Compression resistant foaming microcrystal glass plate and preparation method thereof

A glass plate and crystallite technology, which is applied in the field of pressure-resistant foamed glass-ceramic plate and its preparation, can solve the problem of affecting the utilization space and market efficiency of glass-ceramic plate, hindering the development of glass-ceramic industry, reducing the mechanical properties of products, etc. problems, to achieve the effect of low preparation cost, excellent flexural and compressive strength, and strong crystallization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

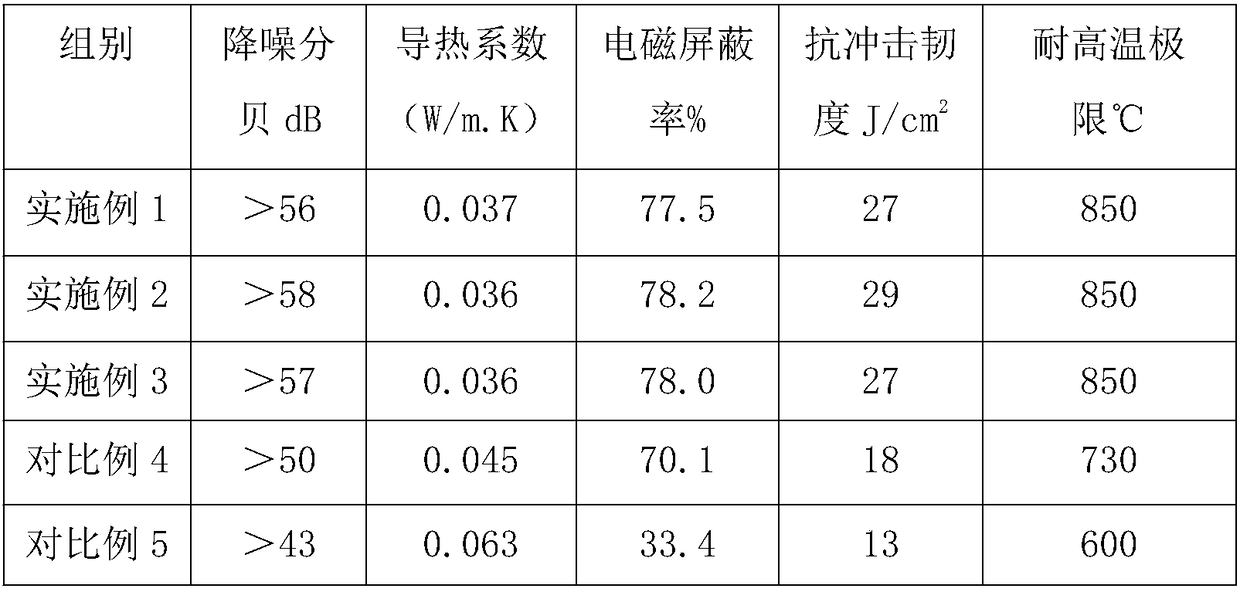

Examples

Embodiment 1

[0026] A kind of pressure-resistant foamed glass-ceramic plate, obtain the following raw materials: 250kg of siderite, 500kg of vein quartz, 200kg of limestone, 100kg of floating pearl powder, 80kg of burnt gemstone, 40kg of andalusite, 100kg of cordierite, 10kg of titanium tetrachloride, Zirconium silicate 10kg, sodium carbonate 30kg and composite metal oxide 150kg.

[0027] The composite metal oxide is obtained by mixing 40kg of zirconium dioxide, 30kg of bismuth trioxide, 30kg of manganese oxide, 30kg of tin dioxide and 20kg of praseodymium oxide.

[0028] The preparation method of the above-mentioned pressure-resistant foamed glass-ceramic plate is carried out according to the following steps:

[0029] (1) First crush and ball-mill the above-mentioned weighed bulk raw materials to a particle size of 15mm, and carry out magnetic separation to siderite, vein quartz, limestone, burnt gemstone, andalusite and cordierite to remove impurities;

[0030] (2) Use a hydrochloric ac...

Embodiment 2

[0036] A kind of pressure-resistant foamed glass-ceramic plate, obtain following raw materials: 300kg of siderite, 550kg of vein quartz, 250kg of limestone, 150kg of floating pearl powder, 100kg of burnt gemstone, 60kg of andalusite, 120kg of cordierite, 12kg of titanium tetrachloride, Zirconium silicate 15kg, sodium carbonate 40kg and composite metal oxide 200kg.

[0037] The composite metal oxide is obtained by mixing 40kg of lanthanum trioxide, 40kg of zirconia, 40kg of vanadium pentoxide, 40kg of boron oxide, 20kg of scandium oxide and 20kg of yttrium oxide.

[0038] The preparation method of the above-mentioned pressure-resistant foamed glass-ceramic plate is carried out according to the following steps:

[0039] (1) First crush and ball-mill the above-mentioned weighed bulk raw materials to a particle size of 10 mm, and carry out magnetic separation to remove impurities from siderite, vein quartz, limestone, coke gemstones, andalusite and cordierite;

[0040] (2) Use a ...

Embodiment 3

[0046] A kind of pressure-resistant foamed glass-ceramic plate, obtain following raw materials: 350kg of siderite, 600kg of vein quartz, 300kg of limestone, 200kg of floating pearl powder, 120kg of burnt gemstone, 80kg of andalusite, 150kg of cordierite, 15kg of titanium tetrachloride, Zirconium silicate 20kg, sodium carbonate 50kg and composite metal oxide 250kg.

[0047] The composite metal oxide is obtained by mixing 80kg of zirconium dioxide, 40kg of bismuth trioxide, 60kg of boron oxide, 40kg of tantalum pentoxide and 30kg of praseodymium oxide.

[0048] The preparation method of the above-mentioned pressure-resistant foamed glass-ceramic plate is carried out according to the following steps:

[0049] (1) First crush and ball-mill the above-mentioned weighed bulk raw materials to a particle size of 15mm, and carry out magnetic separation to siderite, vein quartz, limestone, burnt gemstone, andalusite and cordierite to remove impurities;

[0050] (2) Use a hydrochloric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com