Method for decreasing MOD type silver ink film defects by adjusting ink droplet spacing

A thin film defect and spacing technology, applied to the conductive layer, electrical components, circuits, etc. on the insulating carrier, can solve the problems of complex theory and principle, increase the time and cost required for the process, and cumbersome implementation process, and achieve a uniform and flat surface , the effect of reducing time and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

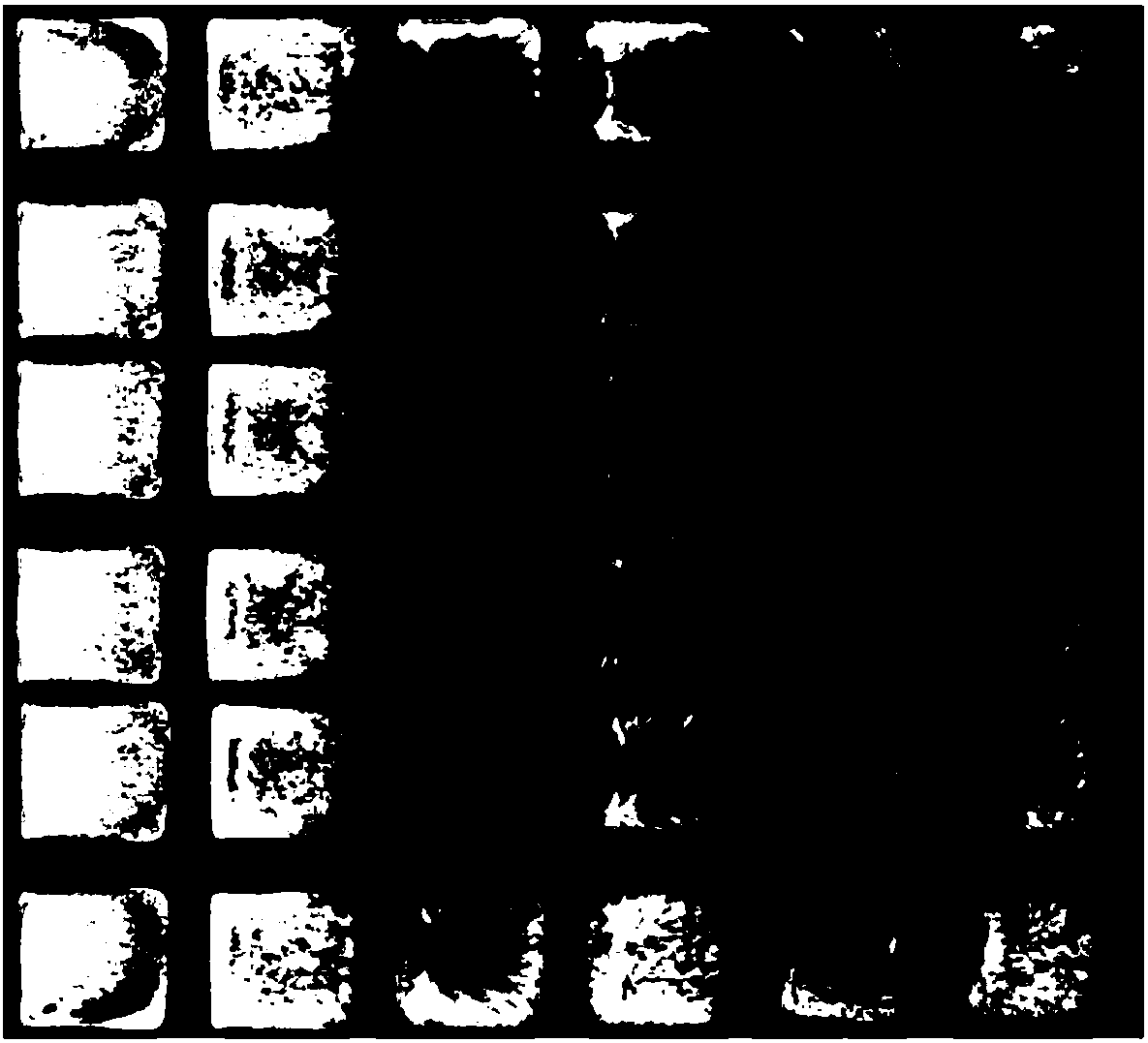

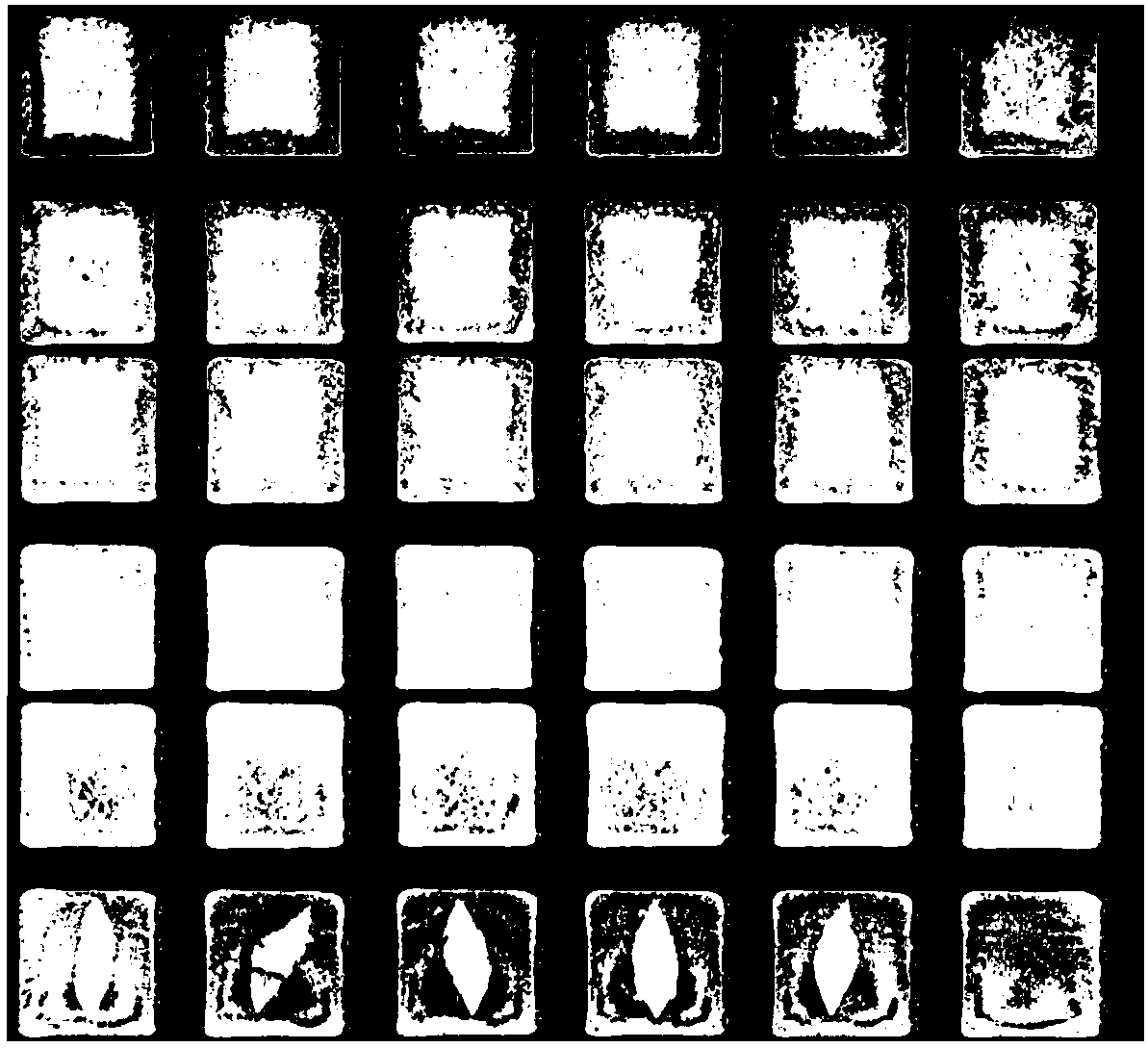

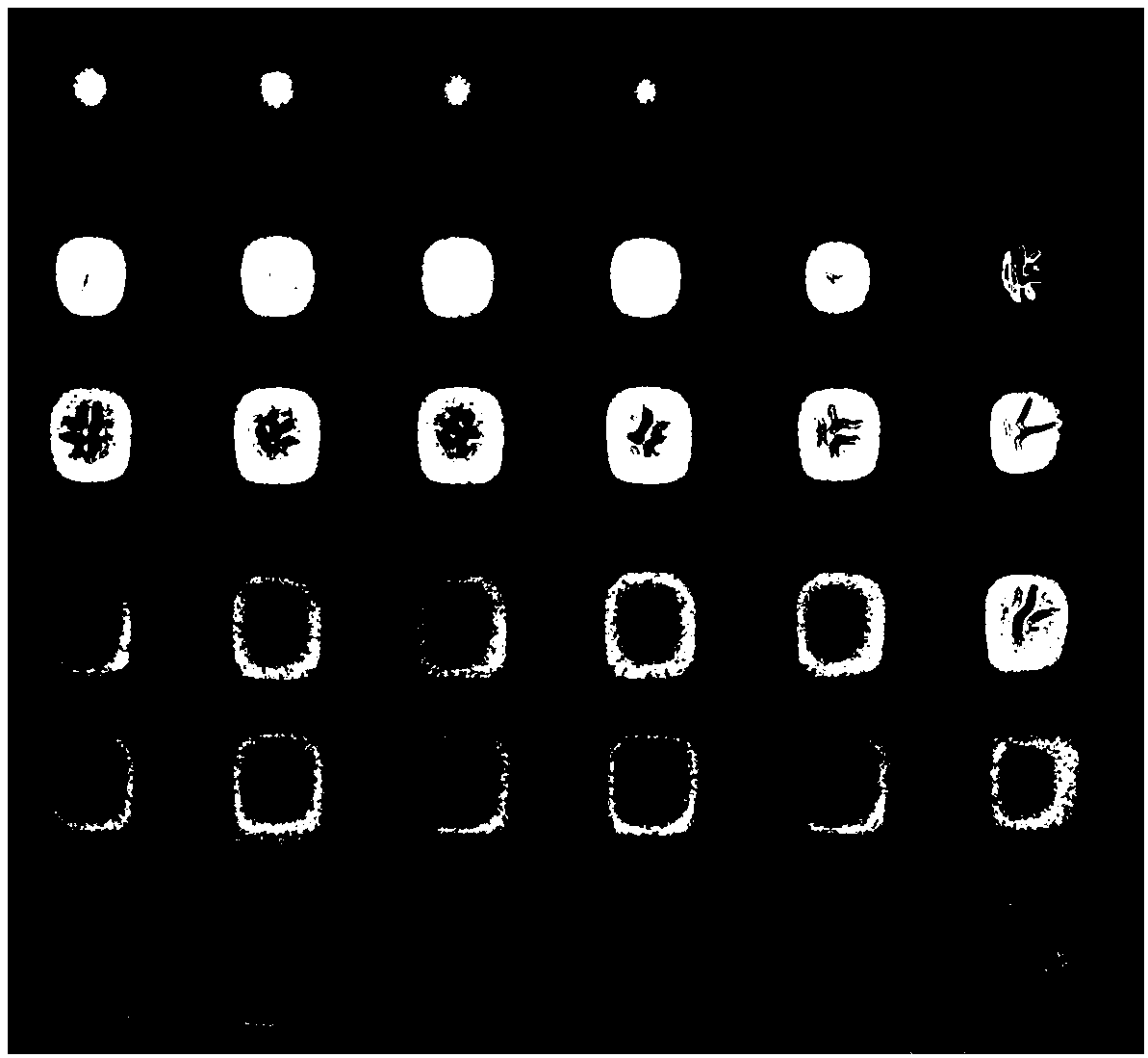

Image

Examples

Embodiment 1

[0032] (1) Wash the substrate of a glass sheet with a length and width of 1cm×1cm and a thickness of about 0.7mm with isopropanol, tetrahydrofuran, alkaline cleaning solution, deionized water for the first time, deionized water for the second time, and isopropanol. Vibrate each step with an ultrasonic cleaner for 5-10 minutes. Then put the cleaned substrate into an oven and dry it at 80-85°C.

[0033] (2) adopt TEC-IJ-010MOD solution type silver ink with printer (Dimatix DMP-2800 printer) (purchase from Korea InkTec company; Solid content is 15%, and viscosity is 9~15cps, and surface tension is 30~32dynes / cm, The solvent used is ethanol, the recommended sintering temperature is 130°C-150°C, and the reference resistivity is 4.2μΩ·cm), and the preset graphics are printed on the substrate after cleaning and drying in step (1), where the printing parameters are set as follows: The distance between the nozzle and the substrate is 1000 μm, the distance between ink droplets is 15 μm...

Embodiment 2

[0037] (1) Wash the substrate of a glass sheet with a length and width of 1cm×1cm and a thickness of about 0.7mm with isopropanol, tetrahydrofuran, alkaline cleaning solution, deionized water for the first time, deionized water for the second time, and isopropanol. Vibrate each step with an ultrasonic cleaner for 5-10 minutes. Then put the cleaned substrate into an oven and dry it at 80-85°C.

[0038] (2) adopt TEC-IJ-010MOD solution type silver ink with printer (Dimatix DMP-2800 printer) (purchase from Korea InkTec company; Solid content is 15%, and viscosity is 9~15cps, and surface tension is 30~32dynes / cm, The solvent used is ethanol, the recommended sintering temperature is 130°C-150°C, and the reference resistivity is 4.2μΩ·cm), and the preset graphics are printed on the substrate after cleaning and drying in step (1), where the printing parameters are set as follows: The distance between the nozzle and the substrate is 1000 μm, the distance between ink droplets is 20 μm...

Embodiment 3

[0042] (1) Wash the substrate of a glass sheet with a length and width of 1cm×1cm and a thickness of about 0.7mm with isopropanol, tetrahydrofuran, alkaline cleaning solution, deionized water for the first time, deionized water for the second time, and isopropanol. Vibrate each step with an ultrasonic cleaner for 5-10 minutes. Then put the cleaned substrate into an oven and dry it at 80-85°C.

[0043] (2) adopt TEC-IJ-010MOD solution type silver ink with printer (Dimatix DMP-2800 printer) (purchase from Korea InkTec company; Solid content is 15%, and viscosity is 9~15cps, and surface tension is 30~32dynes / cm, The solvent used is ethanol, the recommended sintering temperature is 130°C-150°C, and the reference resistivity is 4.2μΩ·cm), and the preset graphics are printed on the substrate after cleaning and drying in step (1), where the printing parameters are set as follows: The distance between the nozzle and the substrate is 1000 μm, the distance between ink droplets is 25 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com