Production method of rice starch with enhanced cold water solubility and resistance

A technology of anti-digestion rice and a production method, applied in the field of food processing, can solve problems such as starch digestibility without considering cold water solubility, and achieve the effects of enhancing cold water solubility, promoting peristalsis, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 20 parts by weight of xanthan gum in 11,000 parts by weight of water to obtain a uniform xanthan gum solution, add 300 parts by weight of rice starch to the xanthan gum solution, mix well, and completely gelatinize in a water bath at 95°C for 28 minutes, room temperature at 25°C Leave to cool for 12 hours; pump the cooled starch paste into a spray dryer at a pump flow rate of 10% and a feed temperature of 200°C, and dry to obtain a finished product. Determination of the solubility, swelling power and digestibility of starch.

[0023] Using the above-mentioned method for measuring solubility, swelling power and digestibility, the results of measuring the solubility, swelling power and digestibility of the sample and the control sample without adding xanthan gum are shown in Table 1.

[0024] Table 1.

[0025]

[0026] It can be seen from the results that this production method can significantly enhance the cold water solubility and swelling power of starch; ...

Embodiment 2

[0028] Dissolve 20 parts by weight of carrageenan in 11,000 parts by weight of water to obtain a homogeneous carrageenan solution, add 400 parts by weight of rice starch to the carrageenan solution, mix well and completely gelatinize in a water bath at 96°C for 30 minutes, and place it at room temperature at 25°C for cooling for 11 h; pump the cooled starch paste into a spray dryer at a pump flow rate of 8% and a feed temperature of 200°C, and dry to obtain a finished product. Determination of solubility, swelling power and digestibility of pregelatinized starch.

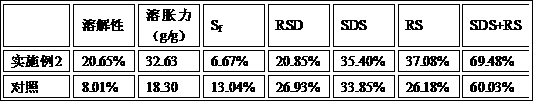

[0029] Using the above-mentioned method for measuring solubility, swelling power and digestibility, the results of measuring the solubility, swelling power and digestibility of the sample and the control sample without adding carrageenan are shown in Table 2.

[0030] Table 2.

[0031]

[0032] It can be seen from the results that the production method can significantly enhance the cold water solubility and swel...

Embodiment 3

[0034] Dissolve 25 parts by weight of sodium alginate in 10,000 parts by weight of water to obtain a uniform sodium alginate solution, add 400 parts by weight of rice starch to the sodium alginate solution, mix well, and completely gelatinize in a water bath at 96 °C for 30 minutes, room temperature 25 °C Leave to cool for 11 hours; pump the cooled starch paste into a spray dryer at a pump flow rate of 8% and a feed temperature of 200 °C, and dry to obtain a finished product. Determination of solubility, swelling power and digestibility of pregelatinized starch.

[0035] Using the above-mentioned method for measuring solubility, swelling power and digestibility, the results of measuring the solubility, swelling power and digestibility of the sample and the control sample without adding sodium alginate are shown in Table 3:

[0036] table 3.

[0037] .

[0038] It can be seen from the results that this production method can significantly enhance the cold water solubility an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com