Device and method for diamond micro-powder overflowing grading treatment

A diamond micropowder and grading treatment technology, which is applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of low production efficiency, large amount of pure water, wide particle size distribution of sedimentation and grading, and achieve fine powder particle size concentration, The effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

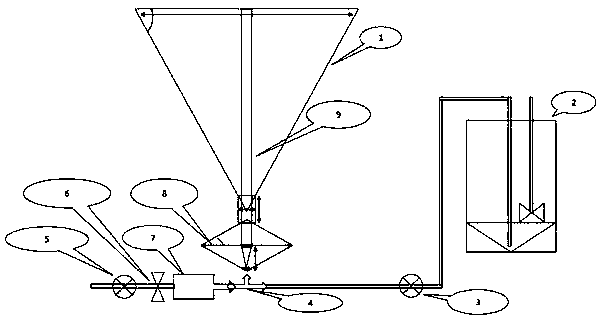

[0021] Such as figure 1 As shown, a kind of diamond powder overflow classification treatment equipment, including feed pump, metering pump, flow divider, guide column and overflow cone, homogenization tank, pure water device, one end of feed pump and homogenization tank One end of the metering pump is connected to the pure water device, the other end is connected to the one-way valve, the diversion column runs through the liquid separator and the overflow cone, and the bottom end of the diversion column is connected to the one-way valve. Catchy connection. The mechanical metering pump can accurately control the flow of pure water entering the overflow cone, so as to ensure that the drag force of the diamond particles when the water rises during the overflow process is controllable; there is a butterfly-shaped liquid separation at the bottom of the overflow cone Pure water enters the butterfly separator and disperses, and then spreads smoothly upward along the diversion column...

Embodiment 2

[0032] The difference from Example 1 is that the production of 6-12um particle size is taken as an example. The operation is as follows: put 10,000ct of diamond powder with mixed particle size into the classification operation, control the flow rate of 0.22m3 / h and the pressure of 0.3Mpa to overflow for 18h, and first put the 5- 10um and finer particles are separated, and then the influent flow is increased for overflow classification for 12 hours to obtain 1,000ct (the output has a great relationship with the particle size distribution of the feed) 6-12um.

[0033] D10

[0034] The particle size test results of the product are shown in the table above.

Embodiment 3

[0036] Taking the production of 7-14um particle size as an example, the operation is as follows: put 10,000ct mixed particle size diamond powder into the classification operation, control the flow rate of 0.5m3 / h and the pressure of 0.4Mpa to overflow for 12h, first classify the 6-12um and finer particles Then increase the influent flow and overflow classification for 12 hours to obtain 1,000ct (the output has a great relationship with the particle size distribution of the feed) 7-14um.

[0037] D10

[0038] The particle size test results of the product are shown in the table above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com