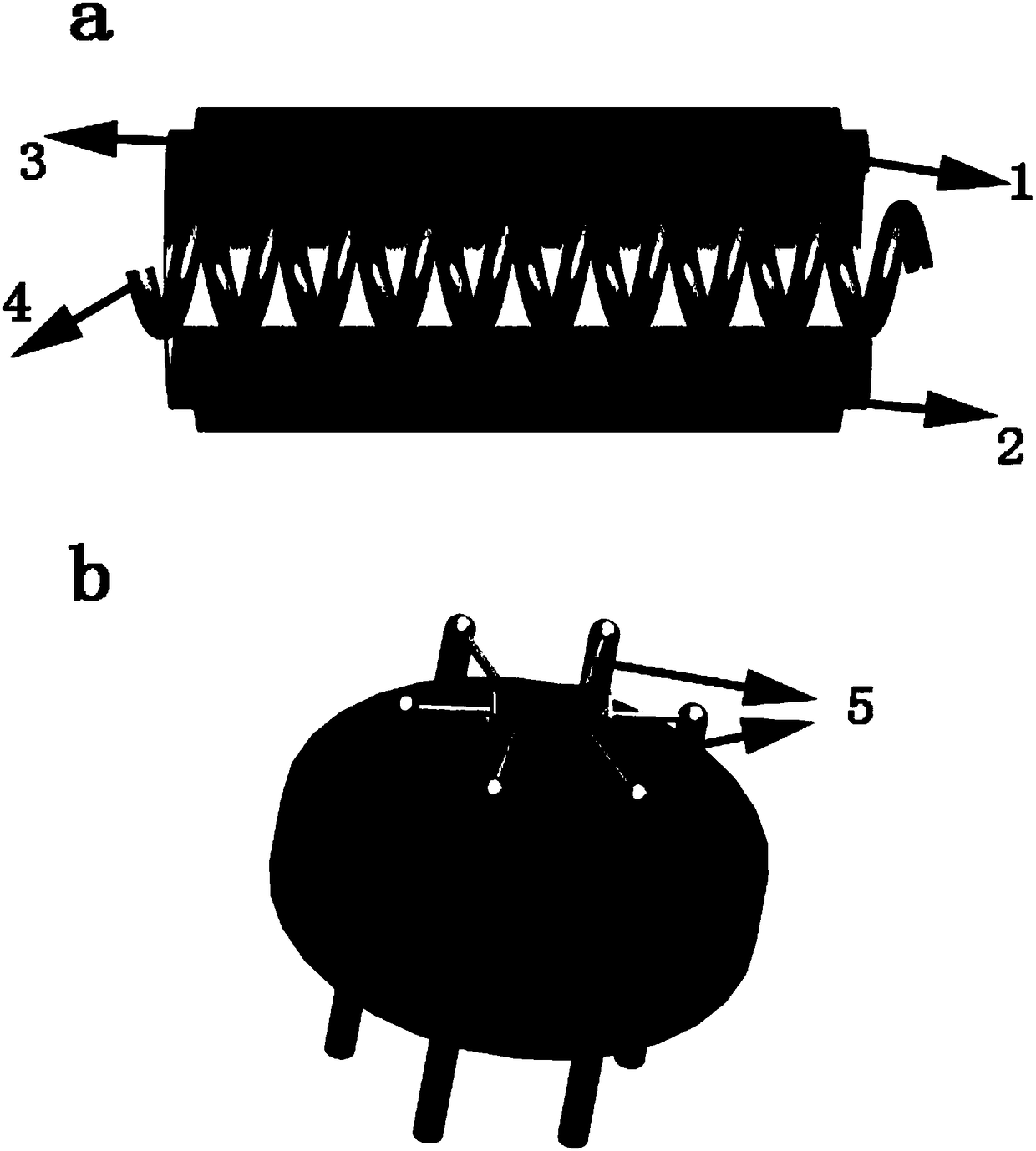

Method used

Image

Examples

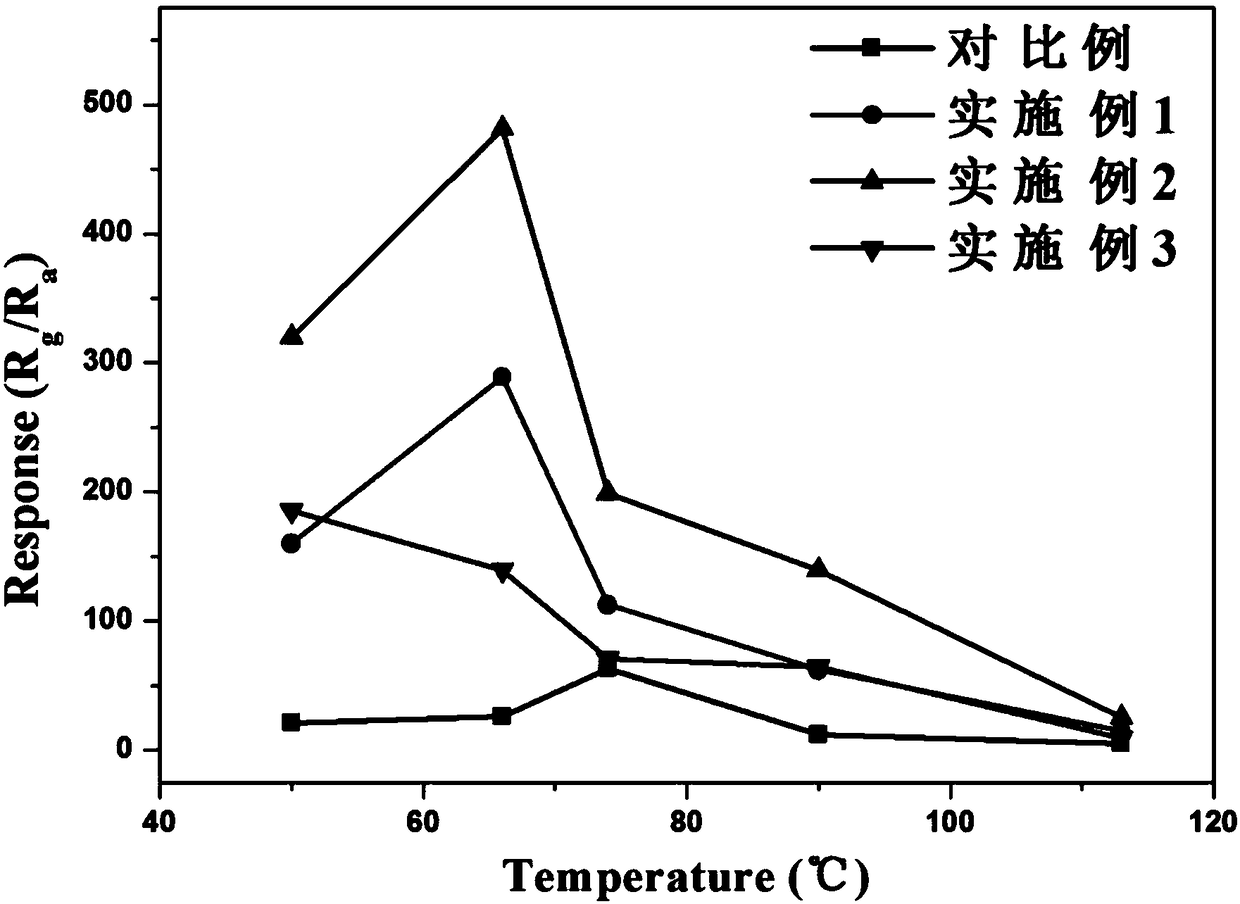

Embodiment 1

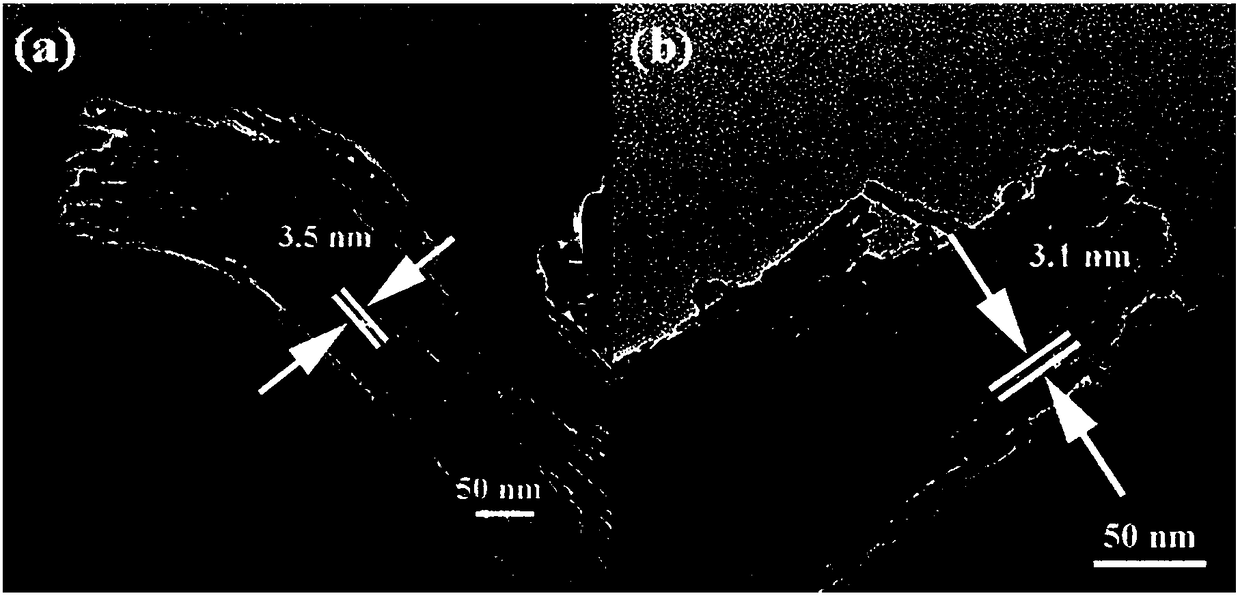

[0036] with Au / In 2 o 3 Au loaded with In at a mass ratio of 0.05:1 2 o 3 Oxide semiconductor as a sensitive material to make NO 2 The sensor, its manufacturing process is:

[0037] 1. First add 1.72g of In(NO 3 ) 3 4.5H 2 O was added to 10 mL of absolute ethanol solution, and kept stirring until it was completely dissolved (stirring time was 60 min);

[0038] 2. Add 0.5g of SBA-15 template to the above solution, react at 40°C until the ethanol evaporates completely, and then calcinate at 300°C for 3 hours to obtain a light yellow powder. The resulting powder was added to 10 mL of absolute ethanol and kept stirring until it was completely dissolved. Add 0.86g of In(NO 3 ) 3 4.5H 2 O, react at 40°C until ethanol evaporates completely, and then calcinate at 500°C for 3 hours. The obtained powder was added to 10 mL of absolute ethanol solution, and kept stirring continuously until it was completely dissolved. Add 0.43g of In(NO 3 ) 3 4.5H 2 O, react at 40°C until ...

Embodiment 2

[0046] with Au / In 2 o 3 Au loaded with In at a mass ratio of 0.10:1 2 o 3 Oxide semiconductor as a sensitive material to make NO 2 sensor, its fabrication process is

[0047] 1. First add 1.72g of In(NO 3 ) 3 4.5H 2 O was added to 10 mL of absolute ethanol solution, and kept stirring until it was completely dissolved (stirring time was 60 min);

[0048]2. Add 0.5g of SBA-15 template to the above solution, react at 40°C until the ethanol evaporates completely, and then calcinate at 300°C for 3 hours to obtain a light yellow powder. The resulting powder was added to 10 mL of absolute ethanol and kept stirring until it was completely dissolved. Add 0.86g of In(NO 3 ) 3 4.5H 2 O, react at 40°C until ethanol evaporates completely, and then calcinate at 500°C for 3 hours. The obtained powder was added to 10 mL of absolute ethanol solution, and kept stirring continuously until it was completely dissolved. Add 0.43g of In(NO 3 ) 3 4.5H 2 O, react at 40°C until the etha...

Embodiment 3

[0056] with Au / In 2 o 3 The mass ratio of Au to In was 0.15:1 2 o 3 Oxide semiconductor as a sensitive material to make NO 2 sensor, its fabrication process is

[0057] 1. First add 1.72g of In(NO 3 ) 3 4.5H 2 O was added to 10 mL of absolute ethanol solution, and kept stirring until it was completely dissolved (stirring time was 60 min);

[0058] 2. Add 0.5g of SBA-15 template to the above solution, react at 40°C until the ethanol evaporates completely, and then calcinate at 300°C for 3 hours to obtain a light yellow powder. The resulting powder was added to 10 mL of absolute ethanol and kept stirring until it was completely dissolved. Add 0.86g of In(NO 3 ) 3 4.5H 2 O, react at 40°C until ethanol evaporates completely, and then calcinate at 500°C for 3 hours. The obtained powder was added to 10 mL of absolute ethanol solution, and kept stirring continuously until it was completely dissolved. Add 0.43g of In(NO 3 ) 3 4.5H 2 O, react at 40°C until the ethanol i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com