Deep-sea automatic continuous sectional intelligent buoyage system

A self-sustaining, buoy technology, used in buoys, special-purpose ships, ships, etc., can solve problems such as low service life, affecting the working efficiency of the internal oil bag oil discharge capacity system, and improving the production cost of buoy prototypes, achieving low power consumption. , Simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

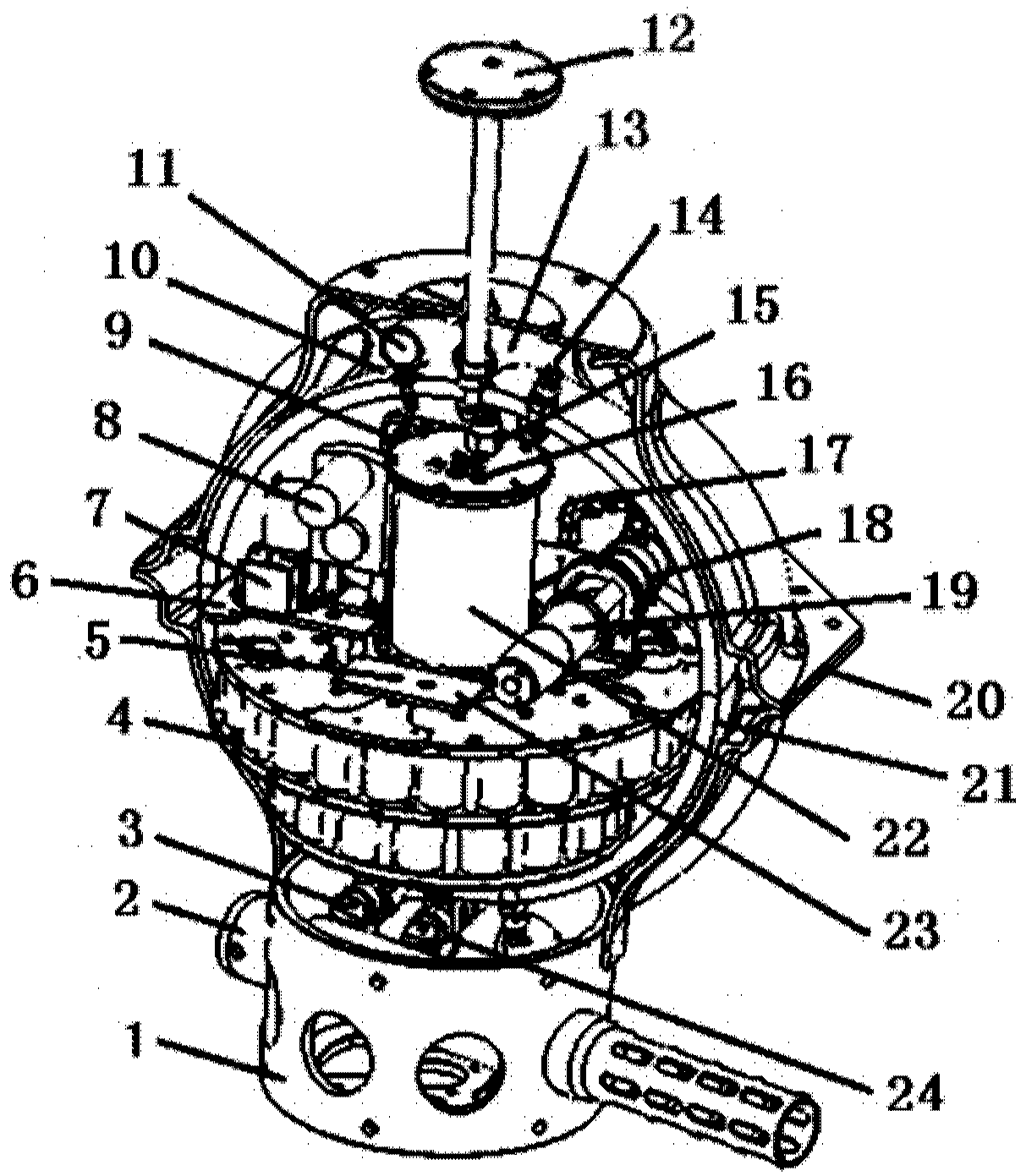

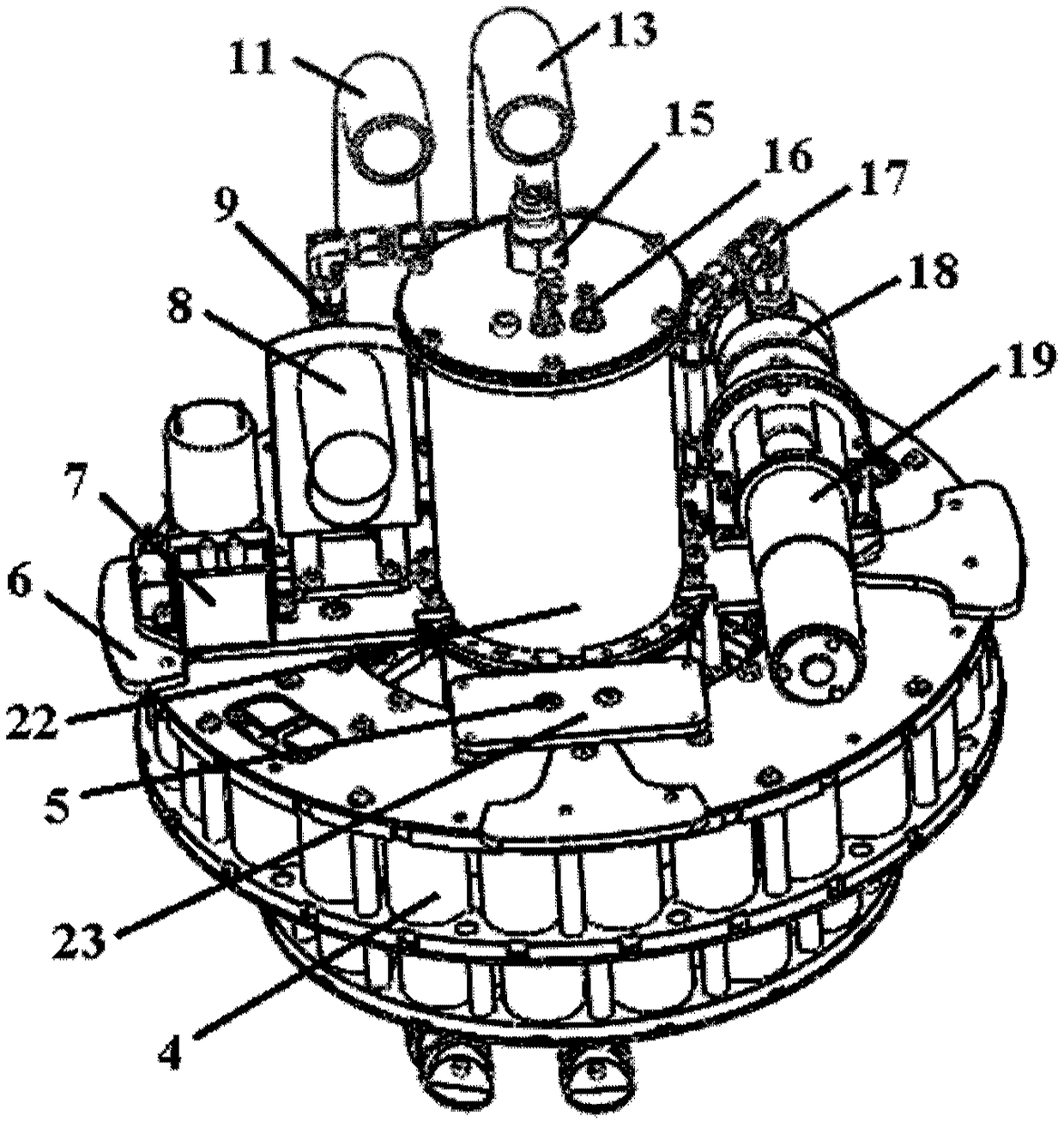

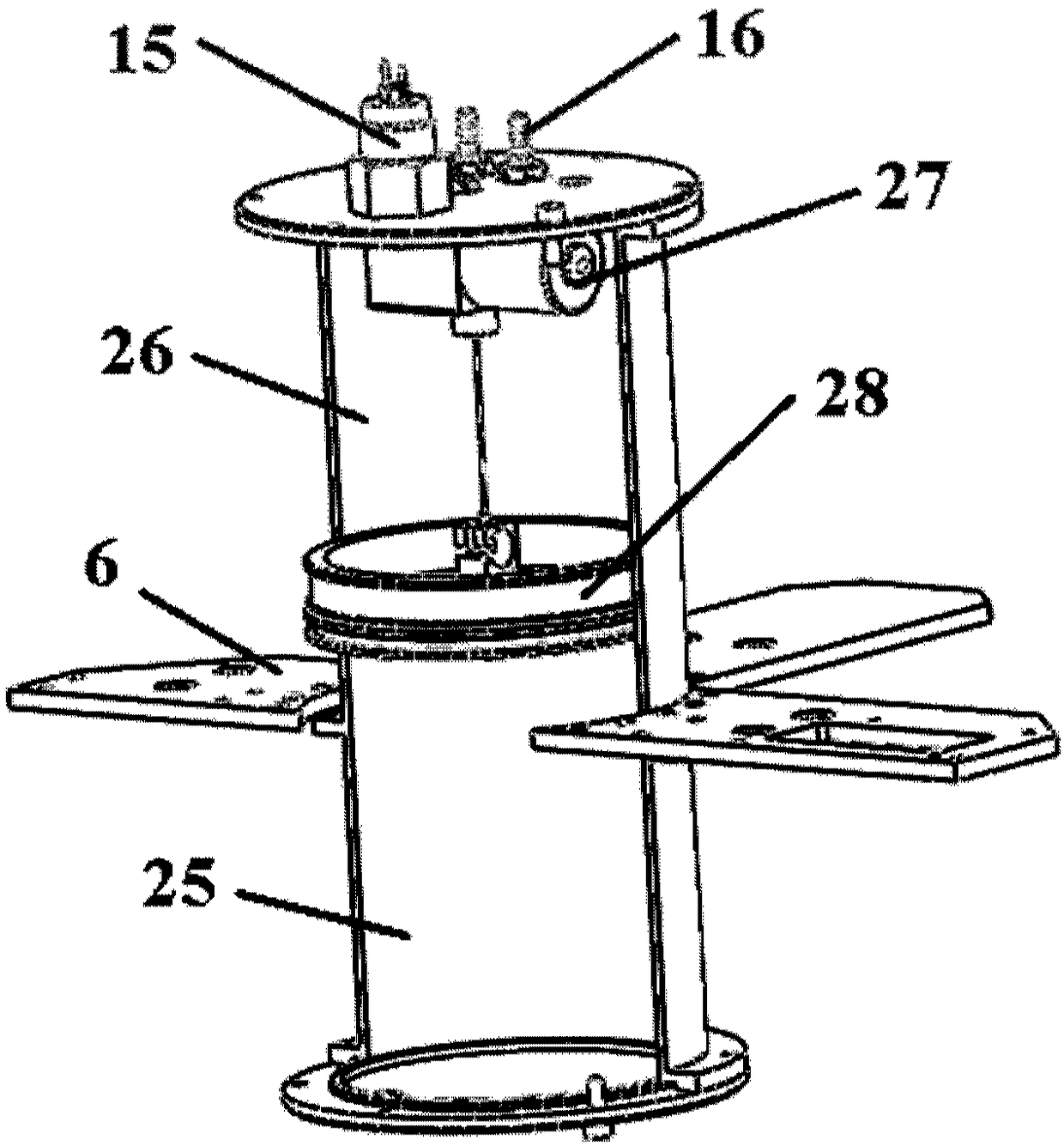

[0030] The present disclosure provides a deep-sea self-sustained profile intelligent buoy system, which is used to measure hydrological data such as temperature, salinity, and depth in a full-depth profile of the ocean from 0 to 6000 meters. The overall structure of the buoy system involved in the present disclosure is mainly composed of a satellite communication system, a buoy protection cover, a glass float pressure cabin, a hydraulic system component, a pneumatic system component, a battery pack, a circuit control system, a temperature and salt depth sensor, and a buoy lower base. . The hydraulic system components include a high-pressure plunger pump, an internal oil bag, a one-way valve and a ball valve. Pneumatic system components include air pump and solenoid valve. A piston is arranged in the inner oil bag, and the inner cavity is divided into an inner oil cavity and an inner air cavity. The high-pressure plunger pump is driven by a DC motor. Pumping the hydraulic oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com