A method for magnetic seed regeneration

A magnetic seed and demagnetization technology, applied in chemical instruments and methods, magnetic field/electric field water/sewage treatment, water/sludge/sewage treatment, etc. Achieve the effect of increasing dispersion, increasing contact surface and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

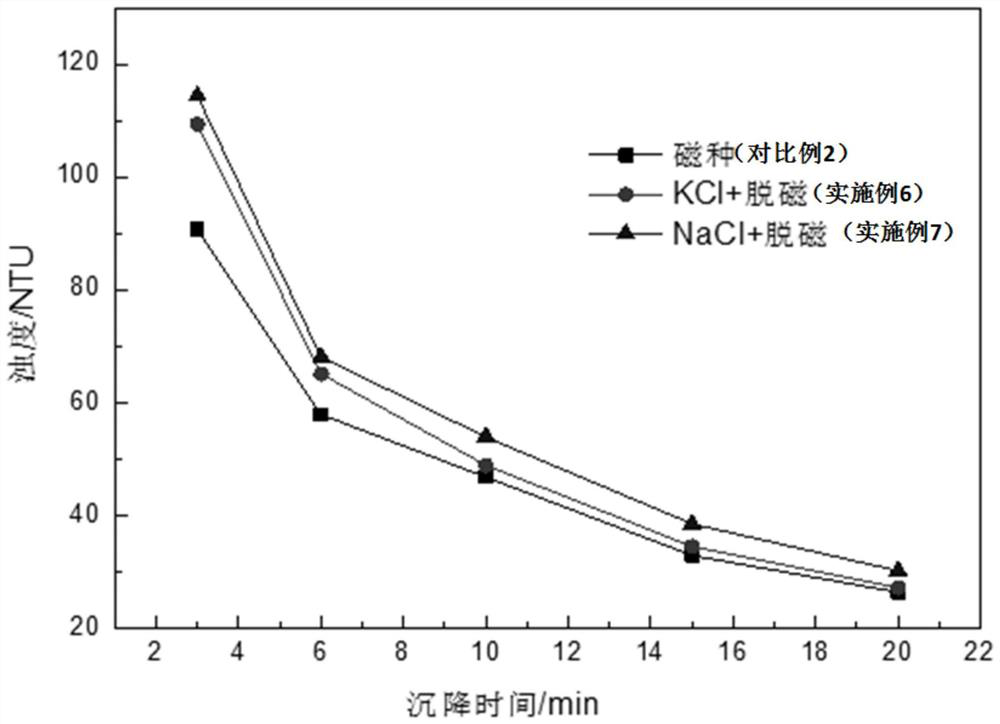

Examples

Embodiment 1

[0017] Magnetic flocculation wastewater clarification: the raw material of wastewater is iron tailings wastewater, the -15μm particle size accounts for 99%, and the weight concentration of ore slime is 2%. Add magnetic seeds to the waste water until its weight concentration is 0.2% (average particle size is 22.46 μm), and add medicament anionic polyacrylamide (APAM) to its concentration of 1.2mg / L, settle after stirring and flocculating to obtain magnetic Kind of slime.

[0018] Magnetic seed recovery and regeneration: introduce the magnetic seed-containing slime obtained by sedimentation into the magnetic separation equipment to recover the magnetic seed suspension solution, and then introduce the magnetic seed suspension solution into the demagnetizer for demagnetization treatment 1.5 min (the magnetic field strength is 200G), to obtain the magnetic seed suspension solution after demagnetization (the mass concentration of the magnetic seed is 30%). Then the magnetic seed so...

Embodiment 2

[0021] It is the iron chloride of 20mg / L that the ferrous chloride that the concentration in embodiment 1 is changed into concentration is 20mg / L, other conditions are constant. The results of the obtained regenerated magnetic seeds for iron tailings wastewater treatment are shown in Table 1.

Embodiment 3

[0023] Concentration in embodiment 1 is that the ferrous chloride of 20mg / L is changed into the magnesium chloride that concentration is 100mg / L, other conditions are constant. The results of the obtained regenerated magnetic seeds for iron tailings wastewater treatment are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com