Preparation method of low-wear-type ceramic-based composite bake material

A ceramic-based composite and brake material technology, which is applied to mechanical equipment, friction linings, gear transmission mechanisms, etc., can solve the problems of low friction coefficient, high wear rate, and attenuation of braking performance, so as to improve thermal conductivity and wear resistance Effect of improving performance and coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

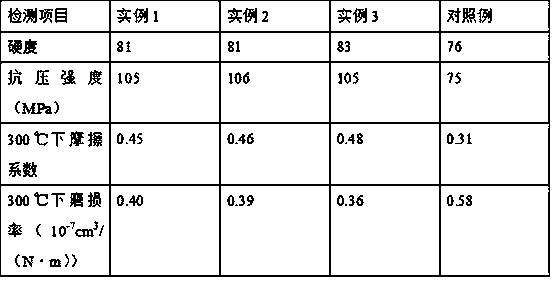

Examples

example 1

[0025] Weigh the elephant ear sponge and cut it into a sponge block with a size of 20cm×10cm, rinse it with absolute ethanol and deionized water three times in sequence to obtain the washed sponge block, then weigh the moso bamboo, and split the moso bamboo with a bamboo knife to grow Moso bamboo green bamboo shoots with a thickness of 20 cm are immersed in a sodium hydroxide solution with a concentration of 1mol / L, heated and boiled for 1 hour, and then air-dried naturally to obtain pretreated green bamboo shoots; the pretreated green bamboo shoots are repeatedly rolled with stone rollers for 20 minutes, Manually extract the bamboo fiber bundles, spread the above-mentioned cleaned sponge blocks, and then lay the bamboo fiber bundles on the sponge blocks in a disorderly manner, and control the laying thickness of the bamboo fiber bundles to be 4mm. The same sponge block is stacked on the fiber bundle layer, and the layer of bamboo fiber bundle layer is stacked in the order of o...

example 2

[0027]Weigh the elephant ear sponge and cut it into a sponge block with a size of 20cm×10cm, wash it with absolute ethanol and deionized water four times in sequence to obtain the washed sponge block, then weigh the moso bamboo, and use a bamboo knife to split the moso bamboo into growth Moso bamboo green bamboo shoots with a thickness of 25 cm were immersed in a sodium hydroxide solution with a concentration of 1mol / L, heated and boiled for 2 hours, and then dried naturally to obtain pretreated green bamboo shoots; the pretreated green bamboo shoots were repeatedly rolled with stone rollers for 25 minutes, Manually extract the bamboo fiber bundles, spread the above-mentioned cleaned sponge blocks, and then lay the bamboo fiber bundles on the sponge blocks in a disorderly manner, and control the laying thickness of the bamboo fiber bundles to be 4mm. A layer of same sponge block is stacked on the fiber bundle layer, and the sequence of one layer of sponge block and one layer of...

example 3

[0029] Weigh the elephant ear sponge and cut it into a sponge block with a size of 20cm×10cm, rinse it with absolute ethanol and deionized water for 5 times in sequence to obtain the washed sponge block, then weigh the moso bamboo, and split the moso bamboo with a bamboo knife to grow Moso bamboo green bamboo shoots with a thickness of 30 cm were immersed in a sodium hydroxide solution with a concentration of 1mol / L, heated and boiled for 3 hours, and then dried naturally to obtain pretreated green bamboo shoots; the pretreated green bamboo shoots were repeatedly rolled with stone rollers for 30 minutes, Manually extract the bamboo fiber bundles, spread the above-mentioned cleaned sponge blocks, and then lay the bamboo fiber bundles on the sponge blocks in a disorderly manner, and control the laying thickness of the bamboo fiber bundles to be 5mm. A layer of same sponge block is stacked on the fiber bundle layer, and the sequence of one layer of sponge block and one layer of ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com