A load-sensitive forklift multi-way valve

A load-sensitive, multi-way valve technology, used in lifting devices, fluid pressure actuating devices, servo motor components, etc., can solve the problems of reducing the service life of hydraulic systems, waste of energy consumption, and high prices, reducing load and reducing The effect of energy consumption and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

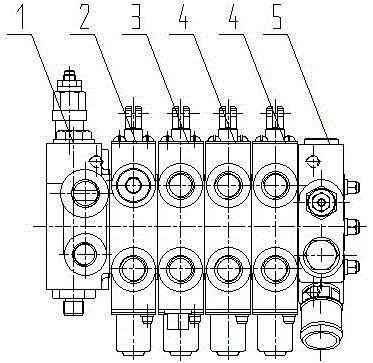

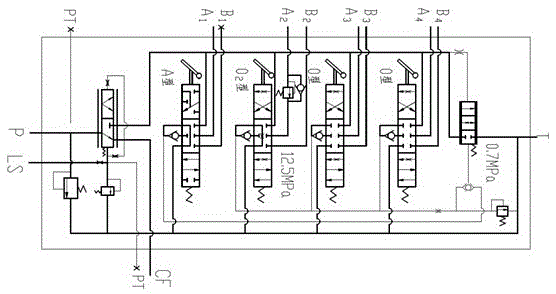

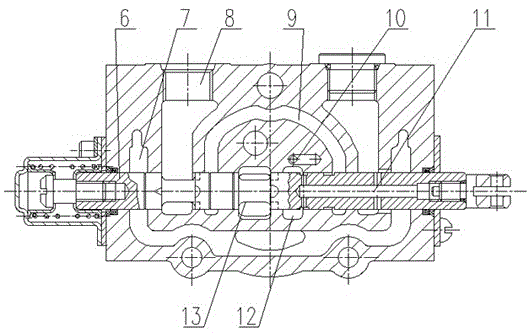

[0026] Such as figure 1 As shown, a forklift multi-way valve with a load-sensitive function applied to a quantitative system according to the present invention includes an oil inlet valve section 1, an oil return valve section 5, a lift valve section 2, a tilt valve section 3 and a The attachment valve plate 4 for controlling other actions, the structure of the oil inlet valve plate of the present invention is the prior art, and there are corresponding records in ZL201320144216.6. The lifting valve plate 2, the tilting valve plate 3 and the attachment valve plate 4 include a valve body and an oil passage, and a flow control valve stem and an oil inlet check valve that can control the flow of each working mechanism are respectively arranged in the valve body; The tilt valve plate 3 is provided with a load holding valve 14 to stabilize the forward pressure and reduce the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com