Color material for overglaze decoration and preparation method thereof

A technology of overglaze color and color material, which is applied in the field of ceramic manufacturing. It can solve the problems of poor chemical stability, easy-to-dissolve lead and cadmium expansion coefficient, poor gloss, etc., and achieve the effect of pure color, bright and beautiful painted pattern, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

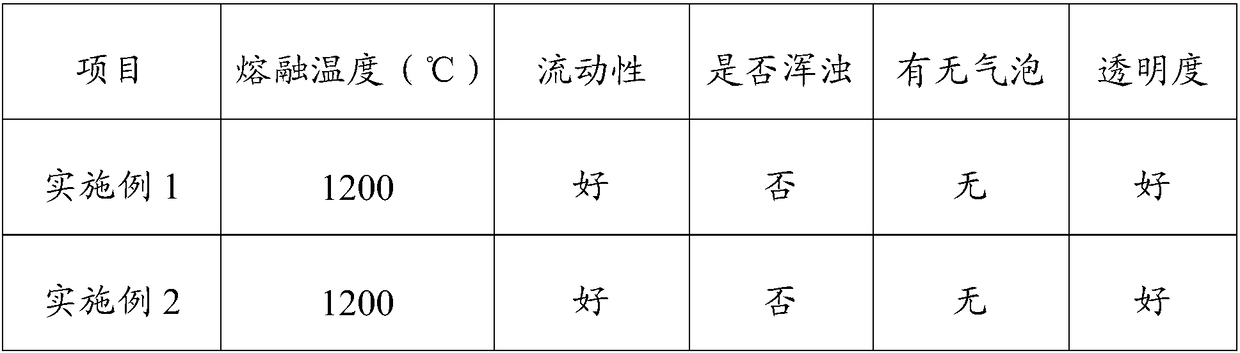

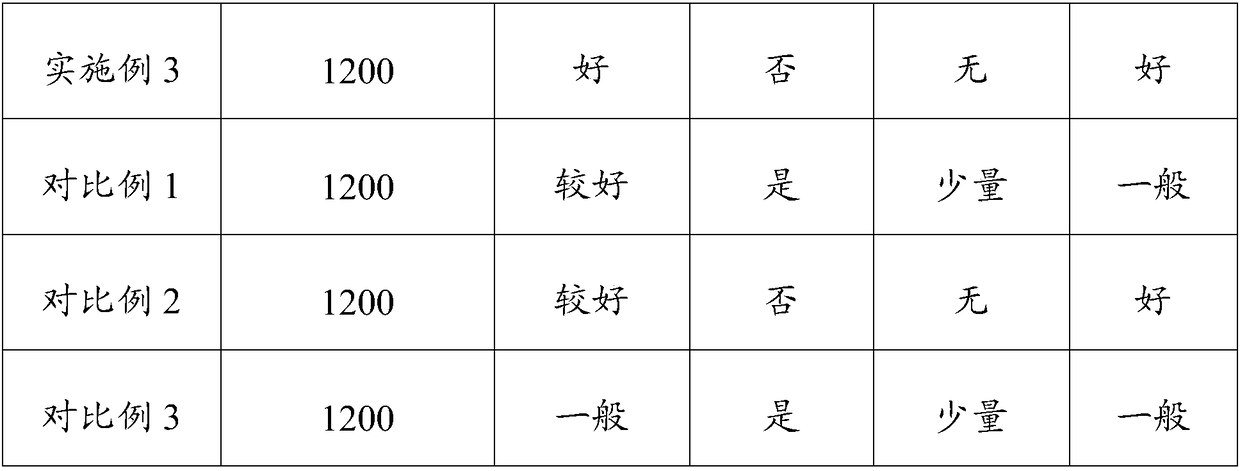

Examples

Embodiment 1

[0030] A color material for overglaze color, the preparation raw material is composed of the following components in parts by weight: 25 parts of manganese red, SiO 2 50 copies, B 2 o 3 10 parts, Al 2 o 3 10 parts, CaO 5 parts, Nb 2 o 5 8 parts, Na 2 O 4 parts, K 2 TiF 6 4 copies, K 2 2 parts of O, 1 part of polyacrylic resin, 8 parts of frankincense oil, 0.5 parts of glass fiber, 1 part of methyl cellulose, and 80 parts of water.

[0031] The specific preparation method is as follows:

[0032] Step 1, take by weight 25 parts of manganese red, SiO 2 50 copies, B 2 o 3 10 parts, Al 2 o 3 10 parts, CaO 5 parts, Nb2 o 5 8 parts, Na 2 O 4 parts, K 2 TiF 6 4 copies, K 2 2 parts of O, 1 part of polyacrylic resin, 8 parts of frankincense oil, 0.5 part of glass fiber, 1 part of methylcellulose, 80 parts of water, for subsequent use;

[0033] Step 2, the SiO taken by weighing in step 1 2 , B 2 o 3 、Al 2 o 3 , CaO, Nb 2 o 5 、Na 2 O, K 2 TiF 6 、K 2 ...

Embodiment 2

[0039] A color material for overglaze color, the preparation raw material is composed of the following components in parts by weight: 30 parts of zirconium iron red, SiO 2 40 copies, B 2 o 3 15 parts, Al 2 o 3 5 parts, CaO 10 parts, Nb 2 o 5 5 parts, Na 2 O 5 parts, K 2 TiF 6 3 copies, K 2 1 part of O, 0.5 parts of polyurethane resin, 10 parts of frankincense oil, 1 part of glass fiber, 0.5 part of methyl cellulose, and 60 parts of water.

[0040] The specific preparation method is as follows:

[0041] Step 1, weigh 30 parts of zirconium iron red, SiO 2 40 copies, B 2 o 3 15 parts, Al 2 o 3 5 parts, CaO 10 parts, Nb 2 o 5 5 parts, Na 2 O 5 parts, K 2 TiF 6 3 copies, K 2 O 1 part, 0.5 part of polyurethane resin, 10 parts of frankincense oil, 1 part of glass fiber, 0.5 part of methyl cellulose, 60 parts of water, for subsequent use;

[0042] Step 2, the SiO taken by weighing in step 1 2 , B 2 o 3 、Al 2 o 3 , CaO, Nb 2 o 5 、Na 2 O, K 2 TiF ...

Embodiment 3

[0048] A color material for overglaze color, the preparation raw material is composed of the following components in parts by weight: 20 parts of cobalt blue, SiO 2 60 copies, B 2 o 3 12 parts, Al 2 o 3 8 parts, CaO 8 parts, Nb 2 o 5 10 parts, Na 2 O 3 parts, K 2 TiF 6 5 copies, K 2 3 parts of O, 0.8 parts of polyacrylic resin, 5 parts of frankincense oil, 0.6 parts of glass fiber, 0.6 parts of methyl cellulose, and 50 parts of water.

[0049] The specific preparation method is as follows:

[0050] Step 1, take by weight 20 parts of cobalt blue, SiO 2 60 copies, B 2 o 3 12 copies, Al 2 o 3 8 parts, CaO 8 parts, Nb 2 o 5 10 parts, Na 2 O 3 parts, K 2 TiF 6 5 copies, K 2 3 parts of O, 0.8 part of polyacrylic resin, 5 parts of frankincense oil, 0.6 part of glass fiber, 0.6 part of methylcellulose, 50 parts of water, standby;

[0051] Step 2, the SiO taken by weighing in step 1 2 , B 2 o 3 、Al 2 o 3 , CaO, Nb 2 o 5 、Na 2 O, K 2 TiF 6 、K 2 O ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com