Kaolin composite adsorption material and its preparation method and application

A composite adsorption material, kaolin technology, applied in the field of water treatment agent and its preparation, can solve the problems of immature research and development of advanced oxidative degradation technology, poor applicability, need to be improved, etc., to improve adsorption capacity, improve adsorption efficiency, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

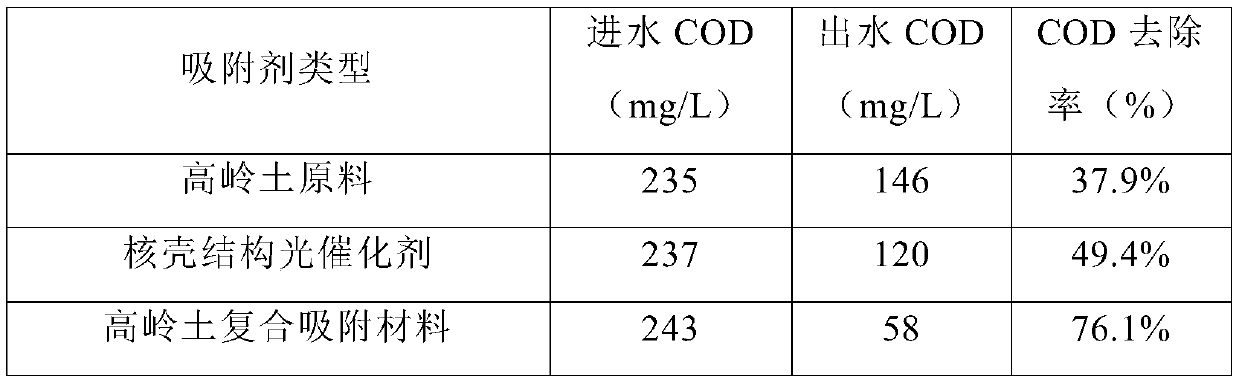

Examples

Embodiment 1

[0023] This embodiment provides a kaolin composite adsorption material, which includes kaolin and chitosan which forms an intercalation structure with the kaolin, the chitosan is loaded with a core-shell structure photocatalyst, and the core-shell structure photocatalyst includes a particle size of 50-100 nm parts of tin dioxide nano-core and a porous carbon shell coated on the surface of the tin dioxide nano-core, the porous carbon shell includes a plurality of micropores with a pore diameter of 20-50 nm; the porosity of the porous carbon shell is 30%, the specific surface area of the core-shell structure photocatalyst is 300m 2 / g; wherein, in the kaolin composite adsorption material, the chitosan content is 4% of the kaolin mass, and the tin dioxide nanoparticle content is 40% of the chitosan mass.

[0024] The present embodiment also provides a preparation method of the above-mentioned kaolin composite adsorption material, which includes the following steps:

[0025] St...

Embodiment 2

[0030] This embodiment provides a kaolin composite adsorption material. The structure of the composite adsorption material is basically the same as that of the composite adsorption material provided in Example 1. The difference is that the photocatalyst with a core-shell structure includes a Tin dioxide nano-core and the porous carbon shell coated on the surface of the tin dioxide nano-core; the porosity of the porous carbon shell is 40%, and the specific surface area of the core-shell structure photocatalyst is 320m 2 / g; wherein, in the kaolin composite adsorption material, the chitosan content is 5% of the kaolin mass, and the tin dioxide nanoparticle content is 50% of the chitosan mass.

[0031] The preparation method of the above-mentioned kaolin composite adsorption material provided in this example is basically the same as the preparation method provided in Example 1, the main difference is that: in step 1 of this example, an aqueous ethanol solution with a volume conc...

Embodiment 3

[0033] This embodiment provides a kaolin composite adsorption material. The structure of the composite adsorption material is basically the same as that of the composite adsorption material provided in Example 1. The difference is that the core-shell structure photocatalyst comprises Tin dioxide nano-core and the porous carbon shell coated on the surface of the tin dioxide nano-core; the porosity of the porous carbon shell is 50%, and the specific surface area of the core-shell structure photocatalyst is 350m 2 / g; wherein, in the kaolin composite adsorption material, the chitosan content is 6% of the kaolin mass, and the tin dioxide nanoparticle content is 70% of the chitosan mass.

[0034] The preparation method of the above-mentioned kaolin composite adsorption material provided in this example is basically the same as the preparation method provided in Example 1, the main difference is that: in step 1 of this example, an aqueous ethanol solution with a volume concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com