Hydroxypropyl tapioca starch-zein compound and preparation method thereof

A technology of zein and hydroxypropyl cassava, which is applied in the field of grain processing to achieve the effects of convenient processing, industrial production and increased contact opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

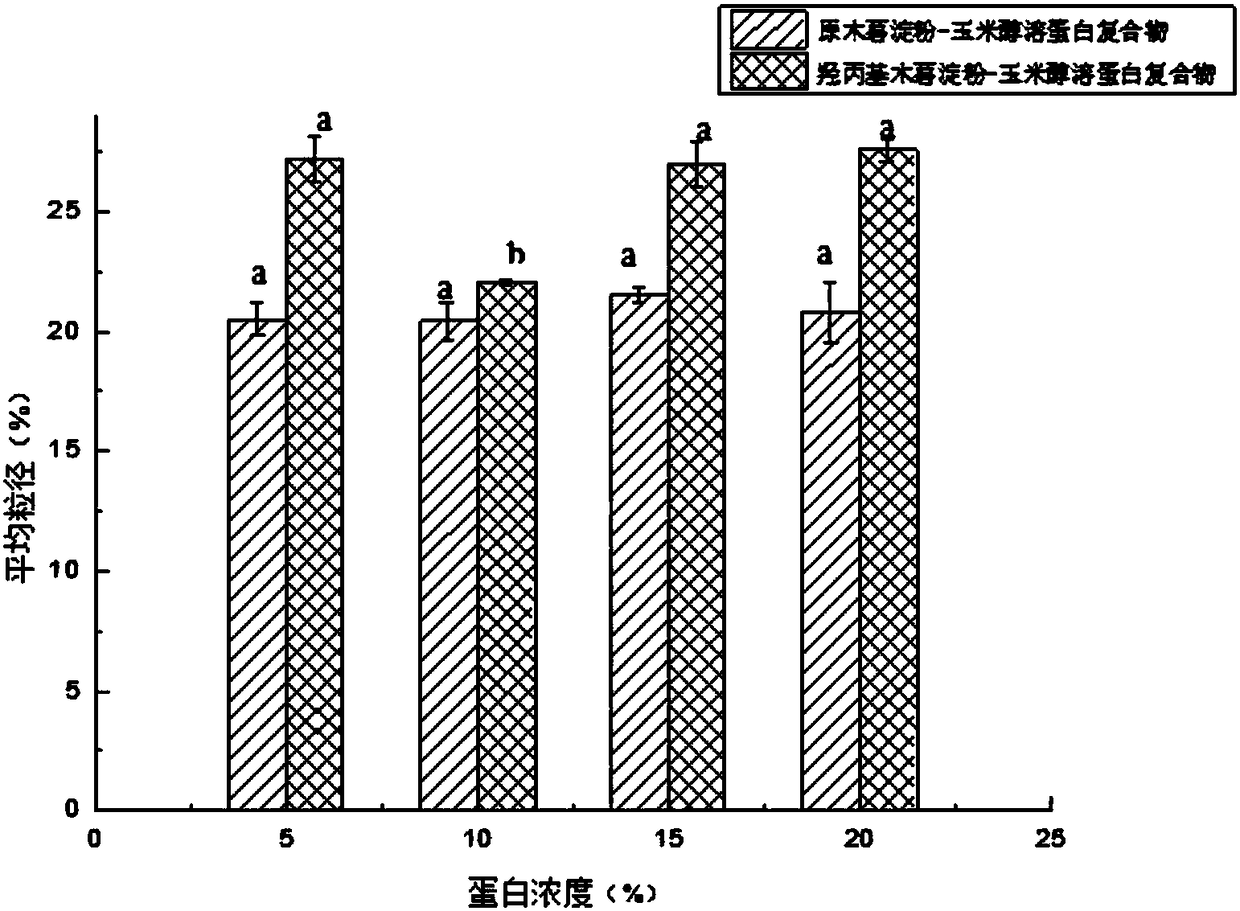

[0054] A preparation method of hydroxypropyl tapioca-zein complex, comprising the following steps:

[0055] (1) Dissolving zein in 70% (v / v) ethanol solution to prepare zein solutions with mass concentrations of 5%, 10%, 15%, and 20% respectively;

[0056] (2) Add hydroxypropyl tapioca starch to the zein solution (the weight ratio of hydroxypropyl tapioca starch and zein is 2:1), adjust the pH to 9, and mix in a constant temperature water bath at 40°C for 1 hour, After mixing, slowly add into cold water at 0°C, the amount of cold water is 80 times the weight of zein, after stirring, vacuum filter, dry at 45°C, pass through 80-mesh sieve to obtain.

[0057] Using the same method, the tapioca starch-zein complex was prepared using unmodified tapioca starch as a control.

Embodiment 2

[0059] A preparation method of hydroxypropyl tapioca-zein complex, comprising the following steps:

[0060] (1) dissolving zein in 70% (v / v) ethanol solution to prepare a zein solution with a mass concentration of 5%;

[0061] (2) Add hydroxypropyl tapioca starch to the zein solution (the weight ratio of hydroxypropyl tapioca starch and zein is 2:1, 4:1, 6:1, 8:1 respectively), adjust pH to 9, mixed in a constant temperature water bath at 40°C for 1 hour, slowly added to cold water at 0°C after mixing, the amount of cold water was 80 times the weight of zein, after stirring, vacuum filtered, dried at 45°C, Pass through a 80-mesh sieve.

[0062] Using the same method, the tapioca starch-zein complex was prepared using unmodified tapioca starch as a control.

Embodiment 3

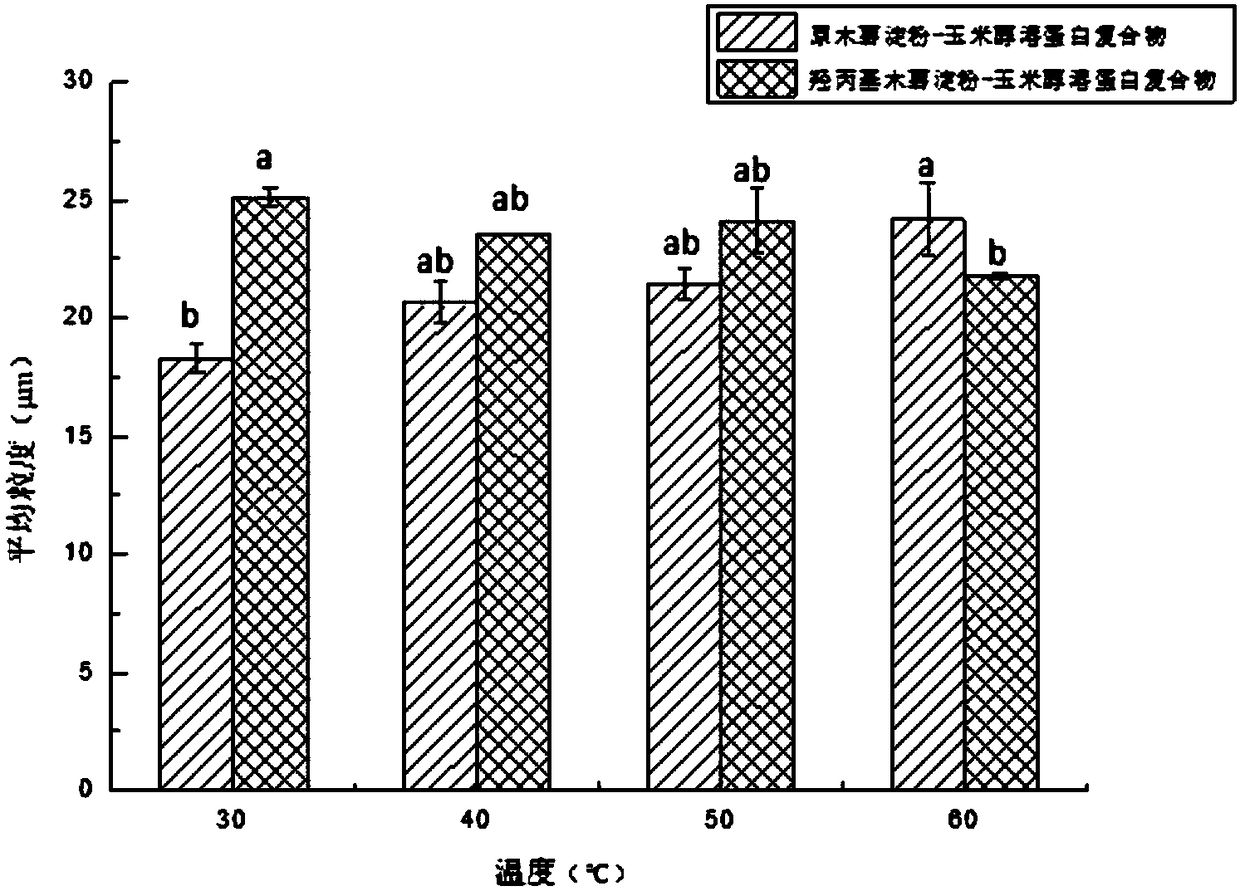

[0064] A preparation method of hydroxypropyl tapioca-zein complex, comprising the following steps:

[0065] (1) dissolving zein in 70% (v / v) ethanol solution to prepare a zein solution with a mass concentration of 10%;

[0066] (2) Add hydroxypropyl tapioca starch to the zein solution (the weight ratio of hydroxypropyl tapioca starch and zein is 2:1), adjust the pH to 9, and heat at 30°C, 40°C, and 50°C respectively , Mix in a constant temperature water bath at 60°C for 1 hour, slowly add to cold water at 0°C after mixing, the amount of cold water is 80 times the weight of zein, after stirring, vacuum filter, dry at 45°C, and pass through a 80-mesh sieve , that is.

[0067] Using the same method, the tapioca starch-zein complex was prepared using unmodified tapioca starch as a control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com