Energy-saving and environment-friendly size for cotton and man-made cellulose fibers and its application

An artificial cellulose, energy-saving and environmental-friendly technology, applied in fiber type, plant fiber, fiber treatment, etc., to achieve stable viscosity, reduce energy consumption, and clean weaving environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

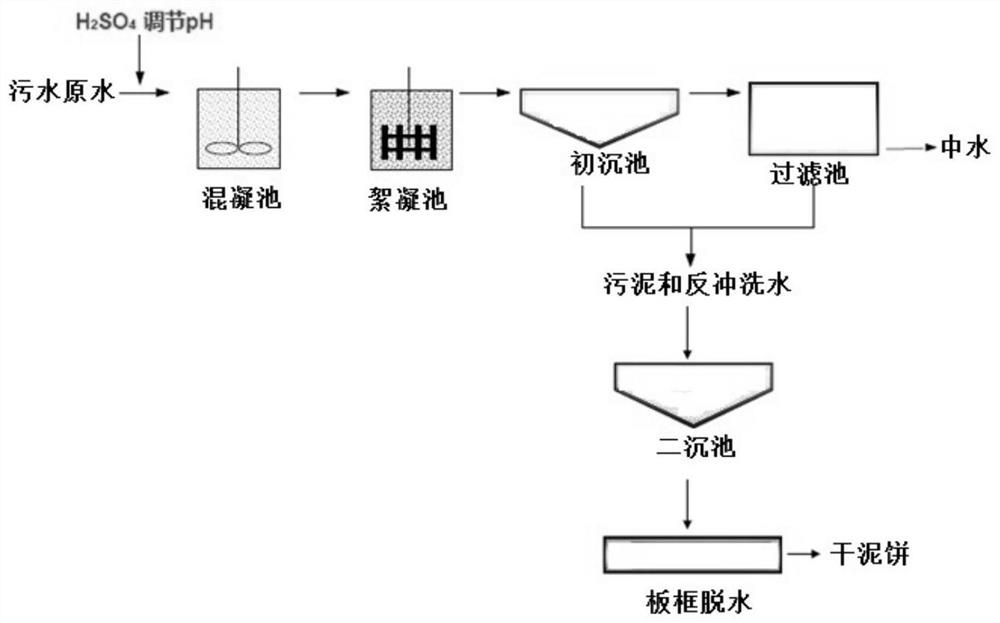

Method used

Image

Examples

Embodiment

[0051] An energy-saving and environment-friendly slurry for cotton and man-made cellulose fibers. The main components are Fluorine / Serra, wax and water.

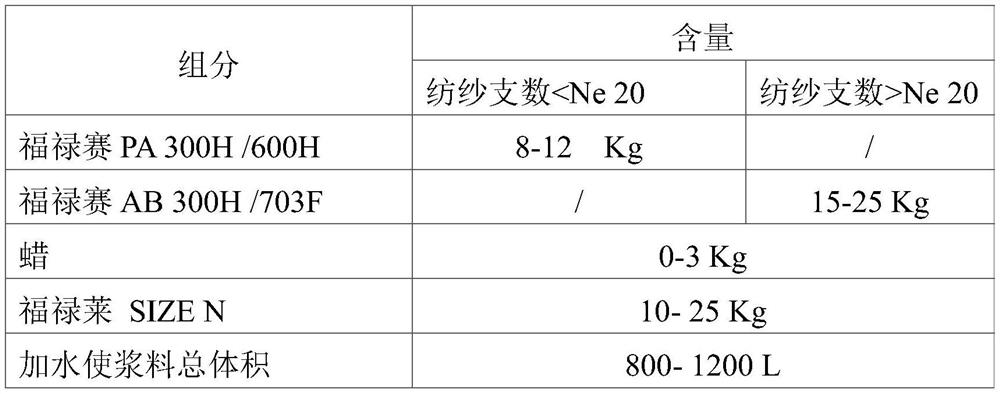

[0052] When the size is PVA-free, starch-free, fully substituted formula, as shown in Table 1.

[0053] Table 1

[0054]

[0055] According to different yarn counts, the total warp number is constant.

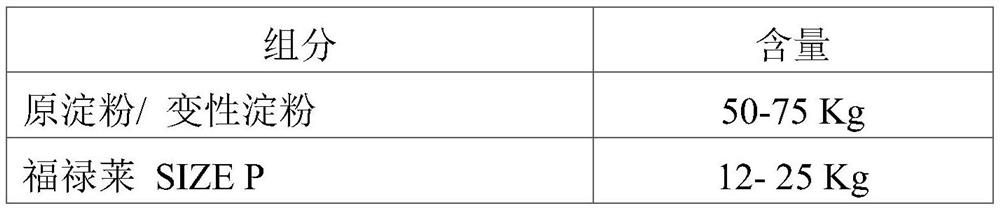

[0056] When the slurry is PVA-free, semi-substituted formula, as shown in Table 2.

[0057] Table 2

[0058]

[0059]

[0060] According to different yarn counts, the total warp number is constant.

[0061] Wherein, the starch is selected from native starch or modified starch (such as CMS modified starch). The wax is emulsified oil-1.

[0062] The application of the above-mentioned energy-saving and environment-friendly size is applied to the sizing process. The sizing process includes the sizing process and the desizing process; Sizing, after injecting into the size tank, the method of single size tank sizing;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com