Measuring arm with self-balance shaft

A measuring arm and self-balancing technology, which is applied in the direction of measuring devices and instruments, can solve the problems of increasing the overall volume and weight of the balance shaft, the large horizontal length of the balance shaft of the measuring arm, large labor and time costs, etc., to reduce the volume and weight, ensure the consistency of accuracy, and reduce the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

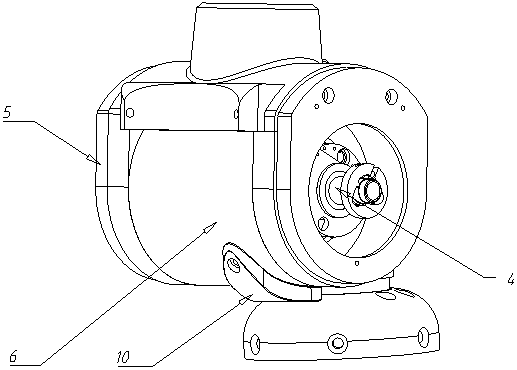

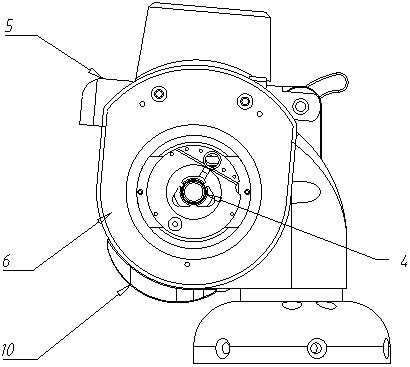

[0031] Such as Figure 1-5 The shown measuring arm with a self-balancing shaft includes: a fixed shaft 6, the fixed shaft 6 is a hollow structure, and the rear end surface of the fixed shaft 6 is provided with an axial fixed shaft annular groove 61;

[0032] The rotating sleeve 5, the rotating sleeve 5 includes a rotating side cover 51 corresponding to the rear end surface of the fixed shaft 6 and an upper cover arc plate 52 axially parallel to the fixed shaft 6; the inner surface of the rotating side cover 51 is provided There is a groove 53 in the rotating sleeve, and the groove 53 in the rotating sleeve corresponds to the annular groove 61 of the fixed shaft;

[0033] A connecting shaft 4, the connecting shaft 4 is rotationally connected with the fixed shaft 6 through the bearing mechanism 2, and one end of the connecting shaft 4 is connected with the rotating side cover 51;

[0034] A balance torsion spring 8, the balance torsion spring 8 is arranged in the annular groove...

Embodiment 2

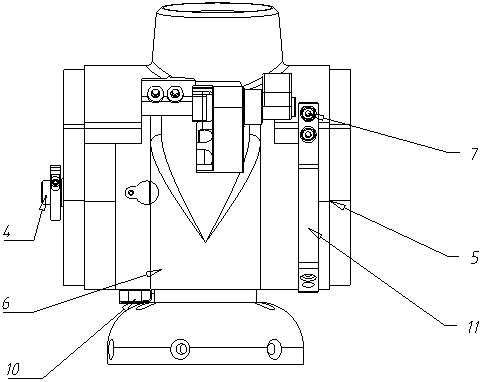

[0038] Such as Figure 1-9 The shown measuring arm with a self-balancing shaft includes: a fixed shaft 6, the fixed shaft 6 is a hollow structure, and the rear end surface of the fixed shaft 6 is provided with an axial fixed shaft annular groove 61;

[0039] The rotating sleeve 5, the rotating sleeve 5 includes a rotating side cover 51 corresponding to the rear end surface of the fixed shaft 6 and an upper cover arc plate 52 axially parallel to the fixed shaft 6; the inner surface of the rotating side cover 51 is provided There is a groove 53 in the rotating sleeve, and the groove 53 in the rotating sleeve corresponds to the annular groove 61 of the fixed shaft;

[0040] A connecting shaft 4, the connecting shaft 4 is rotationally connected with the fixed shaft 6 through the bearing mechanism 2, and one end of the connecting shaft 4 is connected with the rotating side cover 51;

[0041] A balance torsion spring 8, the balance torsion spring 8 is arranged in the annular groove 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com