Modular area cooling system

A cooling system and modular technology, applied in the field of modular district cooling system, can solve the problems of urban construction and environmental impact, need to be placed on the roof of other buildings, increase the energy consumption of cooling water pump transportation, etc., so as to reduce the transmission of pipe network. Energy consumption and cooling loss, optimizing equipment layout and pipelines, and improving the effect of main engine operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

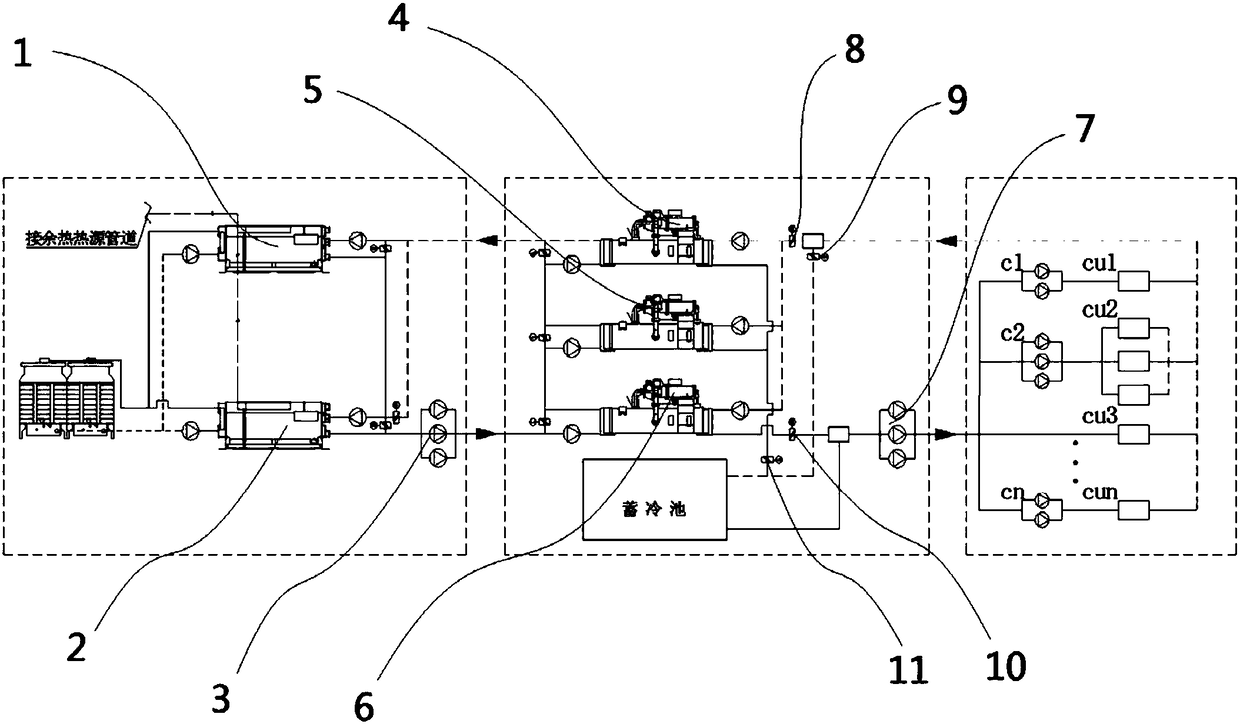

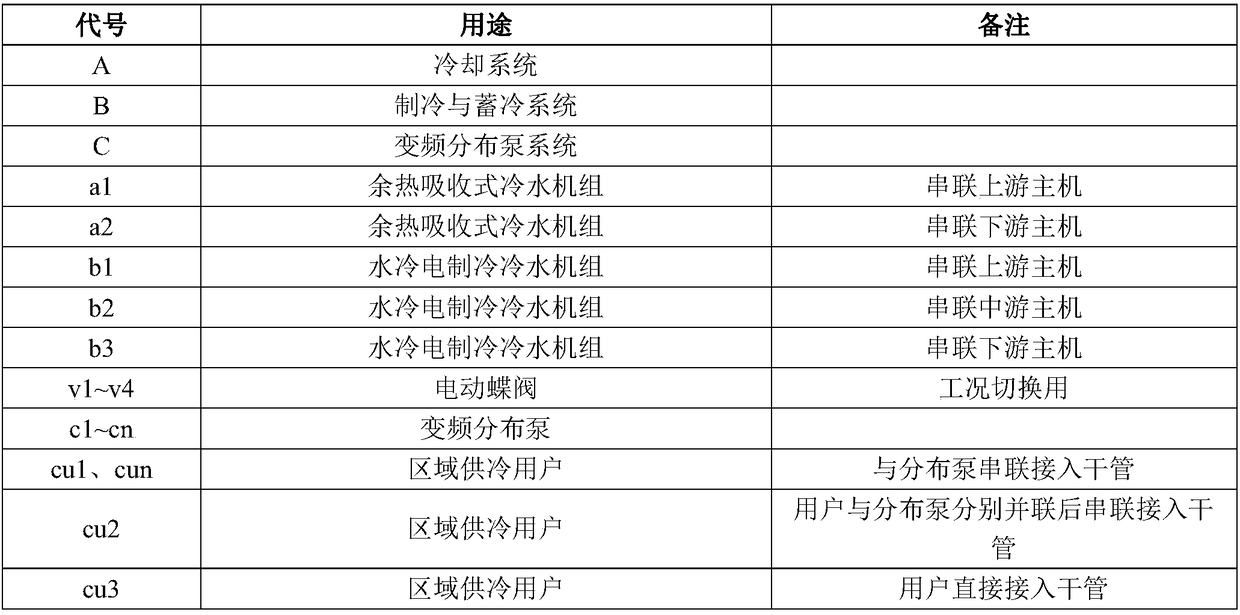

[0028] Such as figure 1 , a modular district cooling system, including a cooling system A, a refrigeration and cold storage system B, and a variable frequency distribution pump system C, wherein

[0029] The cooling system includes waste heat source pipeline, waste heat absorption chiller a1, cooling system waste heat absorption chiller a2, cooling water delivery pump BQ; among them, the waste heat heat source pipeline transports waste heat to drive the waste heat absorption chiller a1 running in series, and the cooling system waste heat absorption Type chiller a2, cooling the cooling return water to obtain low-temperature cooling water, and the low-temperature cooling water is transported to the refrigeration and cold storage system through the cooling water delivery pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com