Washing machine detergent box and washing machine

A technology for a detergent box and a washing machine, applied in the field of washing machines, can solve the problems of inability to strengthen its own strength, bad touch, breakage, etc., and achieve the effects of good hand feeling, prolonging service life and avoiding breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

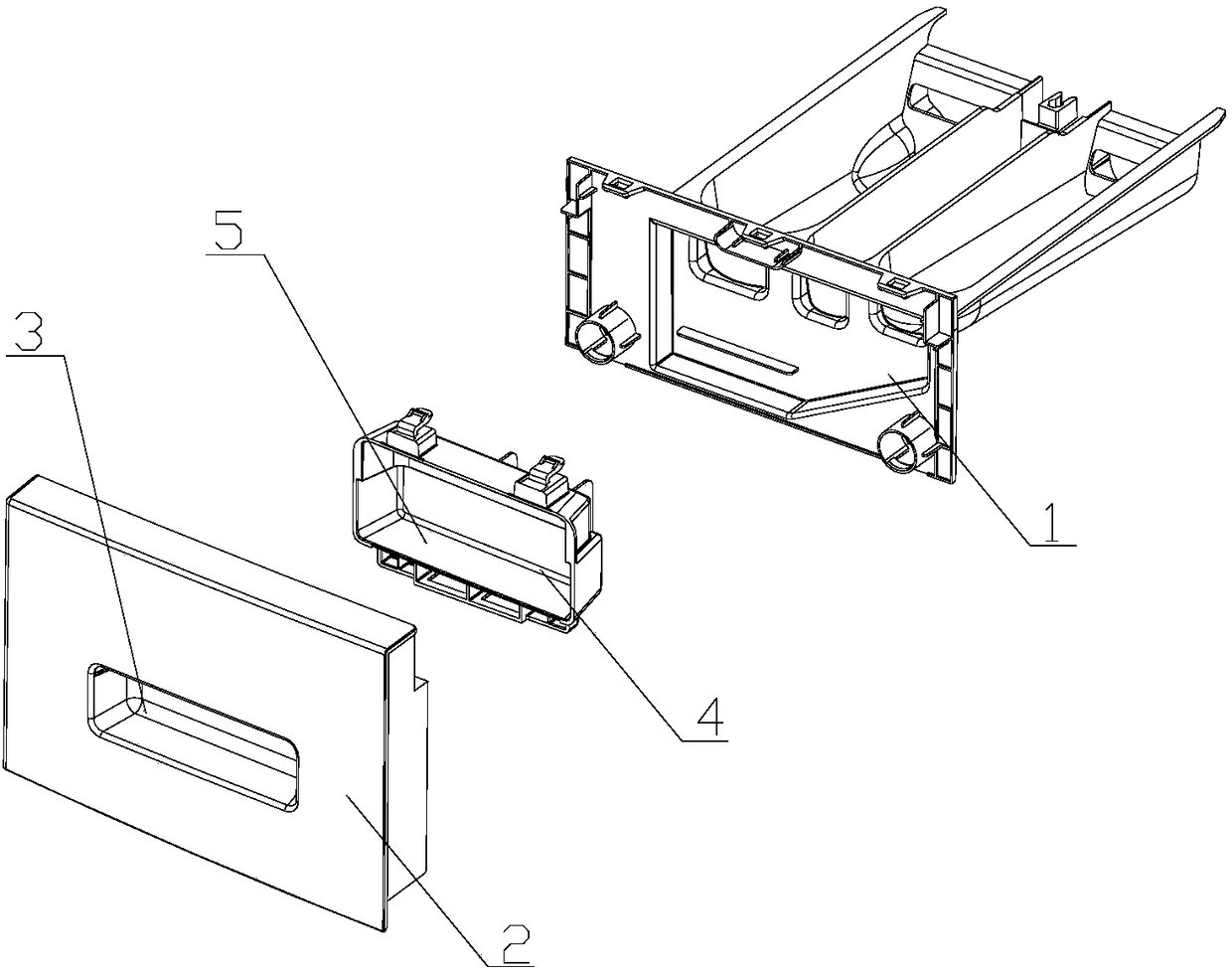

[0054] Such as figure 1 As shown, the isolation mechanism 4 of this embodiment is assembled on the front panel 2 and / or the detergent box body 1 , and the opening of the accommodating chamber 5 is opposite to the opening 3 on the front panel 2 .

[0055] The isolating mechanism can be connected with the front panel at the front end, or with the detergent box body at the rear end, or both at the same time. The connection can be a fixed connection, a detachable connection, or integral molding. Regardless of the connection method, as long as the isolation mechanism can be fixed between the front panel and the detergent box body.

[0056] Regardless of the connection mode, the opening of the accommodating chamber of the isolating mechanism must be arranged opposite to the opening on the front panel, so that the opening of the front panel communicates with the accommodating chamber of the isolating mechanism. After the isolation mechanism is connected to the front panel and / or the...

Embodiment 2

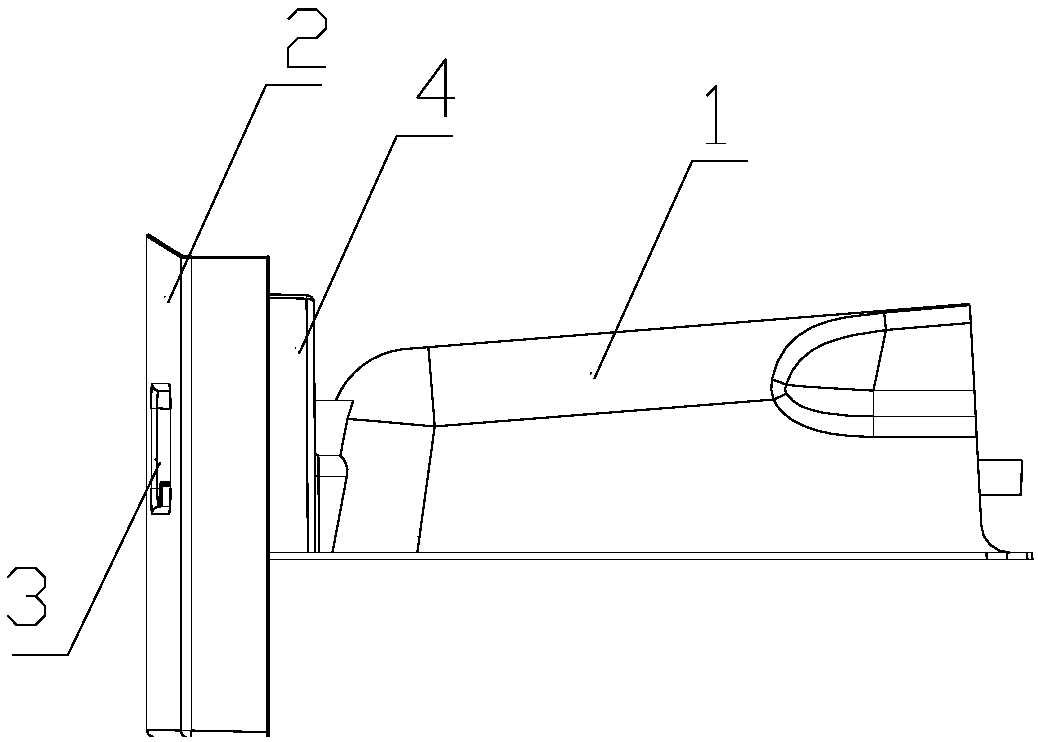

[0078] Such as Figure 2-Figure 7 As shown, this embodiment is a further limitation of Embodiment 1. The isolation mechanism 4 of this embodiment is connected to the front panel 2. After the connection, the opening of the accommodation chamber 5 of the isolation mechanism 4 is located at the outer edge of the opening 3 of the front panel. , the bottom wall of the accommodating chamber 5 faces the detergent box body 1 and abuts against the detergent box body 1 .

[0079] The isolating mechanism is connected with the front panel at the front end, and leans against the detergent box body at the rear end, so that there is support between the front panel and the detergent box body. During transportation, when the front panel is subjected to a large impact force, due to the existence of the isolation mechanism, the self-strength and impact resistance of the front panel and the opening of the front panel can be greatly enhanced to avoid breakage during transportation, and it can also...

Embodiment 3

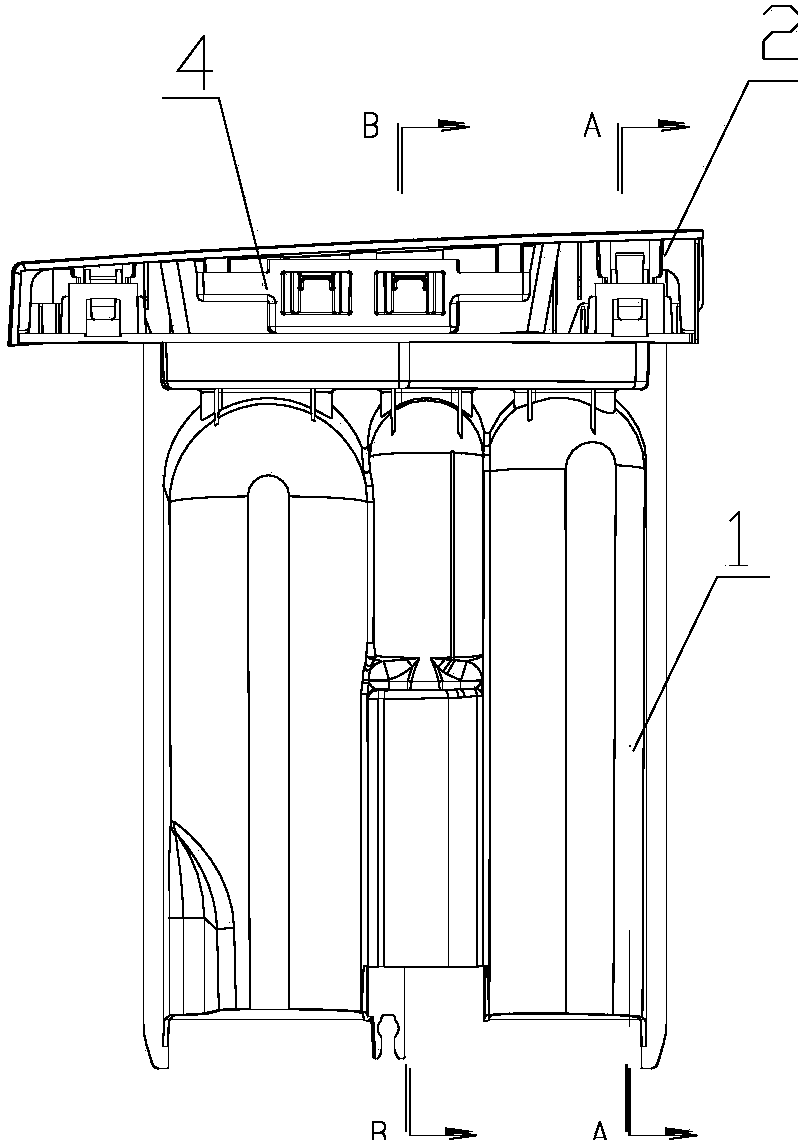

[0081] Such as Figure 11-Figure 15 As shown, this embodiment is a further limitation of Embodiment 1 or Embodiment 2. The inner surface of the accommodating chamber 5 of this embodiment is made of flexible materials, and the bottom surface of the accommodating chamber 5 facing the detergent box body 1 is provided with The reinforcing ribs 16, preferably, the reinforcing ribs 16 include transverse reinforcing ribs and vertical reinforcing ribs arranged crosswise.

[0082] The reinforcing ribs provided on the bottom surface of the accommodating chamber facing the detergent box body can strengthen the strength of the isolation mechanism itself, and can further increase the impact resistance of the front panel and the opening of the front panel, avoiding breakage during transportation, avoiding loss, and reducing costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com