High-precision waveguide power divider and processing method thereof

A processing method and power divider technology, which are applied to waveguide-type devices, electrical components, connecting devices, etc., can solve the problems of difficulty in guaranteeing the dimensional accuracy of the waveguide and the surface roughness of the inner cavity, the randomness of deformation, and the large welding deformation. , to achieve excellent mechanical properties and corrosion resistance, improve dimensional accuracy and surface roughness, and reduce the effects of production and processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

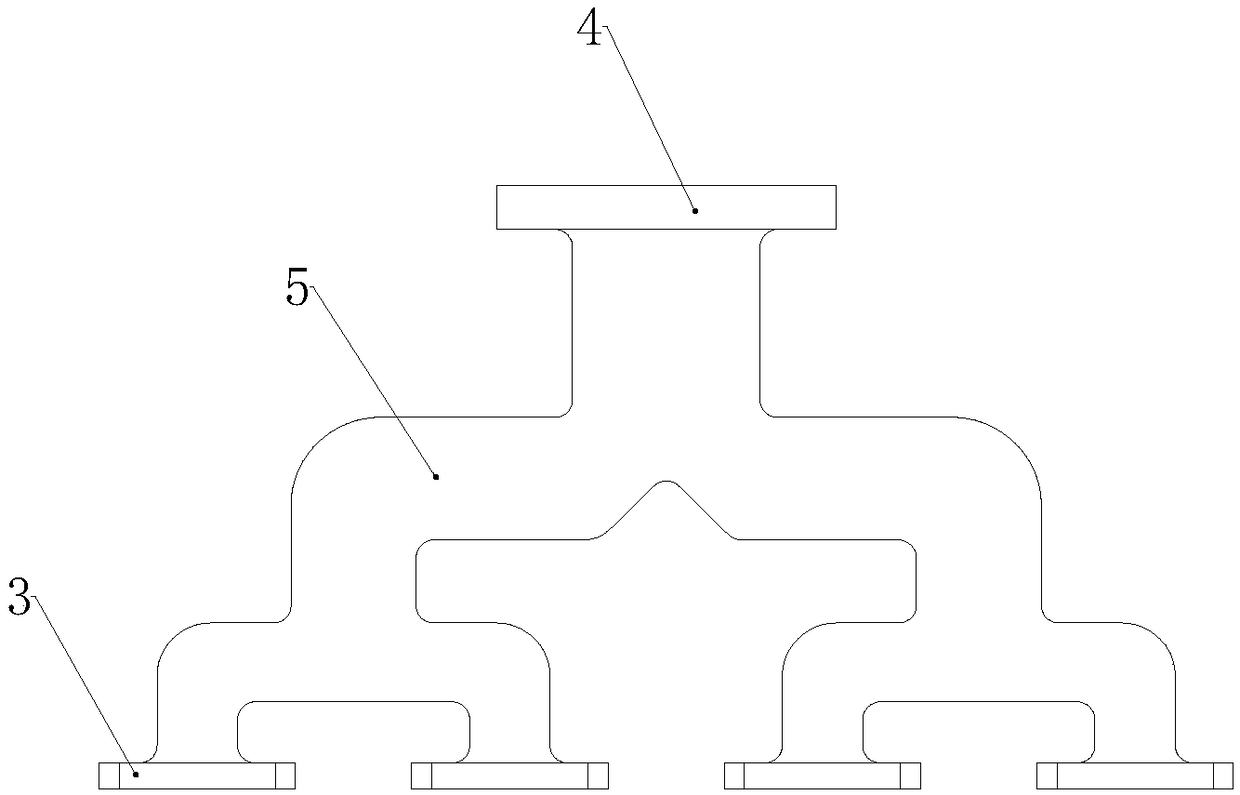

[0037] Such as figure 1 , 2 As shown, the one-to-four high-precision waveguide power divider is made of 3A21 anti-rust aluminum alloy to prepare the upper cavity 1 and the lower cavity 2, and then the upper cavity 1 and the lower cavity 2 are welded by vacuum brazing .

[0038] Such as Figure 5 , 6 As shown, the upper cavity 1 and the lower cavity 2 are respectively designed with an upper waveguide cavity 103 and a lower waveguide cavity 203. After the upper and lower cavities are combined, the waveguide cavity 103 and the lower waveguide cavity 203 together form the waveguide cavity of the waveguide power divider. The waveguide cavity bifurcates in a Y shape from top to bottom, and finally forms four branch cavities. The top cavity is named a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com