Anti-corrosion APU cabin partition sealing strip

A technology for sealing strips and cabin partitions, which is applied to the sealing of engines, engine components, mechanical equipment, etc., can solve the problems of shortening the service life of the sealing strips, deformation of the sealing strips, poor rebound effect, etc. The effect of rebound and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

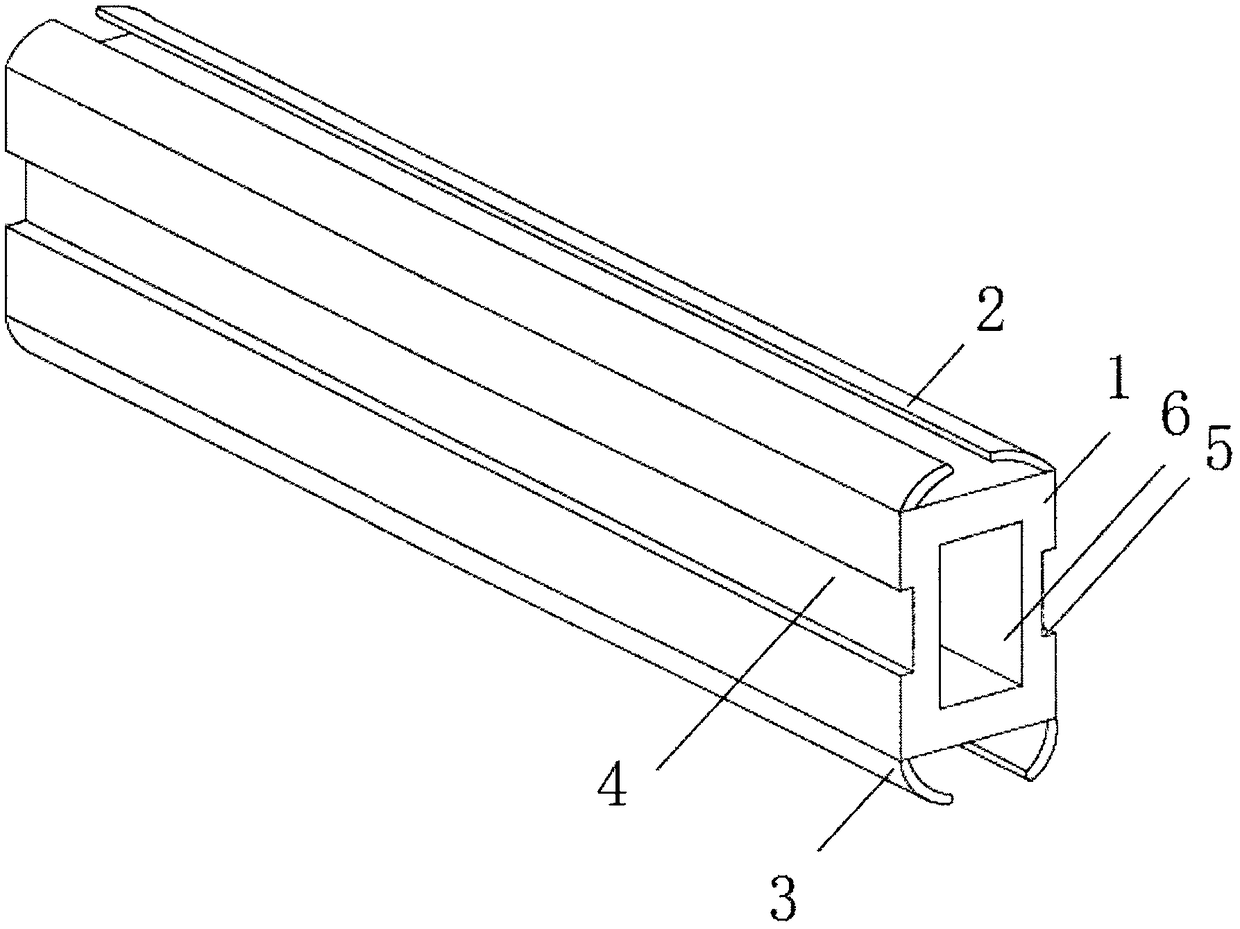

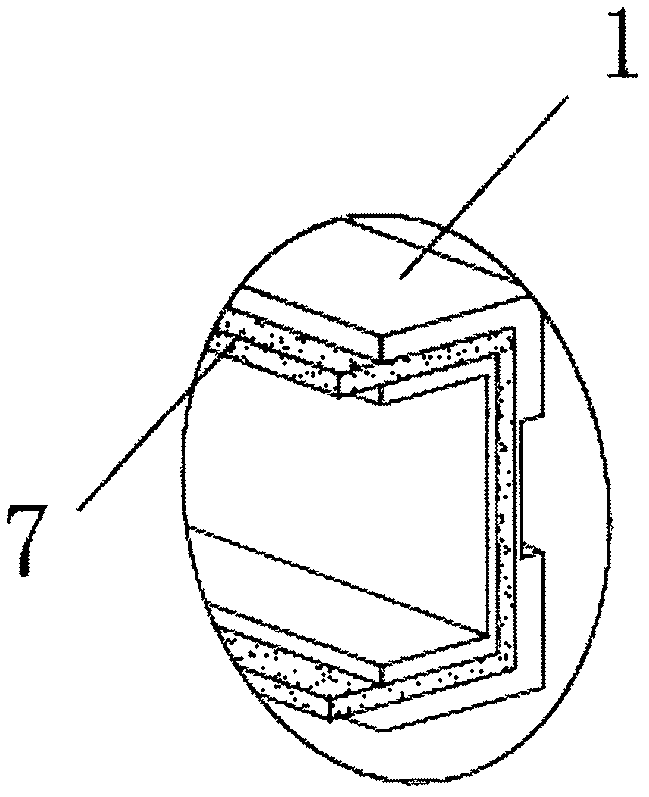

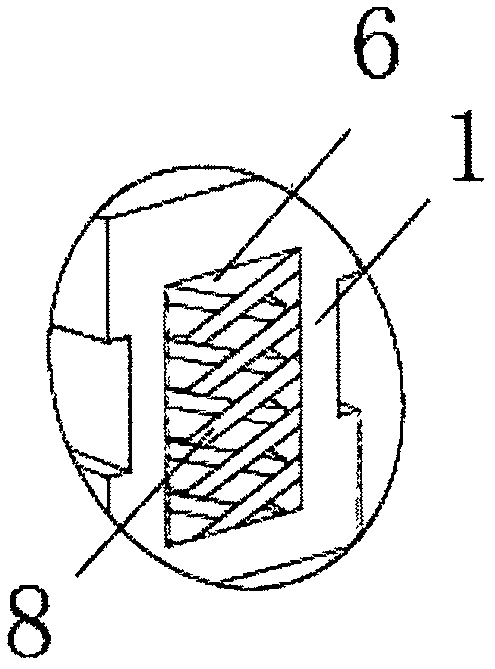

[0020] Such as Figure 1-4 As shown, a kind of anti-corrosion type APU compartment partition sealing strip includes a sealing strip main body 1, the outer surface of the upper end of the sealing strip main body 1 is fixedly installed with a No. No. 1 fitting blade 3, one side of the outer surface of the sealing strip main body 1 is fixedly installed with the No. 1 sliding card slot 4, and the other side of the outer surface of the sealing strip main body 1 is fixedly installed with the No. The inner surface is fixedly equipped with a notch 6, and the inside of the sealing strip main body 1 is fixedly installed with an insulating plate 7, and both sides of the inner wall of the notch 6 are fixedly installed with fiber strips 8, and the outer surface of the sealing strip main body 1 is fixedly installed with PVC soft plate 9.

[0021] The number of No. 1 fitting blade 2 and No. 2 fitting blade 3 are two groups, and the outer surfaces of No. 1 fitting blade 2 and No. 2 fitting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com