Preparation method of photosensitive resin with flame retardancy and application of photosensitive resin on circuit board

A photosensitive resin, flame retardant technology, applied in the application field of photosensitive ink on circuit boards, can solve the problems of non-flame retardant, poor flexibility, poor chemical resistance of covering materials, etc., to achieve good chemical resistance, Good bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

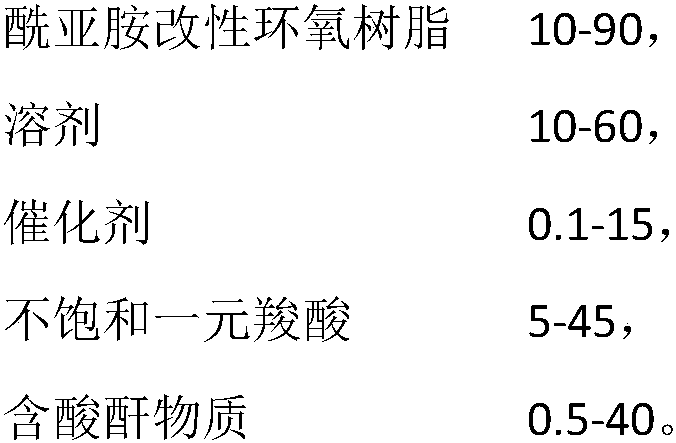

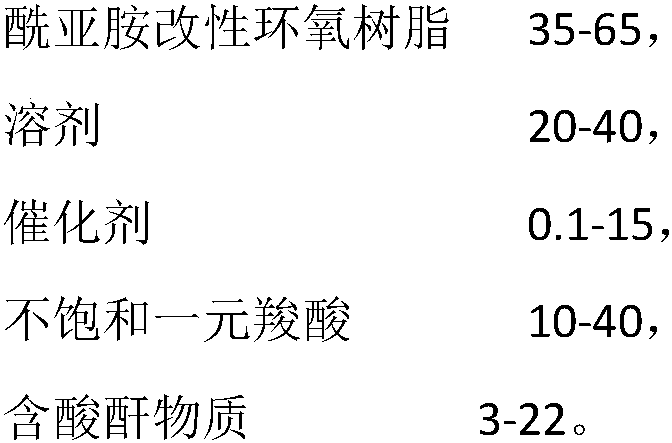

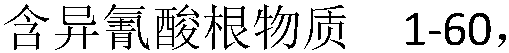

Method used

Image

Examples

Embodiment 1

[0042] Pour 40 grams of solvent γ-butyrolactone into a three-necked flask, add 26 grams of IPDI and 15.2 grams of tetrahydrophthalic anhydride, slowly heat to 150°C, react for 2 hours, then add 80 grams of novolac epoxy resin, and react at 150°C After 4 hours, imide-modified epoxy resin 1 was obtained.

[0043] Add 20 grams of solvent γ-butyrolactone, 25 grams of unsaturated monocarboxylic acid acrylic acid, and 1 gram of catalyst triphenylphosphine to 160 grams of the above-mentioned imide-modified epoxy resin 1, and heat to 100-120 ° C for 8 hours Afterwards, 25 grams of tetrahydrophthalic anhydride, an acid anhydride-containing substance, was added, and heated to 100-120° C. for 5 hours to obtain photosensitive resin 1 with flame-retardant properties.

Embodiment 2

[0045] Pour 40 grams of diethylene glycol ethyl ether acetate into a three-necked flask, add 96 grams of TDI, 20 grams of alkenyl succinic anhydride, slowly heat to 200 ° C, react for 6 hours, and then add 4,5-epoxycyclohexane 70 g of diglycidyl alkane-1,2-dicarboxylate was reacted at 200°C for 8 hours to obtain imide-modified epoxy resin 2.

[0046] Add 40 grams of solvent diethylene glycol ethyl ether acetate, 40 grams of crotonic acid, and 10 grams of triethylamine to 200 grams of the above-mentioned imide-modified epoxy resin 2, heat to 120-140 ° C for 2 hours and then add olefin 40 grams of succinic anhydride was heated to 120-140° C. for 3 hours to obtain photosensitive resin 2 with flame retardancy.

Embodiment 3

[0048] Pour 50 grams of dimethylpropionamide into a three-necked flask, add 50 grams of MDI, 30 grams of glutaric anhydride, slowly heat to 250 ° C, react for 2 hours, then add N, N-glycidyl-2,4, 80 g of 6-tribromoaniline was reacted at 200°C for 3 hours to obtain imide-modified epoxy resin 3.

[0049] Add 150 grams of solvent dimethylpropionamide, 120 grams of 5-hexenoic acid, and 90 grams of N,N-dimethylethanolamine to 210 grams of the above-mentioned imide-modified epoxy resin 2, and heat to 70-90 ° C for reaction After 10 hours, 90 grams of glutaric anhydride was added, heated to 70-90° C. and reacted for 9 hours to obtain photosensitive resin 3 with flame retardancy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com