Device for removing dust on papers before printing of printed matters

A dust removal device and printed matter technology, which is applied in the direction of removing dust, brushes, bristles, etc., can solve the problems of increasing the scrapping rate of printed matter, white spots of printed matter, etc., and achieve the effect of improving dust removal rate, moderate mechanical properties, and ensuring printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

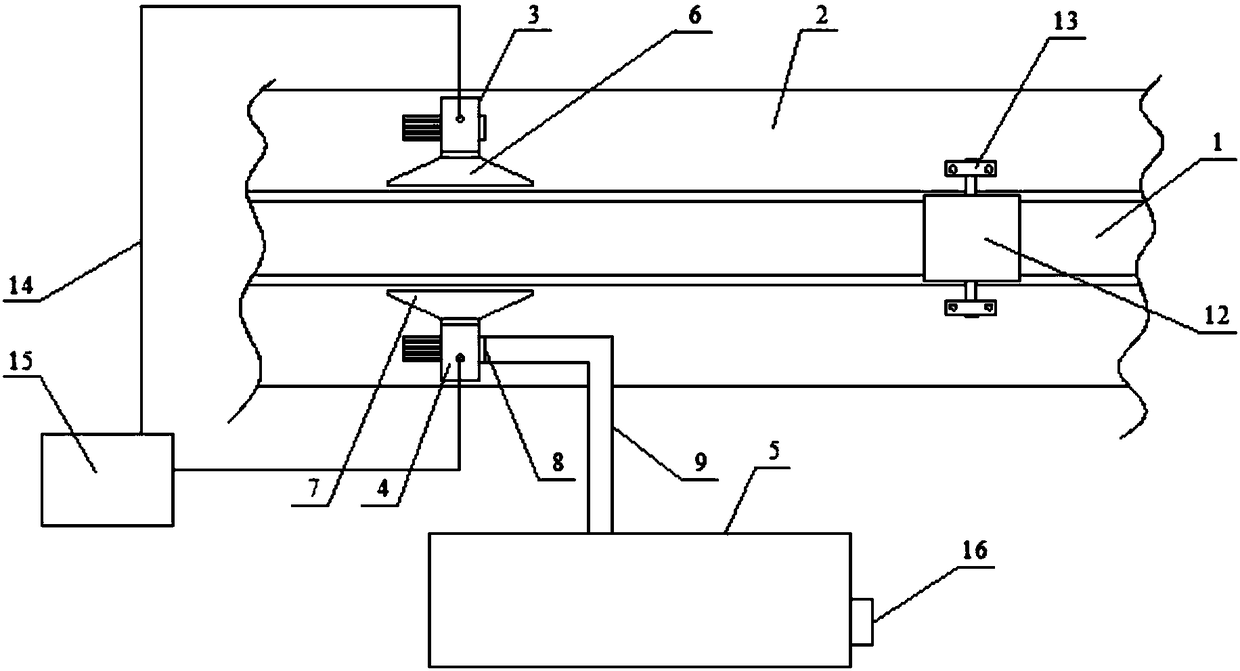

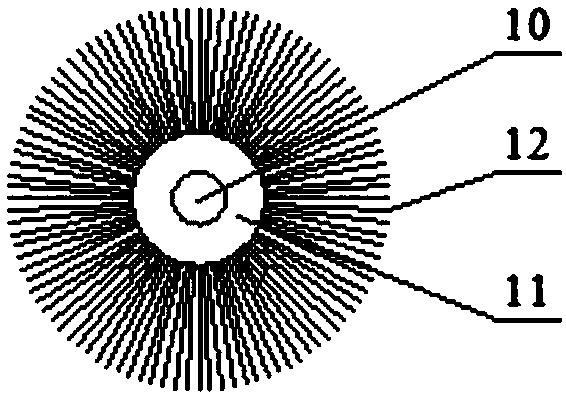

[0023] Such as figure 1 and figure 2 As shown in the figure, a paper dust removal device before printing, including a paper transfer platform 1, a first-level dust removal mechanism, a second-level dust removal mechanism and a dust removal mechanism installation platform 2, the dust removal mechanism installation platform is symmetrically arranged on both sides of the paper delivery platform, and the first-level dust removal mechanism The dust removal mechanism is composed of a positive pressure blower 3, a negative pressure induced draft fan 4 and a settling chamber 5. The positive pressure blower is provided with a trumpet-shaped air outlet 6, and the negative pressure induced draft fan is provided with a trumpet-shaped air inlet 7. The trumpet-shaped air outlet and the horn The shape air inlets are all facing the upper surface of the paper, the negative pressure induced draft fan air outlet 8 is connected with the settling chamber through the air supply pipe 9, and the sec...

Embodiment 2

[0025] Such as figure 1 and figure 2 As shown in the figure, a paper dust removal device before printing, including a paper transfer platform 1, a first-level dust removal mechanism, a second-level dust removal mechanism and a dust removal mechanism installation platform 2, the dust removal mechanism installation platform is symmetrically arranged on both sides of the paper delivery platform, and the first-level dust removal mechanism The dust removal mechanism is composed of a positive pressure blower 3, a negative pressure induced draft fan 4 and a settling chamber 5. The positive pressure blower is provided with a trumpet-shaped air outlet 6, and the negative pressure induced draft fan is provided with a trumpet-shaped air inlet 7. The trumpet-shaped air outlet and the horn The shape air inlets are all facing the upper surface of the paper, the negative pressure induced draft fan air outlet 8 is connected with the settling chamber through the air supply pipe 9, and the sec...

Embodiment 3

[0027] Such as figure 1 and figure 2 As shown in the figure, a paper dust removal device before printing, including a paper transfer platform 1, a first-level dust removal mechanism, a second-level dust removal mechanism and a dust removal mechanism installation platform 2, the dust removal mechanism installation platform is symmetrically arranged on both sides of the paper delivery platform, and the first-level dust removal mechanism The dust removal mechanism is composed of a positive pressure blower 3, a negative pressure induced draft fan 4 and a settling chamber 5. The positive pressure blower is provided with a trumpet-shaped air outlet 6, and the negative pressure induced draft fan is provided with a trumpet-shaped air inlet 7. The trumpet-shaped air outlet and the horn The shape air inlets are all facing the upper surface of the paper, the negative pressure induced draft fan air outlet 8 is connected with the settling chamber through the air supply pipe 9, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com