Air heating furnace cooling water supply system and control method

A technology of water supply system and control method, which is applied in the field of iron and steel metallurgy, and can solve the problems that the cooling water of the hot blast stove cannot be operated independently, and the independent water supply of cooling equipment cannot be realized, so as to save time and increase the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

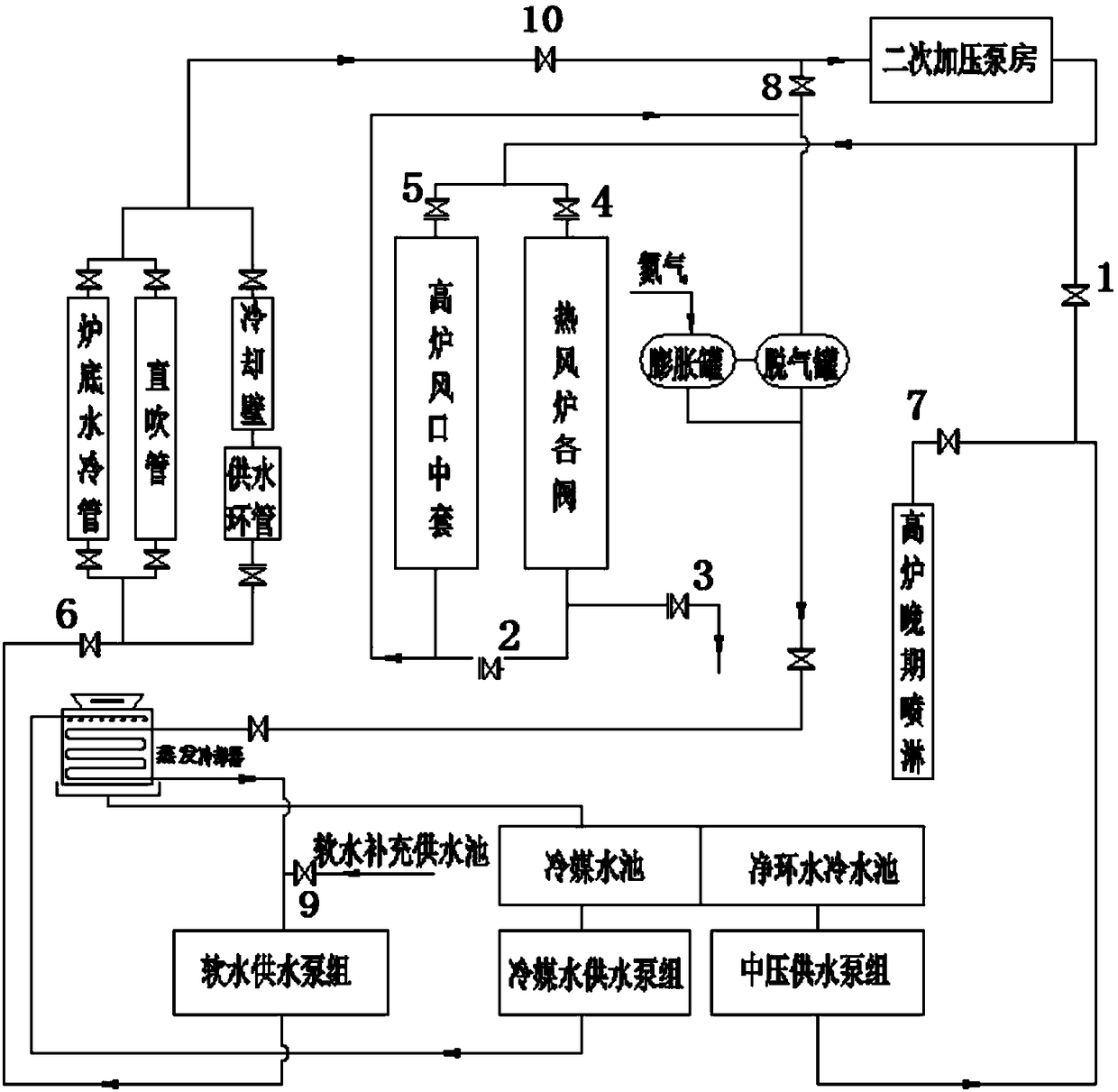

[0033] Such as figure 1 As shown, the hot blast stove cooling water supply system of this embodiment includes several hot blast stove valves, medium pressure water supply pump sets and a secondary pressurization pump room, and is characterized in that: the soft water pipeline output by the secondary pressurization pump room is set The switch valve I1 and the connecting pipe connect the soft water pipe output from the secondary pressurization pump room with the medium pressure water pipe output from the medium pressure water supply pump unit; the connected soft water pipe branches into the valves of the hot blast stove and the middle sleeve of the blast furnace tuyere. The on-off valve IV4 is set at the water inlet pipe of each valve of the hot blast stove, and the on-off valve V5 is set at the water inlet pipe in the tuyere of the blast furnace; a three-way pipe is set on the soft water pipe output from each valve of the hot blast stove, and the three-way pipe includes the inle...

Embodiment 2

[0037] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the soft water pipeline containing the on-off valve II2 is connected in parallel with the outlet water pipe in the tuyere of the blast furnace and then connected in series, and then divided into two paths, one path enters the evaporative cooler through the degassing tank , the switch valve Ⅷ8 is set on the other soft water pipeline, and then input to the secondary pressurization pump room; the degassing tank is connected with the expansion tank, and nitrogen gas is introduced into the expansion tank, and the degassing tank and the evaporative cooler At least one switch valve is arranged on the soft water pipeline.

[0038] In this embodiment, the switching valve II is a DN250 valve.

[0039] In this embodiment, nitrogen gas is charged into the expansion tank to detect whether the soft water pipeline is filled with soft water; the switch valve provided on the return water pipel...

Embodiment 3

[0041] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 2. Preferably, the soft water pipeline output by the evaporative cooler is connected to the soft water supply pump set, and the soft water pipeline between the evaporative cooler and the soft water supply pump set is supplemented with soft water The pipeline is connected, and the soft water supply pipeline is connected with the soft water supply pool; the switch valve Ⅸ9 is set on the soft water supply pipeline; the branch pipe of the evaporative cooler is connected with the refrigerant pool, and the refrigerant water pool is connected with a refrigerant water supply pump group, and a refrigerant water supply pump group The water in the refrigerant pool is supplied to the evaporative cooler.

[0042] In this embodiment, the soft water replenishment water supply pool provides soft water for the blast furnace, and the refrigerant pool is used for cooling by the evaporative cooler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com