A kind of ultra-low self-discharge nickel-metal hydride battery and its electrode manufacturing method

A nickel-metal hydride battery and self-discharge technology, which is applied in the manufacture of battery electrodes, nickel storage batteries, and alkaline storage batteries, etc., can solve the problems of shortening the normal service life of nickel-hydrogen batteries, loss of nickel-hydrogen battery power, and battery capacity loss, etc. Excellent recovery performance, prolonging normal service life and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

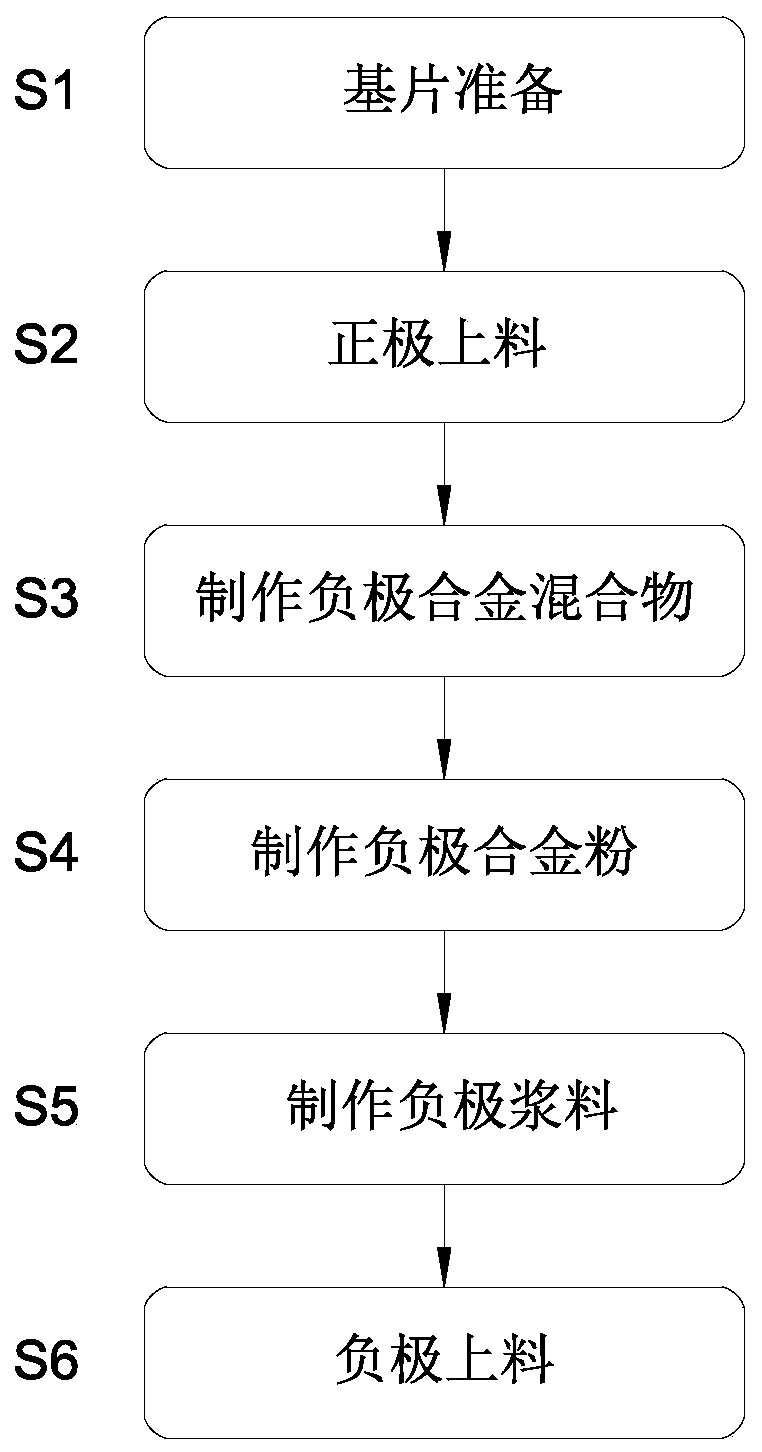

Method used

Image

Examples

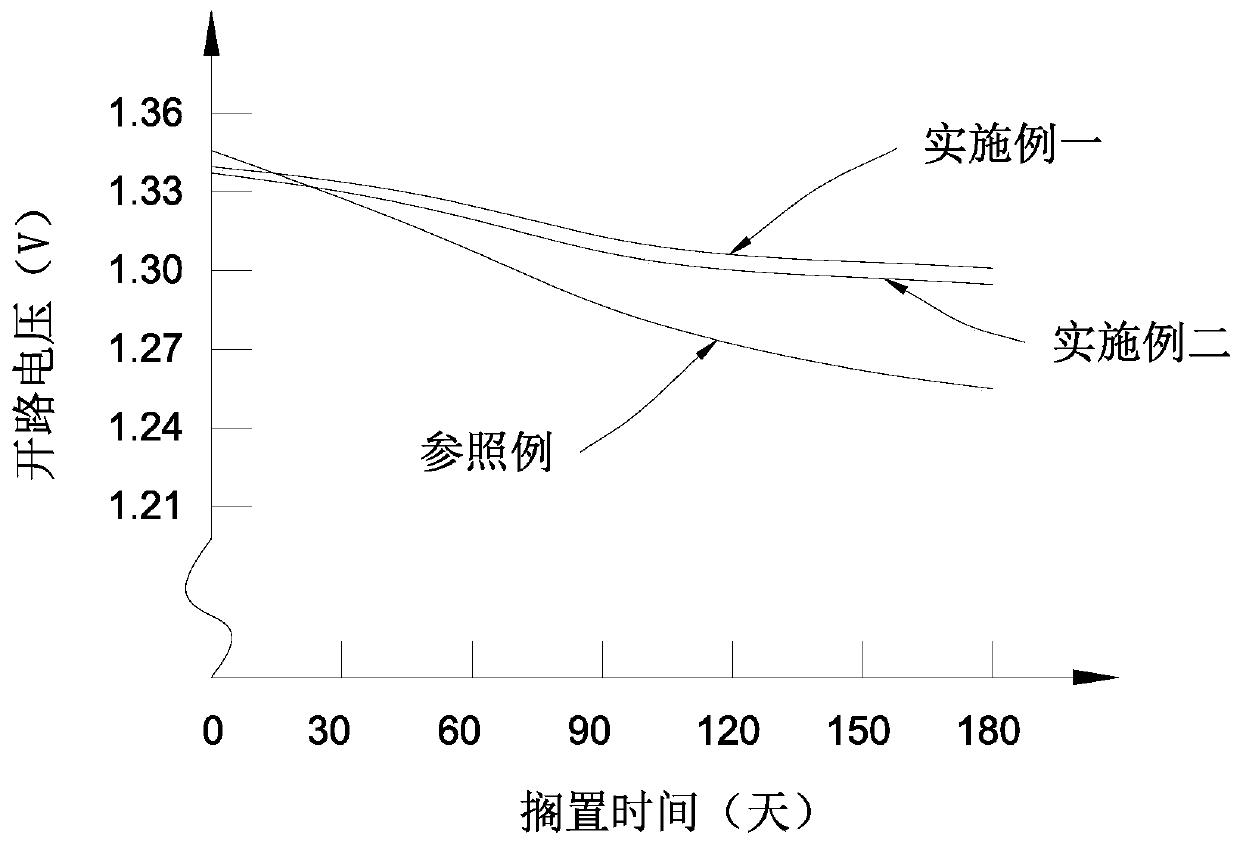

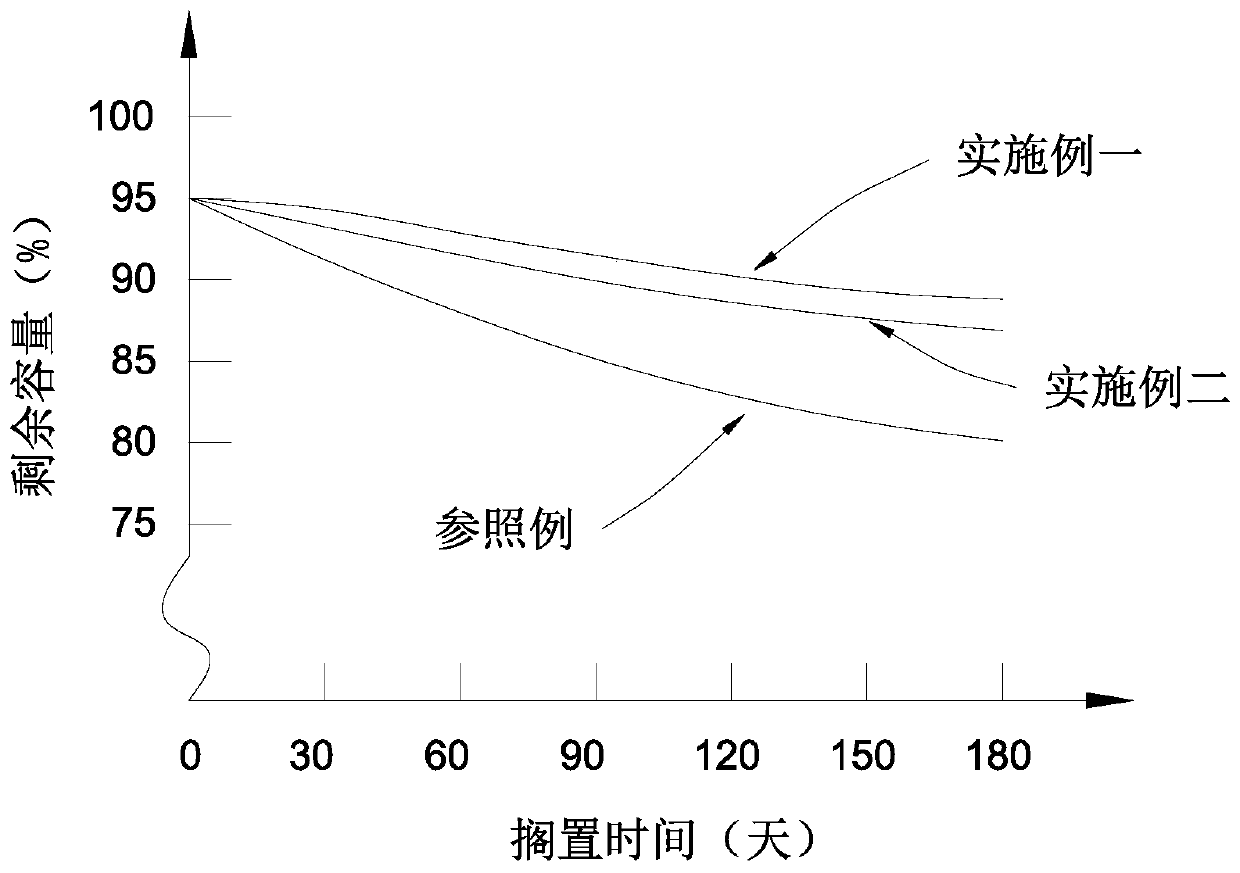

Embodiment 1

[0030] Embodiment 1, an ultra-low self-discharge nickel-metal hydride battery, including a battery case, a battery cell and an electrolyte, the battery cell includes a positive electrode sheet and a negative electrode sheet, the positive electrode sheet includes a positive electrode substrate, and each surface of the positive electrode substrate is fixed with cobalt-coated Spherical nickel layer, cobalt in cobalt-coated spherical nickel is trivalent cobalt; the negative electrode sheet includes a negative electrode substrate, each surface of the negative electrode substrate is fixed with a negative electrode coating layer, and the general formula of the alloy powder in the negative electrode coating layer is La 0.53 PR 0.87 Nd 0.99 x 0.61 Ni 8.44 A 0.56 X is Mg, Ce and Sm, and the mass percentages of each element Mg, Ce, Sm in X are 79.12%, 0.51%, 20.37% respectively; A is Al, Fe, Co and Zr, and each element Al, Fe, Co, The mass percentages of Zr in A are 94.8%, 1.46%, 0.8...

Embodiment 2

[0031] Embodiment 2, an ultra-low self-discharge nickel-metal hydride battery, including a battery case, a battery cell and an electrolyte, the battery cell includes a positive electrode sheet and a negative electrode sheet, the positive electrode sheet includes a positive electrode substrate, and each surface of the positive electrode substrate is fixed with cobalt-coated Spherical nickel layer, cobalt in cobalt-coated spherical nickel is trivalent cobalt; the negative electrode sheet includes a negative electrode substrate, each surface of the negative electrode substrate is fixed with a negative electrode coating layer, and the general formula of the alloy powder in the negative electrode coating layer is La 0.57 PR 0.83 Nd 0.92 x 0.68 Ni 8.12 A 0.88 X is Mg, Ce and Sm, and the mass percentages of each element Mg, Ce, Sm in X are 76.52%, 0.78%, 22.7% respectively; A is Al, Fe, Co and Zr, and each element Al, Fe, Co, The mass percentages of Zr in A are 93.71%, 2.1%, 0.59...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com