On-line activation structure and on-line activation method of adsorption part of superconducting cable heat insulation tube

A technology of superconducting cables and adsorbents, which is applied in the direction of protecting pipelines, pipes/pipe joints/fittings, and pipelines through heat insulation, and can solve the problems of reduced adsorption capacity, failure, and short vacuum life of conductive cable insulation tubes, etc. Achieve the effect of simplifying the maintenance process and improving the vacuum life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

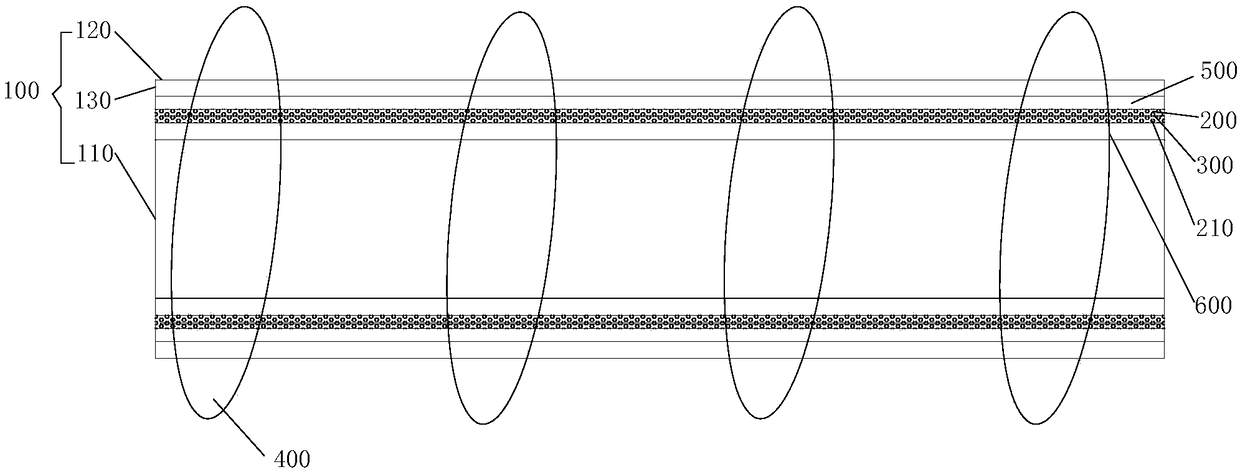

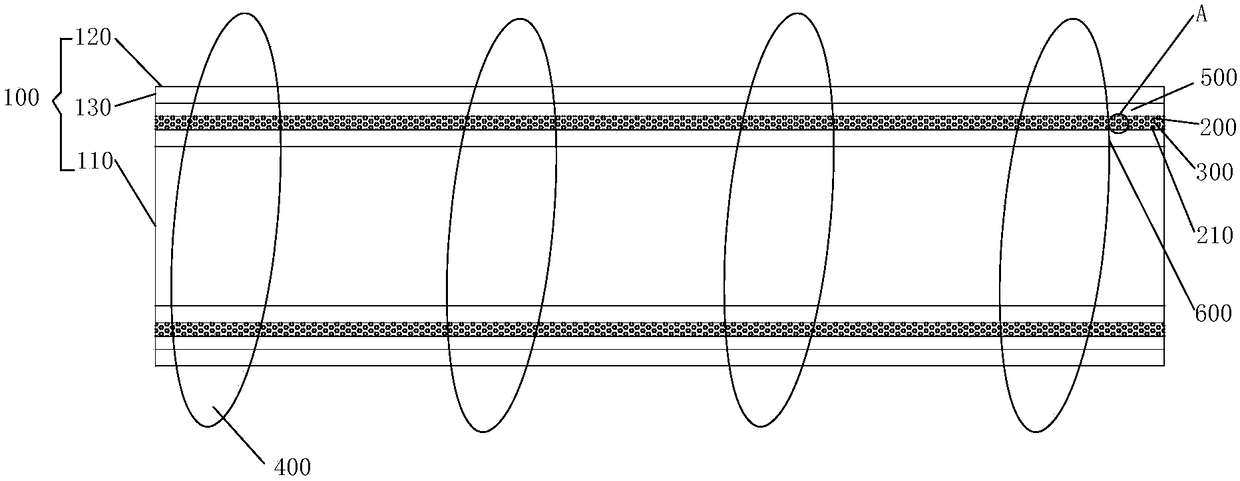

[0033] Such as figure 1 As shown, the online activation structure and online activation method of the adsorption member 210 of the superconducting cable heat insulating tube in this embodiment, the superconducting cable heat insulating tube 100 includes an inner tube 110 and an outer tube 120 sleeved outside the inner tube 110, the inner tube 110 Between the vacuum interlayer 130 and the outer tube 120, an adsorption layer 200 is arranged in the vacuum interlayer 130, and an adsorption member 210 is arranged in the adsorption layer 200, and the adsorption member 210 is activated by heat;

[0034] The online activation structure of the adsorption part 210 includes: a heating body 300 disposed in the adsorption layer 200 and a coil 400 for wrapping outside the outer tube 120 , and the magnetic field generated by the coil 400 heats the heating body 300 .

[0035] In the present invention, the superconducting cable heat insulating tube 100 is loaded with an unactivated adsorbent 2...

Embodiment 2

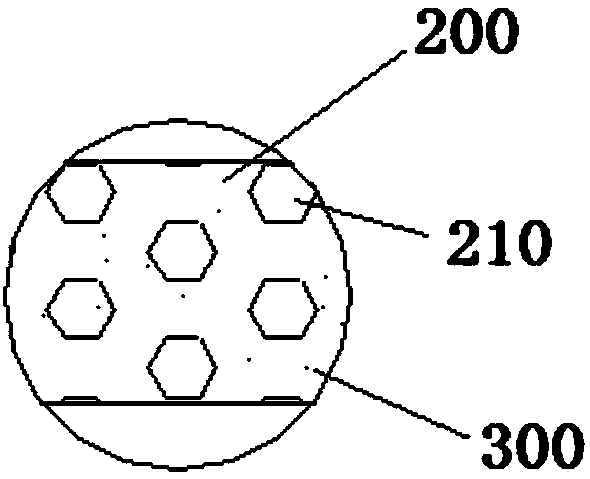

[0046] The difference between this embodiment and embodiment 1 is that, as figure 2 with image 3 As shown, the heating body is a plurality of powdery heating particles, and the plurality of powdery heating particles are evenly distributed in the adsorption member, which can also make the heating body 300 evenly heat the adsorption member 210 in the entire adsorption layer 200 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com