Organic synthesis raw material valeric acid synthesis method

A technology of organic synthesis and synthesis method, which is applied in the field of synthesis of valeric acid, a raw material for organic synthesis, can solve problems such as low yield and complicated process, and achieve the effects of shortening reaction time, reducing intermediate links, and improving reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

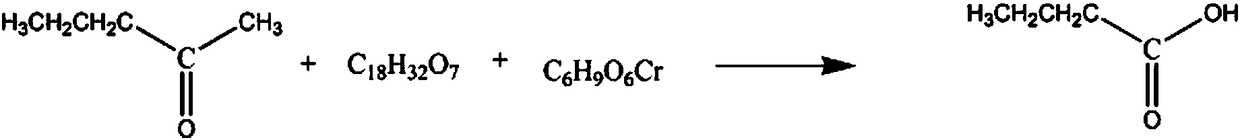

Method used

Image

Examples

example 1

[0010] Add 3mol of methyl propyl ketone and 4mol of tributyl citrate solution with a mass fraction of 70% in the reaction vessel, control the stirring speed at 190rpm, lower the solution temperature to 6°C, keep it for 60min, and then increase the solution temperature to 10°C , add 3 mol of chromium acetate in 3 times, each interval of 30min, continue to react for 2h, then let it stand for 60min, add 300ml of potassium nitrate solution with a mass fraction of 20%, the solution is layered, and the water layer is 70% with a mass fraction of The 4-heptanone solution was extracted 3 times, the mass fraction was 80% 3-methyl-2-pentanone solution extracted 4 times, the oil layer and the extract were combined, and the mass fraction was 90% isobutyl butyrate solution. Crystallized and dehydrated with anhydrous magnesium sulfate dehydrating agent to obtain 240.24 g of finished valeric acid with a yield of 91%.

example 2

[0012] Add 3mol of methyl propyl ketone and 5mol of tributyl citrate solution with a mass fraction of 75% in the reaction vessel, control the stirring speed to 210rpm, lower the solution temperature to 7°C, keep it for 70min, and then increase the solution temperature to 12°C , add 3.5mol of chromium acetate in 5 times, each time interval is 35min, continue to react for 2.5h, then let it stand for 70min, add 300ml of potassium nitrate solution with a mass fraction of 23%, the solution is layered, and the water layer uses a mass fraction of 72% % 4-heptanone solution was extracted 4 times, the mass fraction was 85% 3-methyl-2-pentanone solution was extracted 5 times, the oil layer and the extract were combined, and the mass fraction was 93% isobutyl butyrate solution Medium recrystallization, dehydration with anhydrous potassium carbonate dehydrating agent, 245.52 g of finished valeric acid was obtained, yield 93%.

example 3

[0014] Add 3mol of methyl propyl ketone and 6mol of tributyl citrate solution with a mass fraction of 78% in the reaction vessel, control the stirring speed at 220rpm, lower the solution temperature to 9°C, keep it for 80min, then increase the solution temperature to 15°C , add 4mol of chromium acetate in 6 times, each interval of 40min, continue to react for 3h, then let it stand for 80min, add 300ml of potassium nitrate solution with a mass fraction of 26%, the solution is layered, and the water layer is 75% with a mass fraction of The 4-heptanone solution was extracted 5 times, the mass fraction was 88% 3-methyl-2-pentanone solution was extracted 6 times, the oil layer and the extract were combined, and the mass fraction was 96% in isobutyl butyrate solution. Crystallized and dehydrated with anhydrous magnesium sulfate dehydrating agent to obtain 253.44 g of finished valeric acid with a yield of 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com