Curved pipe press-fitting welding auxiliary device and curved pipe press-fitting welding method

A technology for auxiliary devices and arc-shaped tubes, applied in auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve problems such as high assembly technology requirements, product quality decline, and affecting production efficiency, and achieve high cost performance and assembly accuracy High, large output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

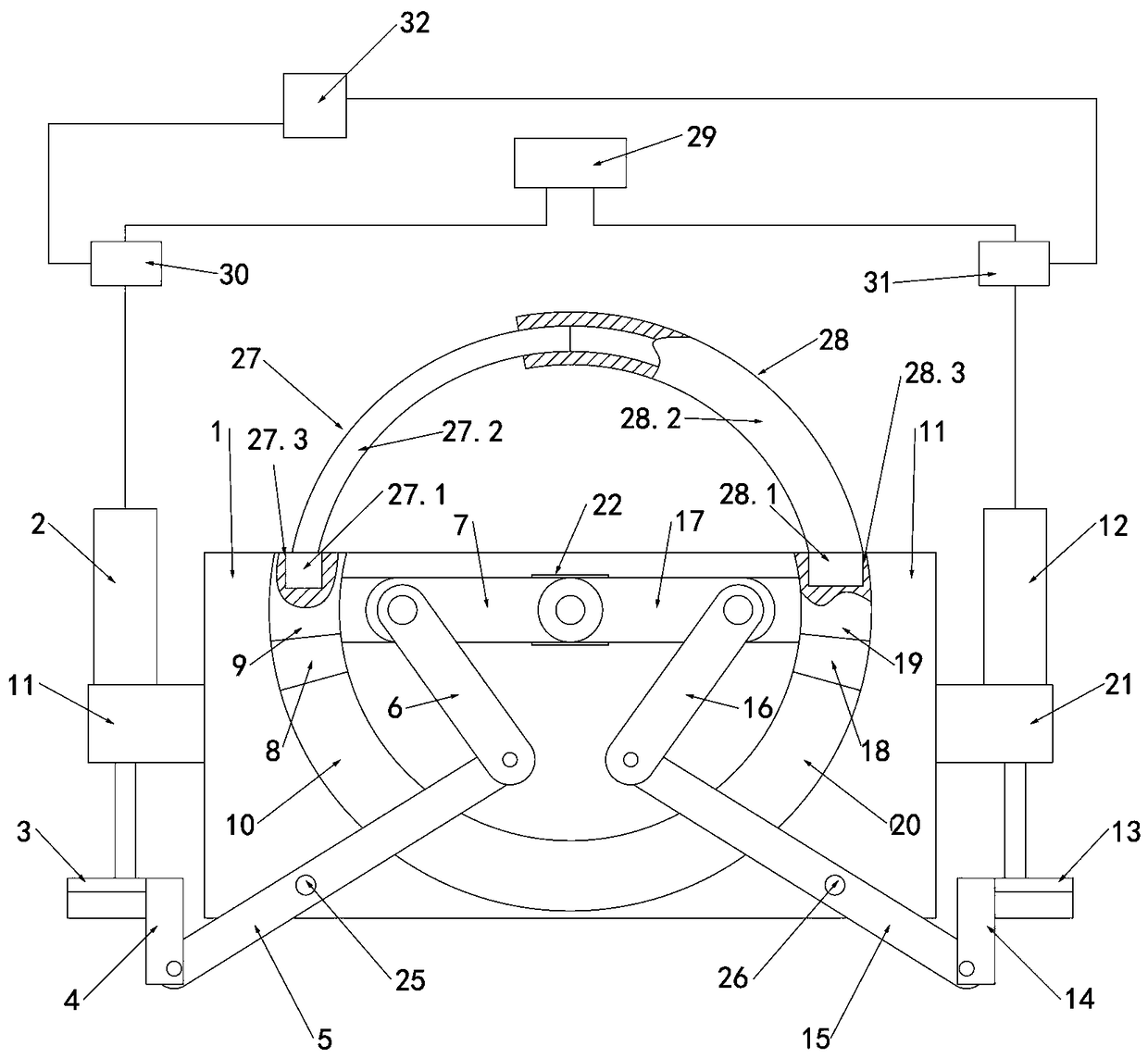

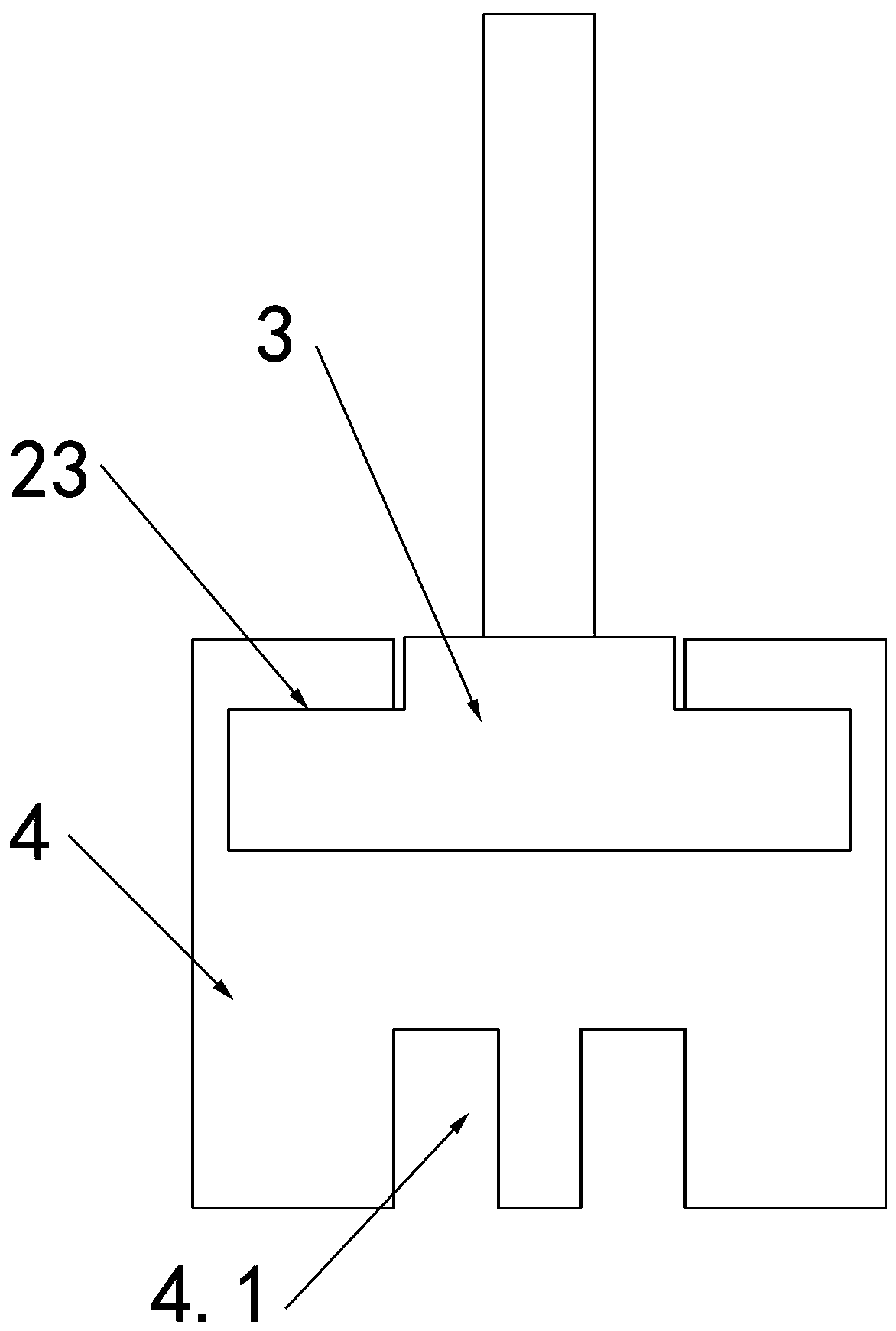

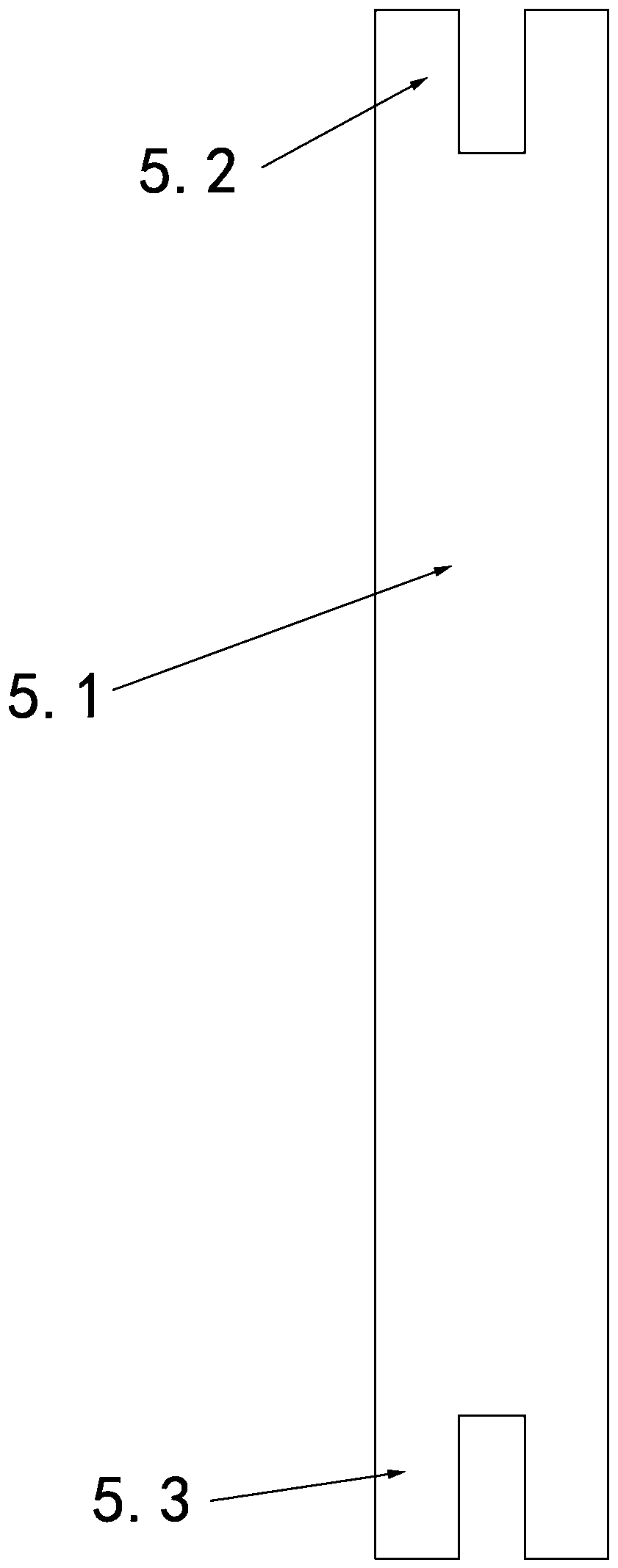

[0030]As shown in 1-5, the arc-shaped tube press-fit welding auxiliary device includes an arc-shaped tube auxiliary fixing device mounting plate 1, a left arc-shaped tube auxiliary fixing device, a right arc-shaped tube auxiliary fixing device and a swing rod mounting seat 22 , the left arc tube auxiliary fixing device and the right arc tube auxiliary fixing device are symmetrically installed on the left and right sides of the arc tube auxiliary fixing device mounting plate 1, and the swing rod mounting seat 22 is installed on the arc tube auxiliary fixing device mounting plate 1 The upper middle section of the front side, the left arc-shaped pipe auxiliary fixing device includes a left slide rail push-pull mechanism 2, a left slide rail 3, a left slide rail structure 4, a left warping rod 5, a left connecting rod 6, a left swing rod 7, a left Arc slider 8, left mounting block 9, left arc chute 10 and left slide rail push-pull mechanism mount 11, left slide rail push-pull mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com