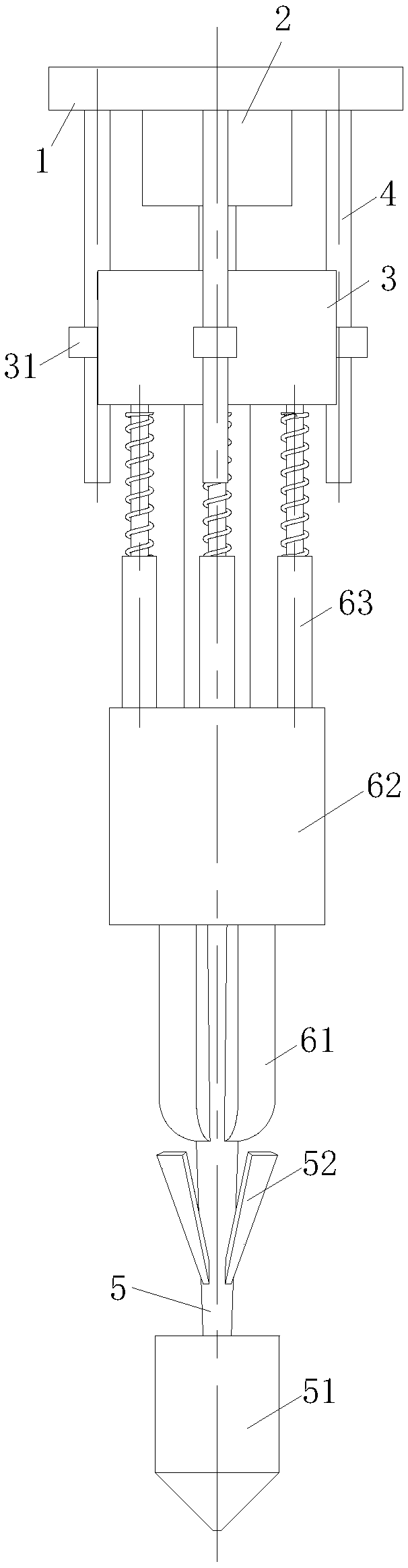

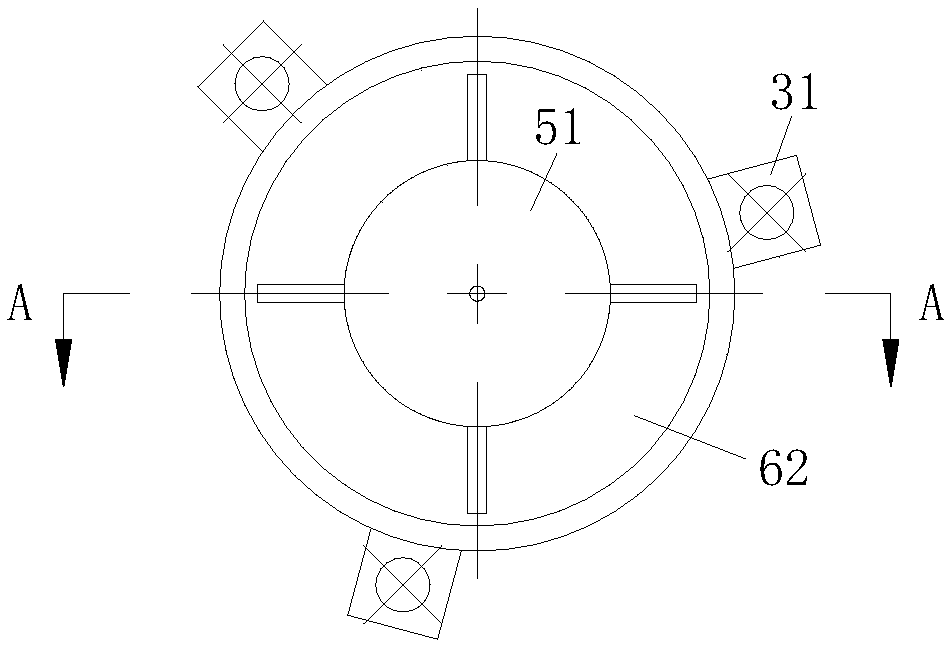

Rock drilling and braking integrated machine

An all-in-one machine and rock drill technology, which is used in earth-moving drilling, slitting machinery, and open-pit mining, etc., can solve the problems of many connection points, large positioning errors, large tolerances, etc. The effect of positioning and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

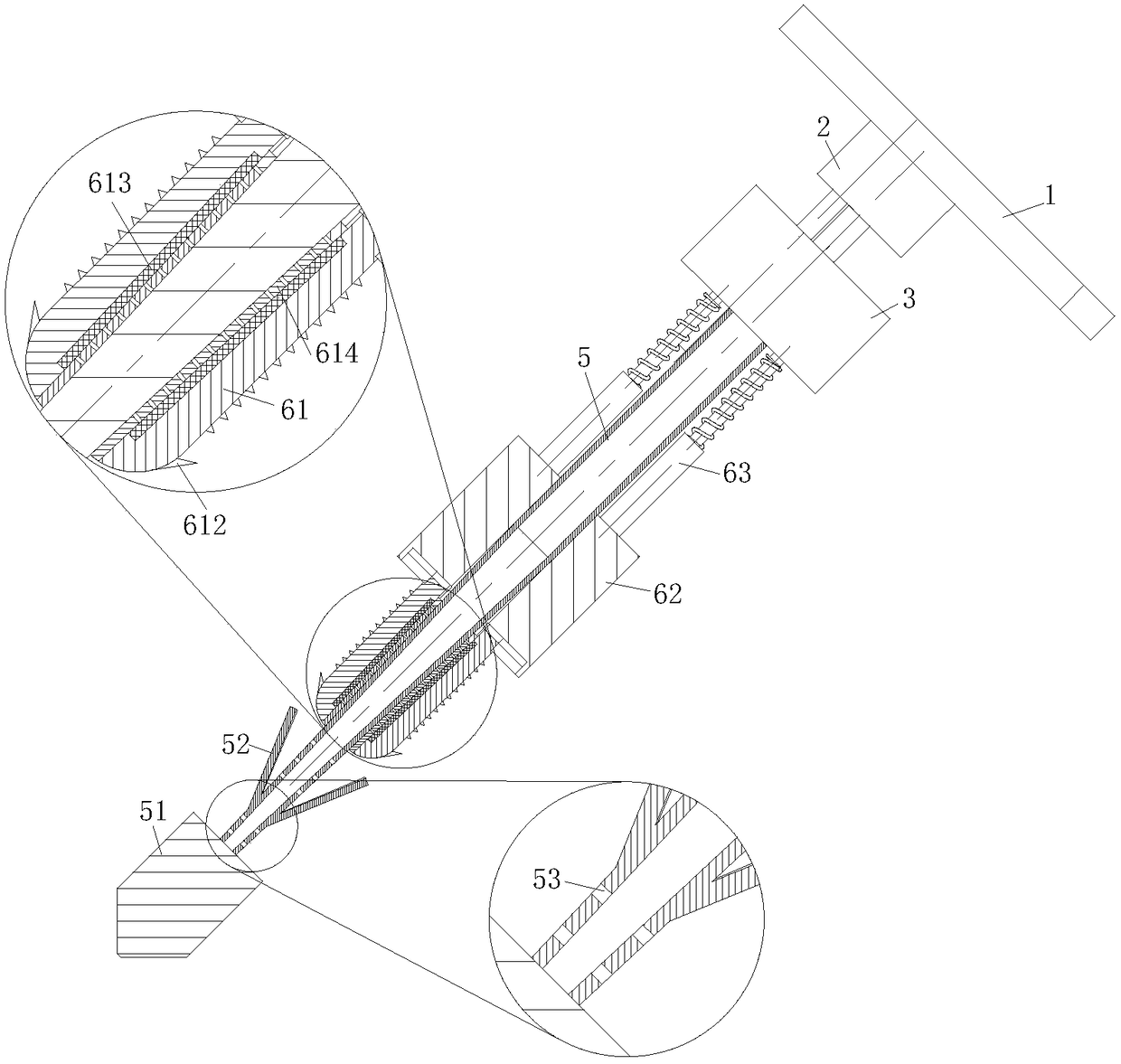

[0029] As an embodiment of the present invention, the lower end of the wedge 61 is provided with a barb 612, and the barb 612 is used to turn up the broken stone. The rock blocks are lifted to loosen them.

[0030] As an embodiment of the present invention, the outer surface of the wedge 61 is provided with a sharp cone, which prevents the wedge 61 from protruding from the hole when it is pressed against the rock wall on the one hand, and on the other hand, because the contact surface is small and the pressure at the tip is strong, In the early stage of extrusion, micro cracks are formed in the rock, which improves the crushing capacity of the wedge 61 .

[0031]As an embodiment of the present invention, the inside of the wedge 61 is provided with a cavity, the cavity is provided with a sponge 613, the inner surface of the wedge 61 is provided with an elastic steel plate 614, and the elastic steel plate 614 is provided with a There is a group of micro-perforations, and the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com