Preparation method and application of a rod-shaped zinc oxide gas-sensitive material

A gas-sensitive material, zinc oxide technology, applied in zinc oxide/zinc hydroxide, material resistance, analytical materials, etc., can solve the problems of cumbersome operation, time-consuming, unfavorable real-time monitoring by regulatory authorities, etc., to achieve simple and time-consuming operation. short, the effect of preventing illegal drugs from entering the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

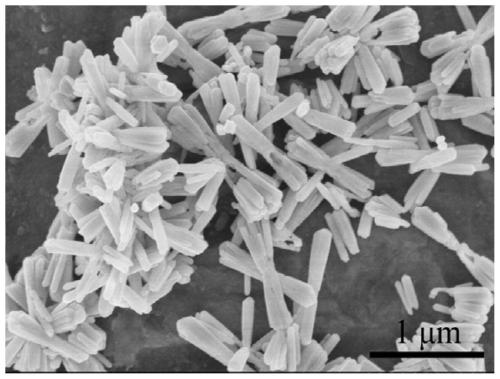

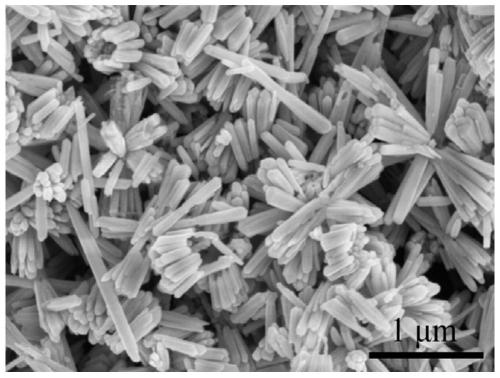

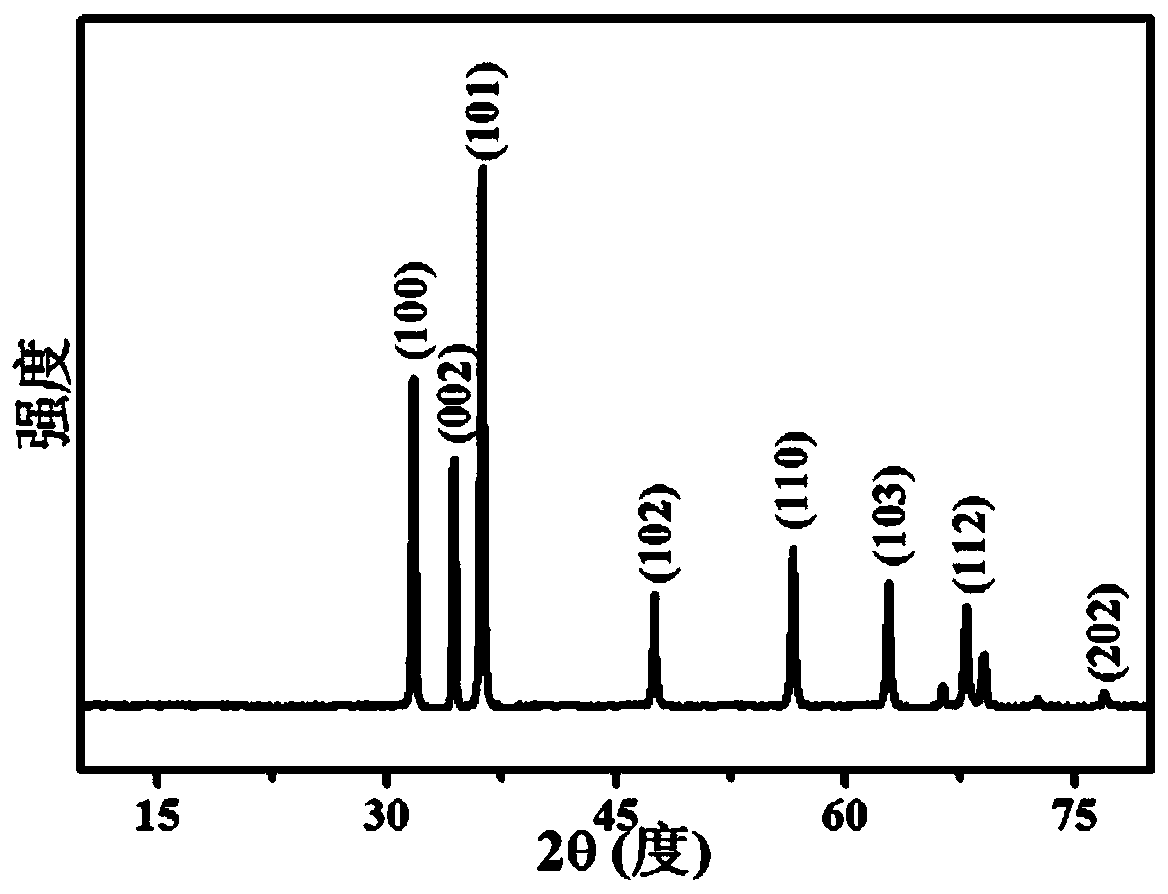

[0025] Specific embodiment one: the preparation method of a kind of rod-shaped zinc oxide gas-sensitive material in this embodiment is carried out according to the following steps:

[0026] 1. After mixing urea and zinc acetylacetonate in a molar ratio of 2 to 6:1, dissolve it in a mixed solvent with a volume ratio of water and methanol of 1 to 10:1, so that the concentration of zinc acetylacetonate solution is 0.01 to 0.12 mol / L, magnetic stirring to obtain a clear solution, transfer the solution to a hydrothermal reaction kettle, and react at 120-220°C for 2-20 hours to obtain a white precursor;

[0027] 2. Centrifuge the precursor obtained in step 1, wash it with deionized water and absolute ethanol respectively, dry it at 60-120°C for 6-24h, and then heat-treat it in air at 500-600°C for 2-4h , to obtain white ZnO nanorod bundle powder.

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 1, urea and zinc acetylacetonate are mixed in a molar ratio of 3:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume ratio of water and methanol in the mixed solvent described in step 1 is 5:1. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com