Battery diaphragm and preparation method and application thereof

A diaphragm and lithium-ion battery technology, applied in the field of battery diaphragm and its preparation, can solve the problems of poor lyophilicity of synthetic fibers, loss of diaphragm strength, and easy falling off of filler particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

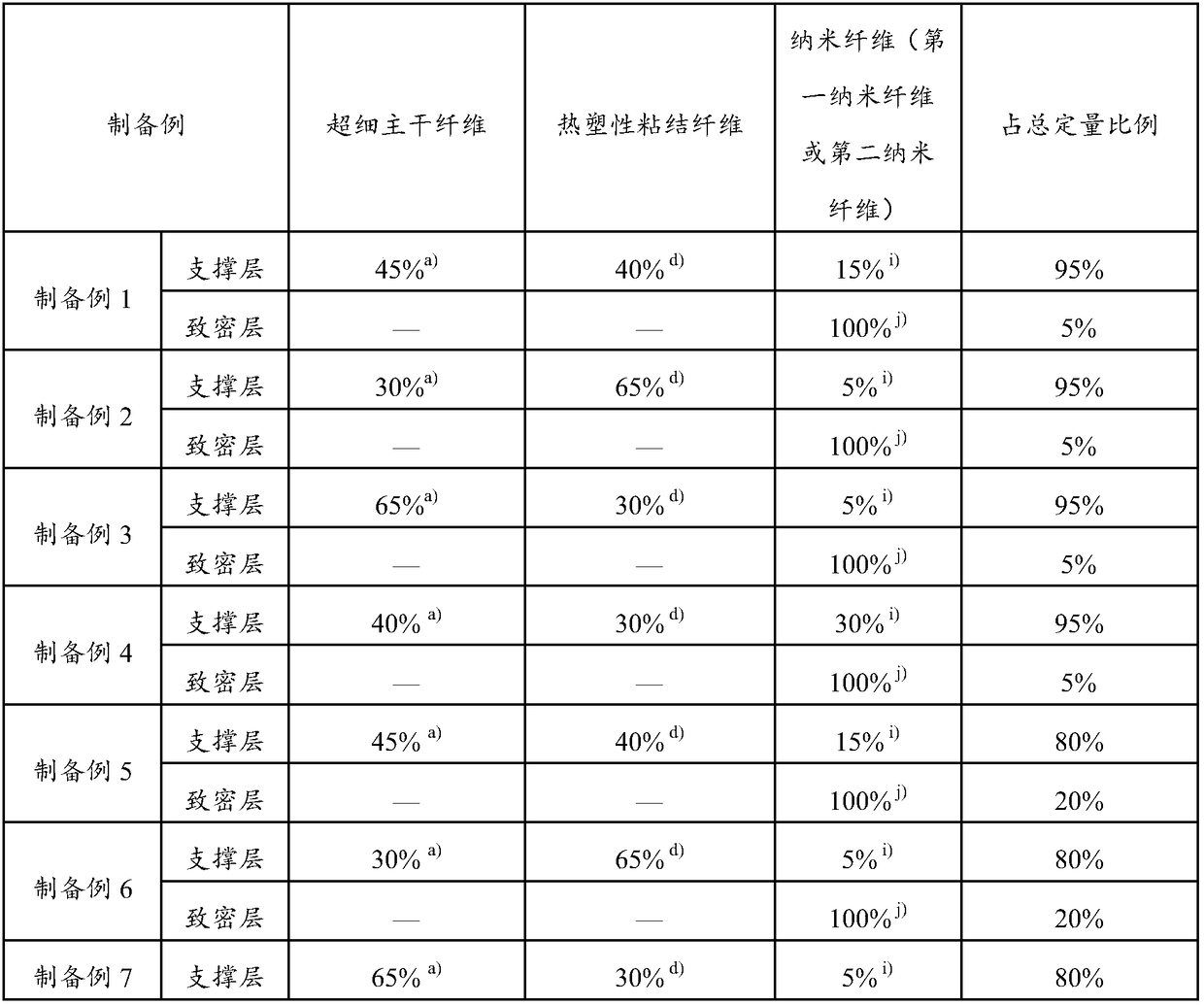

[0089] Preparation of lithium-ion battery separator substrate

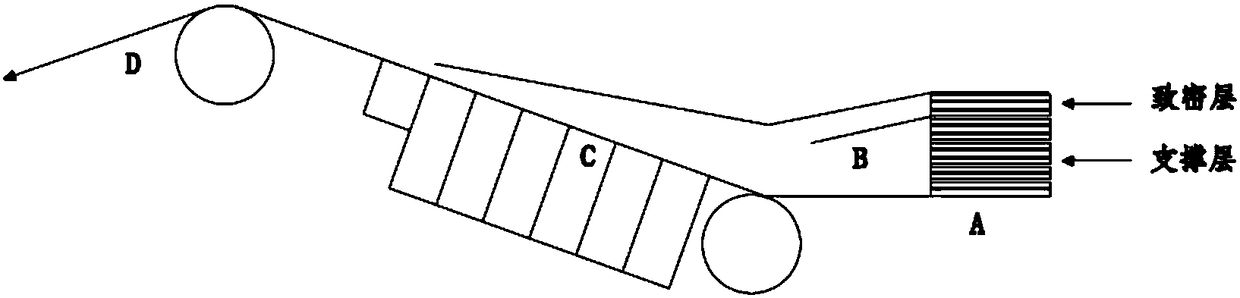

[0090] The following preparation examples 1-63 and comparative examples 1-11 only list the examples of using part of the fiber material to prepare the substrate, and other fiber materials and combinations thereof listed in the description of the present invention can also be used to prepare the substrate of the present invention; Wherein, the structure diagram of the Hydroformer double-layer hydraulic inclined wire former used in Preparation Example 1-63 of the present invention is as follows figure 2 shown.

preparation example 1

[0092] A lithium-ion battery diaphragm base material is composed of a support layer and a dense layer two-layer structure, and is prepared by the following method:

[0093] Step a: The support layer and the dense layer are mixed independently with water according to the formula shown in Table 1, deflagged, and beaten to a solid weight percentage concentration of 0.2wt%, and then the fibers of the support layer and the dense layer are respectively The raw materials are diluted with a slurry pump, wherein the fiber raw material of the support layer is diluted to a solid weight percent concentration of 0.02375wt% to obtain slurry 1; the dense layer fiber raw material is diluted to a solid weight percent concentration of 0.005wt% to obtain Slurry 2.

[0094] Step b: Slurry 1 and 2 obtained in step a are sent to the Hydroformer double-layer hydraulic inclined wire former, wherein slurry 1 enters the flow channel close to the forming wire, and the flow rate of the flow channel is 74...

preparation example 2-4、35-40、47、4

[0098] A lithium-ion battery separator base material is composed of a support layer and a dense layer with a two-layer structure. The formulations of the support layer and the dense layer are shown in Table 1, and the preparation method is the same as in Preparation Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com