Inoculant, feed or additive and removal method for vomitoxin

A technology of vomitoxin and additives, applied in the field of microorganisms, to achieve the effects of removing safety, ensuring safe production, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a preparation method of the above-mentioned inocula, the method comprising: respectively inoculating the above-mentioned yeast and bacillus into the corresponding medium for culturing, and then making the obtained culture into dry powder according to the above ratio After compounding, the bacterial agent of the present invention is obtained.

[0029] In the present invention, the method of inoculating the yeast and bacillus into the culture medium for culturing can be changed in a wide range. For example, the method may include: cultivating the yeast and the bacillus in separate culture systems; and The yeasts and bacilli obtained by culturing separately are made into dry powder and then mixed according to the ratio to obtain the microbial inoculum. The method of making dry powder is well known to those skilled in the art, and will not be repeated here.

[0030] In the second aspect, the present invention provides the application of the a...

Embodiment

[0050] Hereinafter, the present invention will be described in detail through examples, but the present invention is not limited thereby. In the following preparation examples, examples and comparative examples, unless otherwise specified, all materials are commercially available, and all methods are conventional methods in the art.

[0051] YPD medium: 10g yeast extract, 20g peptone, add water to 900ml, sterilize at 115℃ for 20min, then add 100ml of sterilized glucose solution (concentration 20g / 100mL) and mix well.

[0052] LB medium: 5 grams of beef extract, 10 grams of peptone, 5 grams of sodium chloride, add water to 1000 ml, sterilize at 115°C for 20 minutes, pH 7.0-7.2.

[0053] Trichosporon glutinosa CICC 32858, Yarrowia lipolytica CICC 1441, Candida utilis CICC 1314, Brevibacterium casei CICC 23944 were all purchased from the China Industrial Microbial Culture Collection and Management Center.

[0054] Bacillus subtilis BNCC188062 and Bacillus licheniformis BNCC337190 were pu...

preparation example

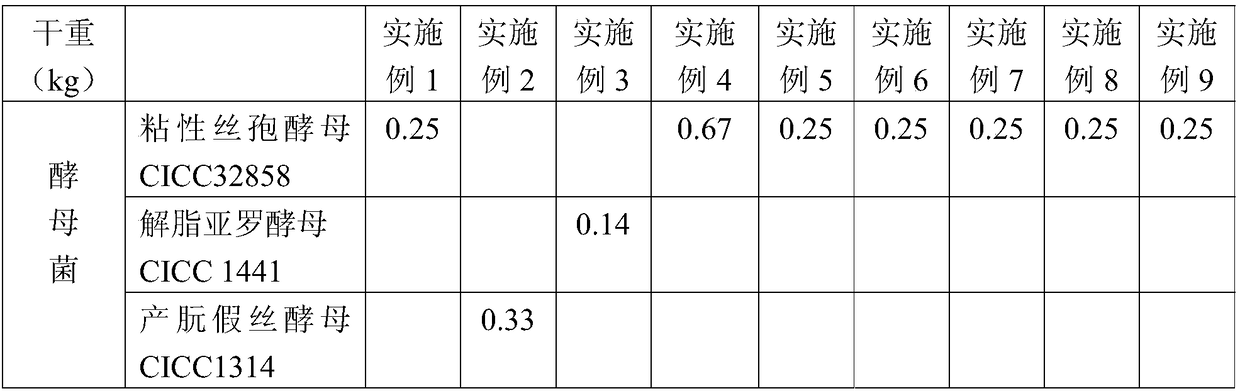

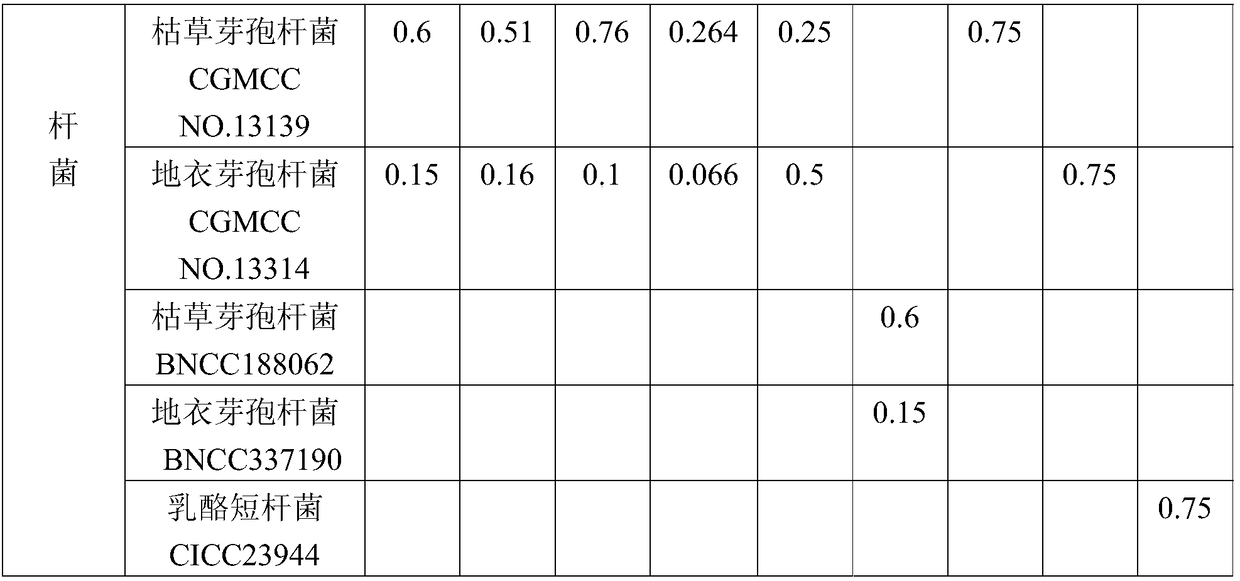

[0056] The activated yeast was inoculated into liquid YPD medium at an inoculum of 1% by volume, and cultured at 150 rpm and 30°C. The culture time was such that the yeast concentration was (1±0.1)×10 9 CFU / ml. The activated bacilli were inoculated into liquid LB medium with an inoculum of 1% by volume, and cultured at 150 rpm and 30°C. The culture time was such that the concentration of bacilli was (1±0.1)×10 9 CFU / ml. Then they are made into dry powders, and the total number of viable bacteria contained in each gram of each dry powder is (1±0.1)×10 9 CFU, and prepare the compound bacterial agent according to the various ratios described in Table 1.

[0057] Table 1

[0058]

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com