High-performance steel-based copper alloy graphite composite material

A composite material, copper alloy technology, applied in the direction of analyzing materials, testing material hardness, testing wear resistance, etc. It does not have the problems of corrosion resistance, wear resistance and seizure resistance, and achieves the effect of excellent interface, high strength and reduced porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

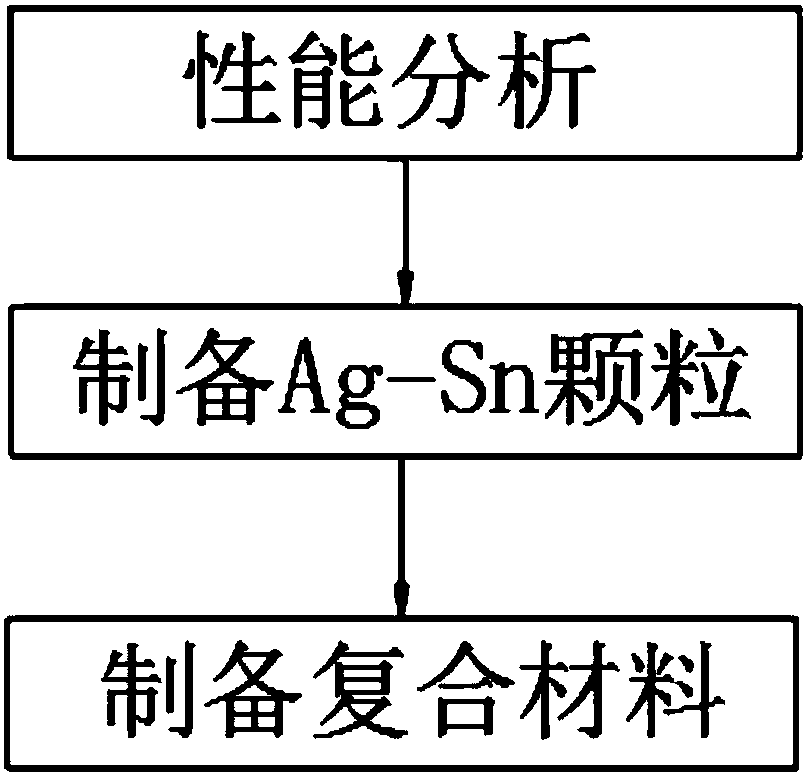

[0019] Embodiment 1: as figure 1 Shown, the present invention provides a kind of high performance steel base copper alloy graphite composite material, the preparation raw material of the material in the described steel base copper alloy graphite self-lubricating composite material comprises: Sn, graphite, Ni, Cu, boron and Fe, wherein The mass percentages of the raw materials for the preparation of the steel-based copper alloy graphite self-lubricating composite material are: Sn: 6%, graphite: 9%, Ni: 11%, Cu: 34%, boron: 0.005% and Fe: 48%.

[0020] According to the above technical scheme, the preparation method of the high-performance steel-based copper alloy graphite composite material comprises the following steps:

[0021] 1) Performance analysis: SEM, EDS, XRD, HRTEM and other analytical methods are used to analyze the phase composition of graphite, nickel, and boron, and electronic universal testing machines, hardness testers, density meters, and friction and wear testi...

Embodiment 2

[0029] Embodiment 2: as figure 1 Shown, the present invention provides a kind of high performance steel base copper alloy graphite composite material, the preparation raw material of the material in the described steel base copper alloy graphite self-lubricating composite material comprises: Sn, graphite, Ni, Cu, boron and Fe, wherein The mass percentages of raw materials for the preparation of the steel-based copper alloy graphite self-lubricating composite material are: Sn: 4%, graphite: 7%, Ni: 9%, Cu: 34%, boron: 0.05%wt and Fe: 48%.

[0030] According to the above technical scheme, the preparation method of the high-performance steel-based copper alloy graphite composite material comprises the following steps:

[0031] 1) Performance analysis: SEM, EDS, XRD, HRTEM and other analytical methods are used to analyze the phase composition of graphite, nickel, and boron, and electronic universal testing machines, hardness testers, density meters, and friction and wear testing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com