Polycarboxylate-type water reducing agent as well as preparation method and application thereof

A technology of polycarboxylic acid series and water reducing agent, applied in the field of building materials, can solve the problems of high gas content and high reaction temperature of early strength polycarboxylic acid series water reducing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

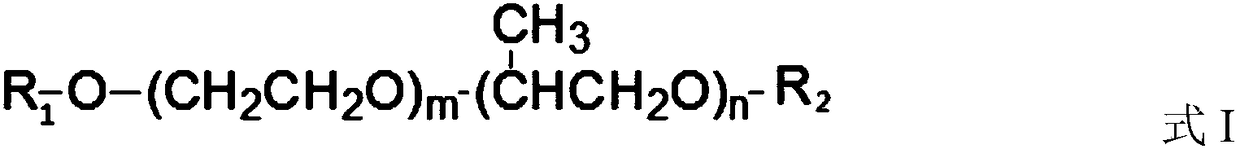

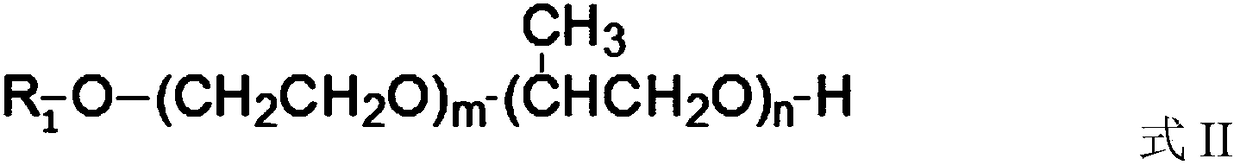

Method used

Image

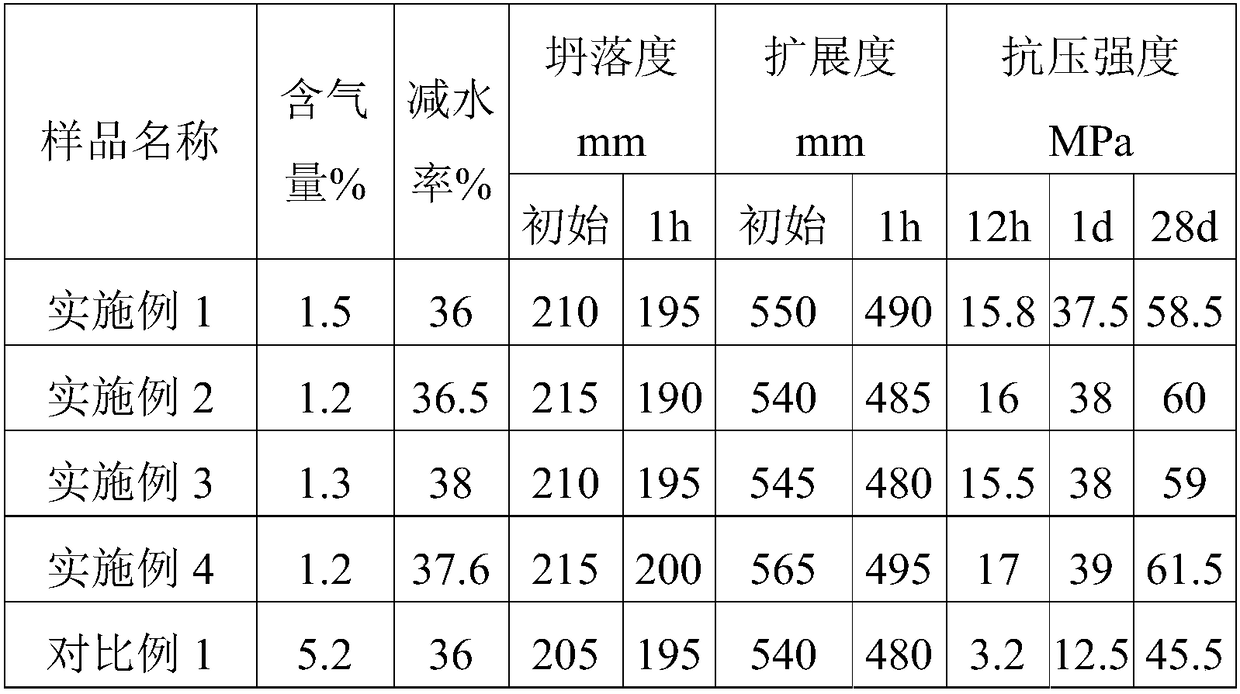

Examples

Embodiment 1

[0067] (1) Under the stirring state, pre-drop the reducing agent solution into the mixture A for 10 minutes, and then drop the mixture B at the same time; when the dropping time of the mixture B is halfway, add the remaining 0.4 parts of the initiator (persulfuric acid Ammonium);

[0068] Among them, mixture A is prepared by the following steps: add 100 parts of polyether monomer A with a number average molecular weight of 4000 and 100 parts of water into the reaction kettle, and stir evenly; when the temperature of the system reaches 5°C, add 0.4 parts of initiator (ammonium persulfate), initiate reaction, mix to obtain mixture A;

[0069] Mixture B is made by uniformly mixing 12 parts of monomer B (acrylic acid), 4 parts of monomer C (acrylamide), 0.8 parts of chain transfer agent (mercaptoethanol) and 30 parts of water; the dropping time of mixture B is 2h; B is added dropwise at a uniform speed;

[0070] The reducing agent solution is mixed with 0.2 parts of reducing age...

Embodiment 2

[0078] (1) In the stirring state, pre-drop the reducing agent solution to the mixture A for 15 minutes, and then drop the mixture B at the same time; when the addition time of the mixture B is halfway, add the remaining 0.6 parts of the initiator (peroxide hydrogen);

[0079] Wherein, the mixture A is prepared through the following steps: adding 100 parts of polyether monomer A, 4 parts of monomer B (methacrylic acid) and 80 parts of water into the reactor with a number average molecular weight of 6000, and stirring evenly; When the temperature of the system reaches 10°C, add 1.4 parts of initiator (hydrogen peroxide) to initiate the reaction, and mix uniformly to obtain mixture A;

[0080] Mixture B is made by uniformly mixing 16 parts of monomer B (methacrylic acid), 8 parts of monomer C (N-methylolacrylamide), 2 parts of chain transfer agent (mercaptopropionic acid) and 20 parts of water; mixture B The dropping time of the mixture is 4 hours; the dropping speed of the mixt...

Embodiment 3

[0089] (1) In the state of stirring, pre-drop the reducing agent solution into the mixture A for 5 minutes, and then drop the mixture B at the same time; when the dropping time of the mixture B is halfway, add the remaining 0.2 parts of the initiator (persulfuric acid Ammonium);

[0090] Wherein, the mixture A is prepared by the following steps: 100 parts of polyether monomer A with a number average molecular weight of 8000, 1 part of monomer B (acrylic acid) and 43 parts of water are added to the reactor and stirred evenly; when the system temperature When it reaches 30°C, add 0.4 parts of initiator (ammonium persulfate) to initiate the reaction, and mix well to obtain mixture A;

[0091] Mixture B is prepared by uniformly mixing 9 parts of monomer B (acrylic acid), 3 parts of monomer C (2-acrylamide-2-methylpropanesulfonic acid), 0.6 parts of chain transfer agent (thioglycolic acid) and 40 parts of water; The dropping time of the mixture B is 3h; the dropping speed of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com