A beneficiation process for recovering fine-grained and fine-grained cassiterite from tailings

A technology of fine particles and tailings, which is applied in the direction of mechanical material recovery, recycling technology, solid separation, etc. Improve desliming effect, eliminate adverse effects, reduce gangue content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

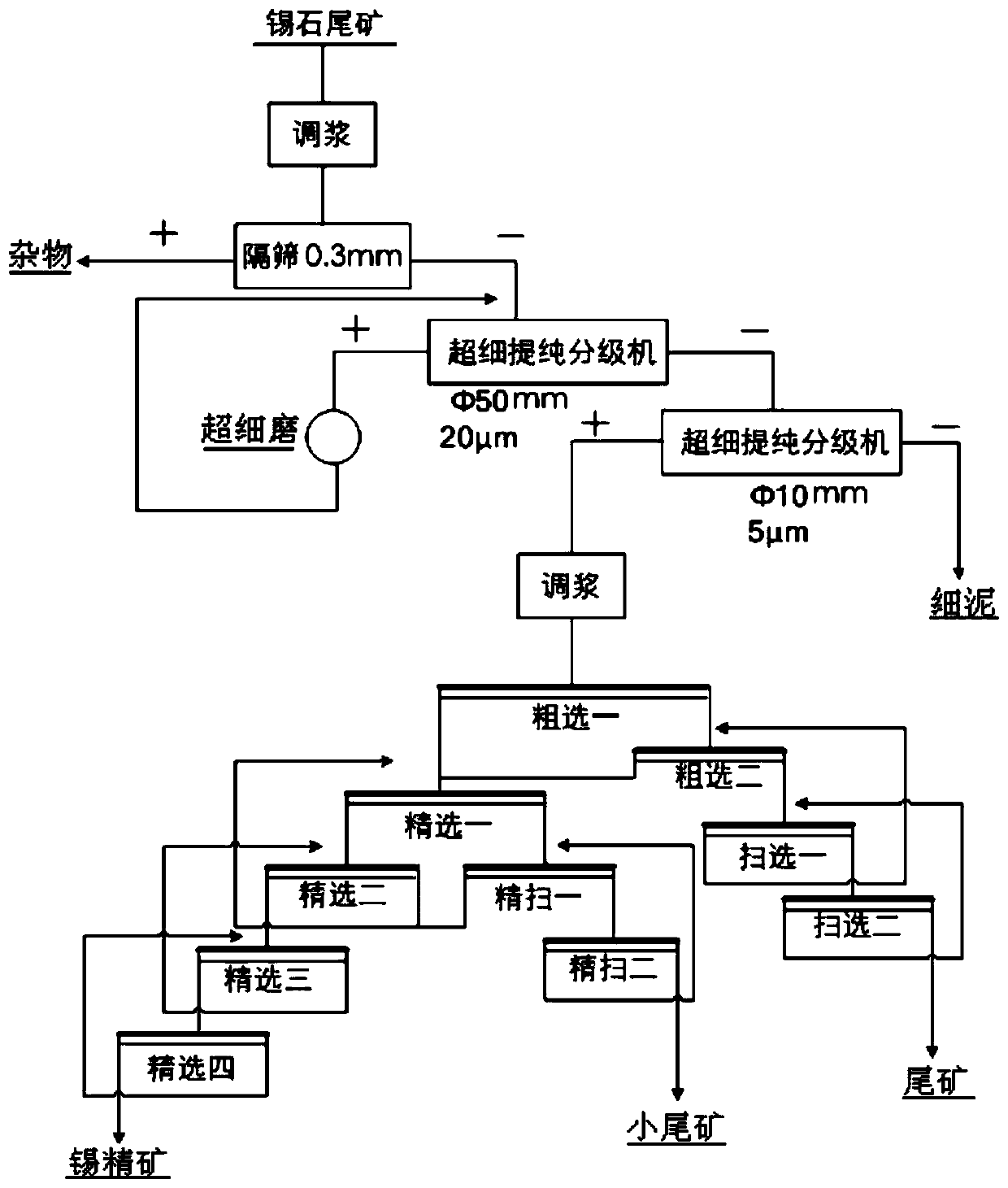

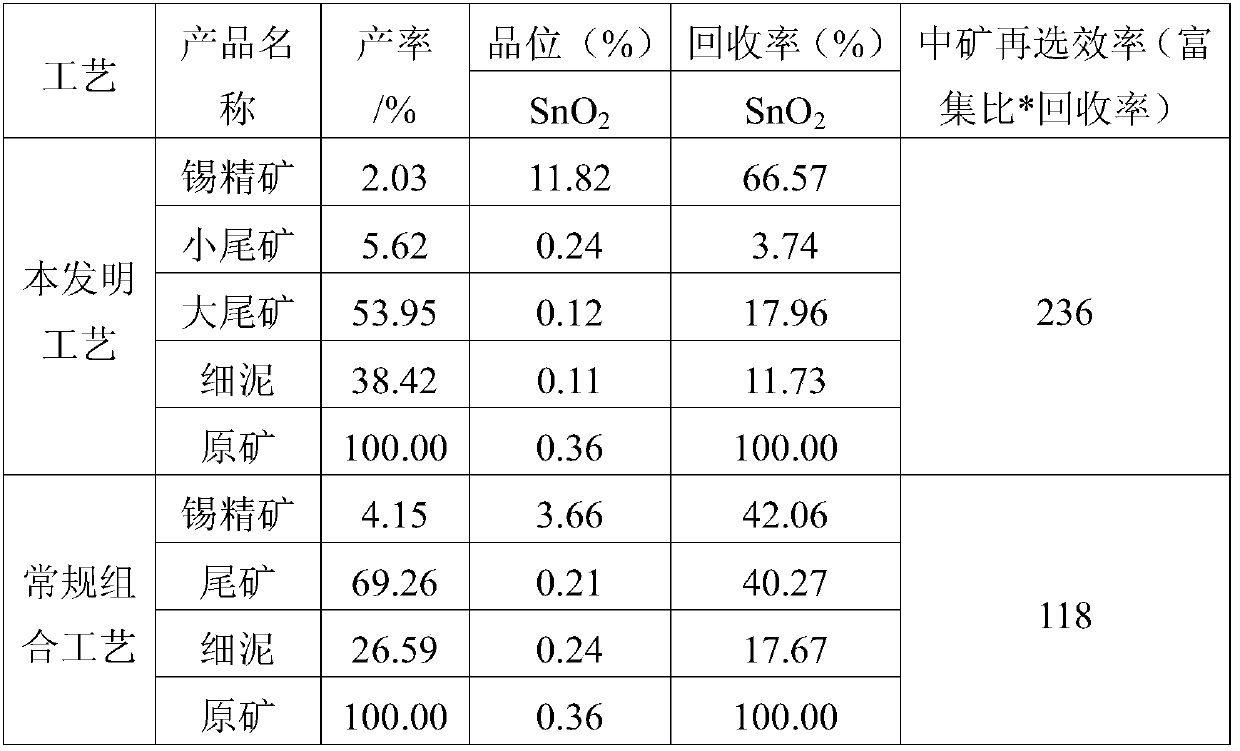

[0036] In a gravity-selected tin-bearing tailings in Yunnan, the tin-containing minerals in the ore are mainly cassiterite, and the loss form of cassiterite mainly exists in the form of tin inclusions, with an average particle size of 15 μm and a monomer dissociation degree of 32.05%. Stone minerals are mainly mica, quartz and feldspar. The tailings contain 0.36% tin.

[0037] Utilize the method of the present invention, after this tailings slurry is passed through the screen, enter the superfine purification classifier of φ50mm, the concentration is 8% (weight ratio), and the slurry feeding pressure is 0.50MPa; The flow enters the φ10mm ultra-fine purification classifier, the slurry inlet pressure is 0.85MPa, the φ50mm ultra-fine purification classifier is sanded (+20μm) and then ultra-finely ground after concentration. The grinding fineness is -0.010mm 80%. The finished pulp is then returned to the φ50mm ultra-fine purification classifier to form a closed loop. The overflo...

Embodiment 2

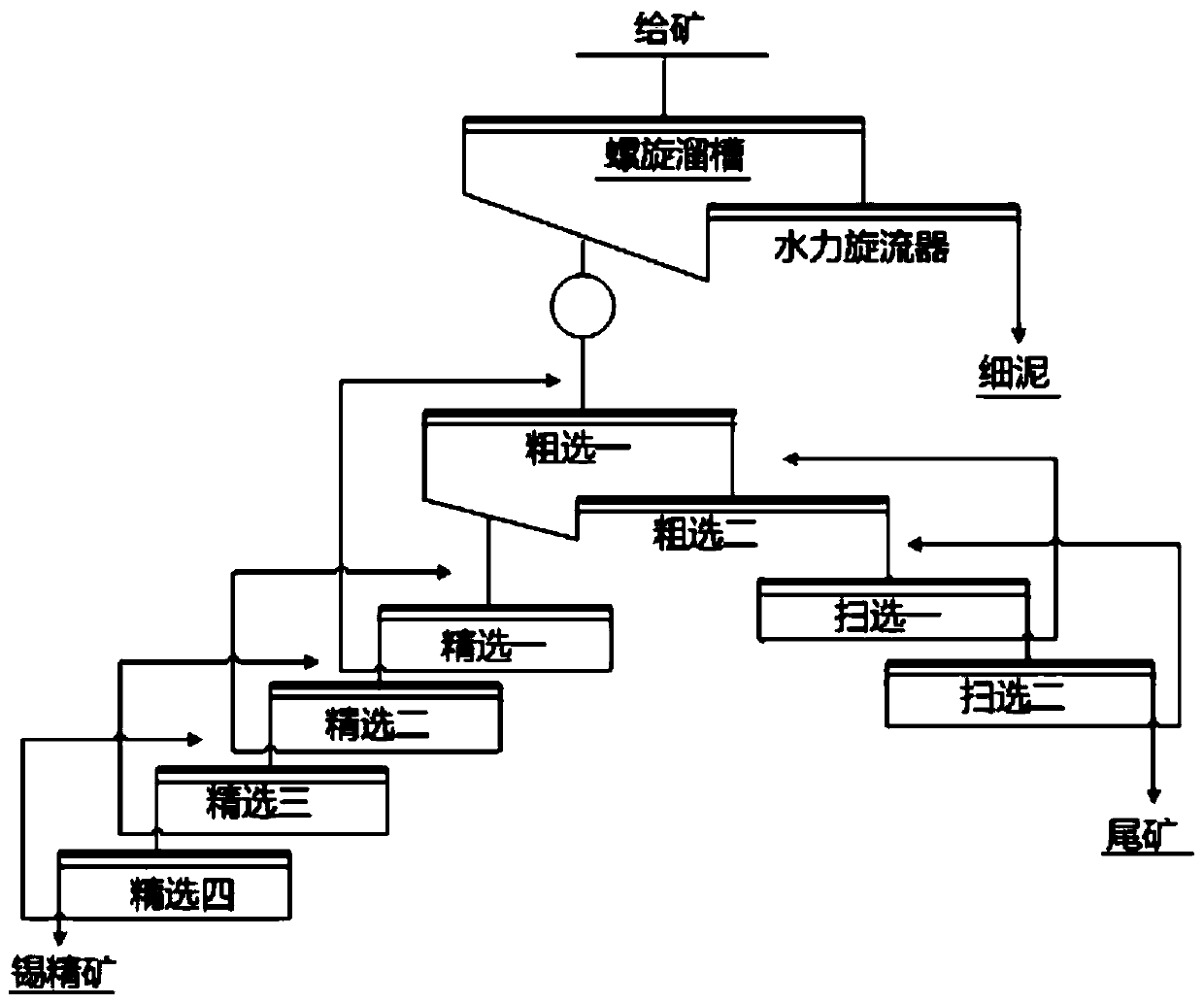

[0042]In an old tin-bearing mine tailings in Guangxi, the tin-containing minerals in the ore are mainly cassiterite, and the loss form of cassiterite in the tailings is finely embedded inclusions, with an average embedded particle size of 18 μm. Gangue minerals are mainly sericite, quartz and kaolinite. The tailings contain 0.41% tin.

[0043] Utilize the method of the present invention, after this tailings slurry is passed through the screen, enter the ultrafine purification classifier of φ50mm, the concentration is 10% (weight ratio), and the slurry feeding pressure is 0.46MPa; The overflow of the ultrafine purification classifier of φ50mm The flow enters the φ10mm ultra-fine purification classifier, the slurry inlet pressure is 0.94MPa, and the φ50mm ultra-fine purification classifier is sanded (+20μm) and then ultra-finely ground after concentration. The grinding fineness is -0.010mm 86%. The finished pulp is then returned to the φ50mm ultra-fine purification classifier t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com