Shielding device for high-reflective material and application of device

A shielding device and high-radiation technology, which is applied in the field of shielding devices for high-radiation materials and γ-ray shielding devices, can solve the problems of strong radiation hazards, surrounding environment and operator injury, etc., and achieve good shielding effect and good shielding protection effect, process continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

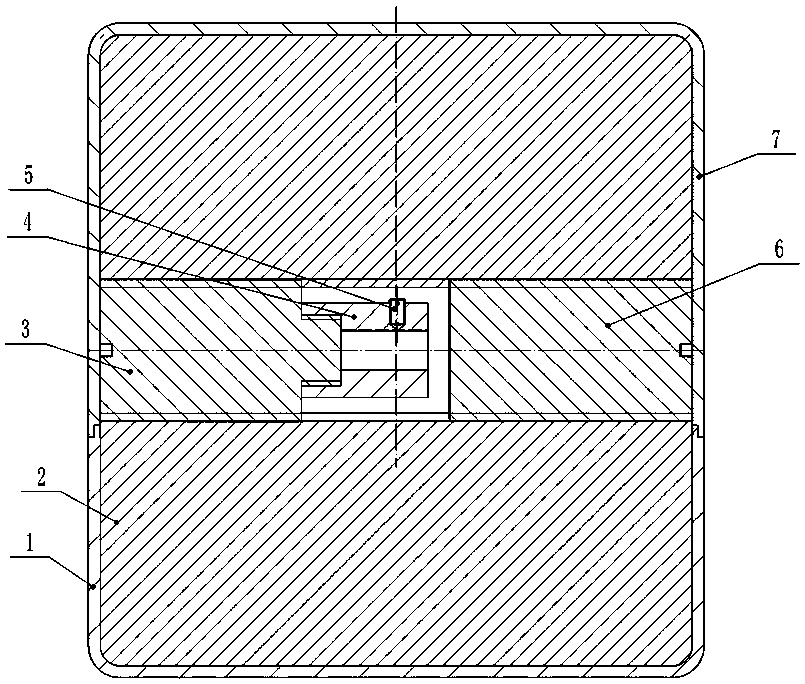

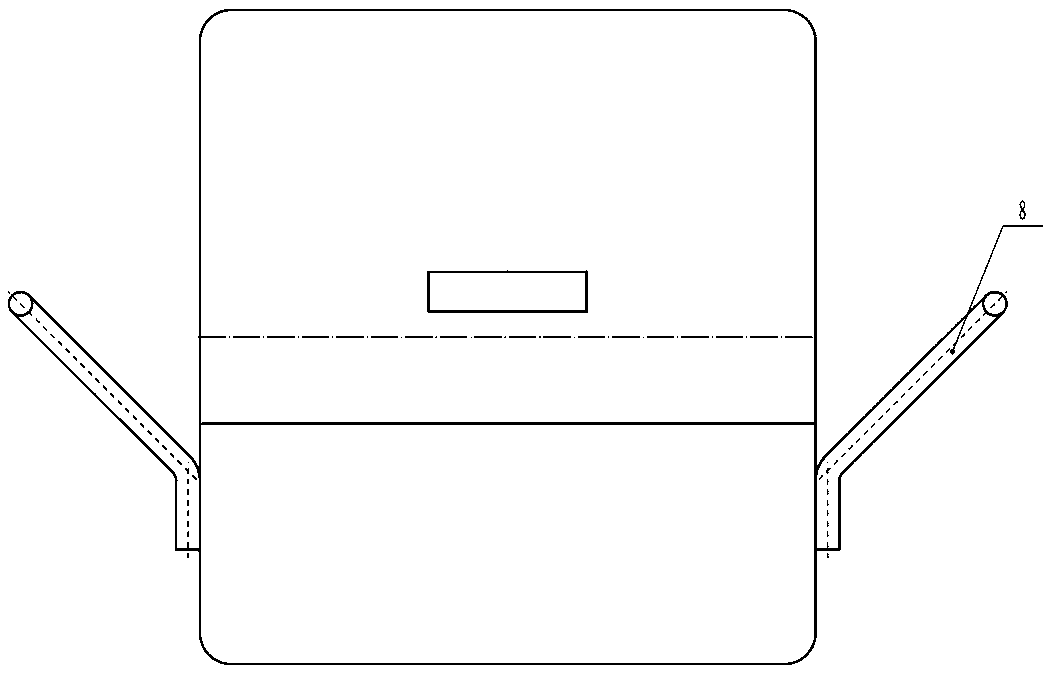

Method used

Image

Examples

Embodiment 1

[0069] The shielding sample is a steel ingot processed by a civil nuclear reactor, and its dimensions are 27.5mm×10mm×10mm (length×width×height).

[0070] The dose equivalent rate on the surface is as high as 2247.48mSv / h without shielding. Using the device and method of this embodiment, the RPV steel sample is fixed inside the shielding cavity, and the second stud is screwed to reach the designated position to realize the shielding cavity The radiation dose is detected near the second stud on the surface of the shielded cavity. The test results showed that the gamma-ray dose equivalent rate was 29.0μSv / h, and no beta-ray was detected.

[0071] Close the lid, and test the radiation dose in the axial direction of the second stud. The test results show that no β-rays are detected, and the dose equivalent rates of γ-rays are 17.2μSv / h and 19.5μSv / h, respectively. The result meets the limit value of the radiation level on the surface of packages and means of transport in GB11806-...

Embodiment 2

[0073] The highly radioactive RPV steel samples were machined, and the target size was 10mm×10mm×0.8mm (length×width×height).

[0074] Open the barrel cover, unscrew and withdraw the second stud, and perform radiation dose rate detection at a position 0 cm away from the surface of the shielding cavity in the normal direction of the second stud. The test results showed that the dose equivalent rate of gamma rays was 1.55mSv / h, and no beta rays were detected.

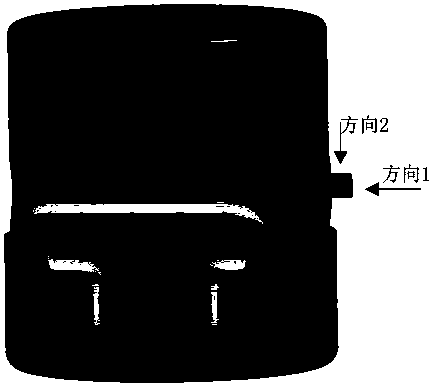

[0075] Screw the first stud until 1cm is exposed at the front end of the RPV steel sample, that is, the processing position is reached. like image 3 As shown, in direction 1, the radiation dose rate detection is carried out on the surface of the RPV steel sample, and the test results show that the β-ray dose equivalent rate is 4.6mSv / h, and the gamma-ray dose equivalent rate is 6.0mSv / h.

[0076] In direction 2, the radiation dose rate detection was carried out on the surface of the RPV steel sample, and the test resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com