Cotton straw supporting structure for cemented soil mixing pile

A technology for cement-soil mixing piles and cotton straws, which is applied to foundation structure engineering, sheet pile walls, excavation, etc., can solve the problems of ground disturbance, limited length of bamboo reinforcement, and high use cost, and achieves enhanced support capacity and enhanced reinforcement. Effective, highly economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

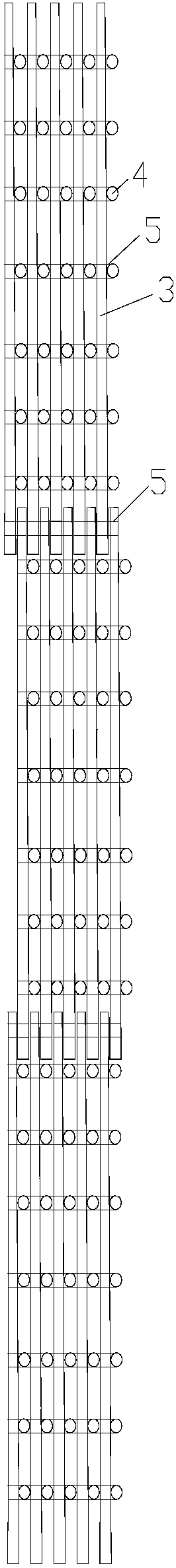

[0027] The cotton stalk support structure used for the cement-soil mixing pile of this embodiment, such as Figure 1-Figure 4 As shown, it is composed of a plurality of cotton stalk grids that are overlapped together. The cotton stalk grid includes multiple layers of cotton stalk meshes that are stacked together. The cotton stalk meshes are vertically arranged. It is made by binding a plurality of cotton stalks along the vertical and horizontal directions respectively, that is, the longitudinal cotton stalks 3 and the horizontal cotton stalks 4 are bound by binding iron wires 5 .

[0028]In this embodiment, the cotton stalk grid is formed by superimposing and binding the cotton stalk mesh, which can be made into a prefabricated part. Among them, the single-layer cotton stalk mesh is formed by binding a single cotton stalk orthogonally in the vertical and horizontal directions. During the binding process, it is necessary to pay attention to the bifurcation direction of the natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com