Quasi-in-situ experimental method for dynamic shear deformation and failure behavior of metallic material

A technology of shear deformation and experimental method, applied in the direction of analyzing materials, using stable shear force to test material strength, measuring devices, etc., can solve the problem that the shape characteristics of round cap samples cannot be satisfied, and cannot be carried out load again

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A quasi-in-situ experimental method for dynamic shear deformation and failure behavior of pure titanium materials, comprising the following steps:

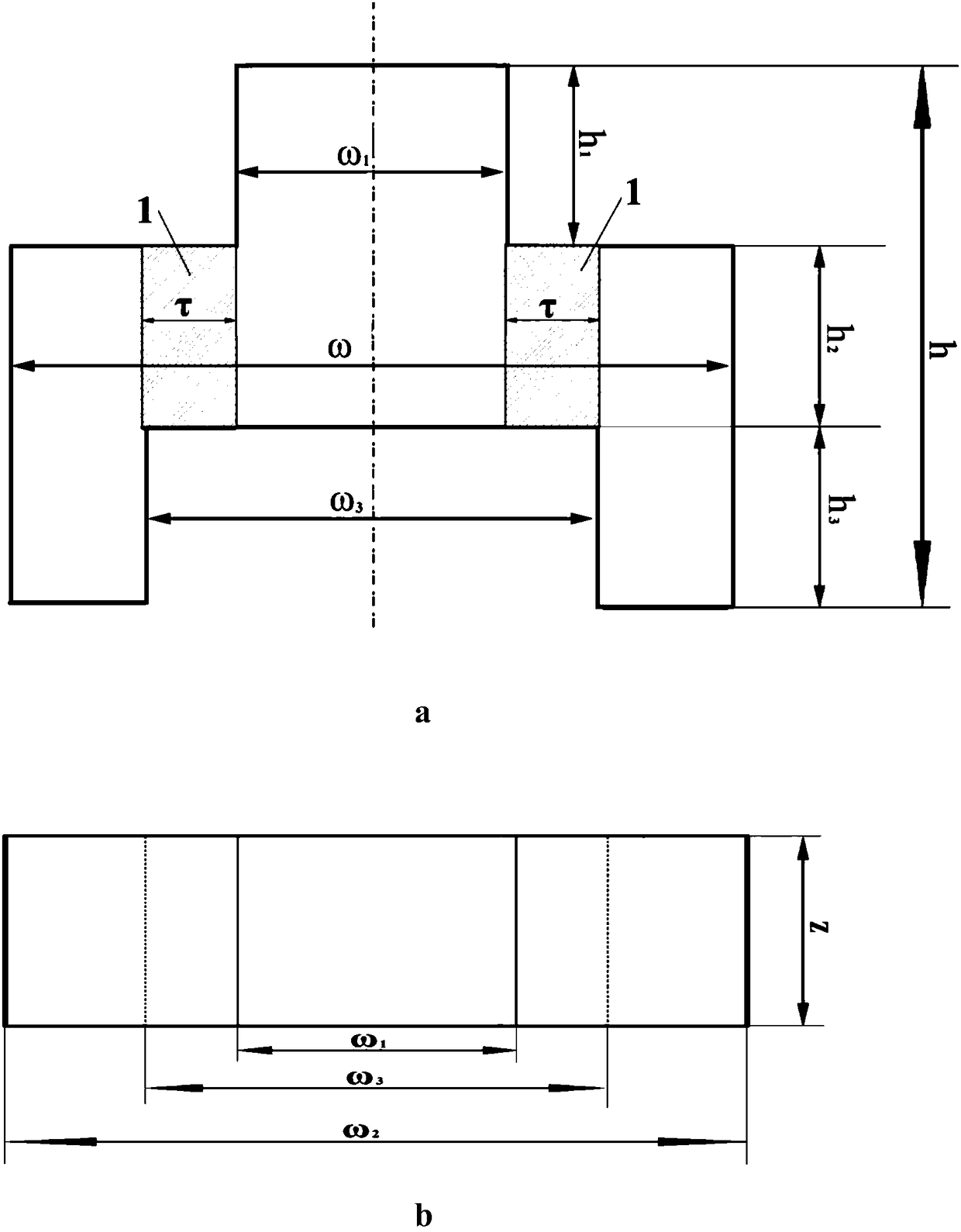

[0027] (1) Prepare the pure titanium material into a square hat-shaped metal sample, the sample thickness z is 3mm, the sample width ω=8mm, the sample height h=9mm; the width of the top convex part ω 1 = 3mm, the height is h 1 =3mm; the width of the bottom concave part ω 3 = 5mm, height h 3 = 3mm; the sample contains two symmetrical shear zones 1, the width τ of the shear zone 1 is 1mm, and the height of the shear zone is h 2 = 3mm; the polished shape is a hat-shaped side, and the shear area on the side is marked, and the scanning electron microscope imaging analysis and electron backscatter diffraction analysis methods are used to observe the tissue morphology and the marked area on the side of the sample before deformation. grain orientation;

[0028] (2) to the sample that step (1) makes in The strain rate is 20000...

Embodiment 2

[0031] A quasi-in-situ experimental method for dynamic shear deformation and failure behavior of aluminum alloy materials, comprising the following steps:

[0032] (1) Prepare the aluminum alloy material into a square hat-shaped metal sample, the overall width of the sample is ω=8mm, the height h=12mm, and the thickness z is 4mm; the width of the raised part of the top of the square hat-shaped sample is ω 1 = 3mm, height h1 =4mm; the width of the bottom concave part ω 3 = 4.5mm, h 3 =4mm; the sample contains two symmetrical shear zones 1, the width τ of the shear zone 1 is 0.75mm, and the height of the shear zone 1 is h 2 = 4mm; the polished shape is a cap-shaped side, mark the shear area on the side, and use scanning electron microscope imaging analysis and electron backscattering diffraction analysis methods to observe the tissue morphology and shape of the marked area on the side of the sample before deformation. grain orientation;

[0033] (2) to the sample that step (1...

Embodiment 3

[0036] A quasi-in-situ experimental method for dynamic shear deformation and failure behavior of pure copper materials, comprising the following steps:

[0037] (1) Prepare pure copper material into a square hat-shaped metal sample, the overall width of the sample is ω=8mm, the height h=9mm, and the thickness z is 3mm; the width of the raised part of the top of the square hat-shaped sample is ω 1 = 4mm, height h 1 =3mm; the width of the bottom concave part ω 3 = 5mm, height h 3 =3mm; the sample contains two symmetrical shear zones 1, the width τ of the shear zone 1 is 0.5mm, and the height of the shear zone is h 2 = 3mm; the polished shape is a hat-shaped side, and the shear area on the side is marked, and the scanning electron microscope imaging analysis and electron backscatter diffraction analysis methods are used to observe the tissue morphology and the marked area on the side of the sample before deformation. grain orientation;

[0038] (2) to the sample that step (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com