A kind of elastic photosensitive resin for dlp 3D printing and preparation method thereof

A photosensitive resin and elastic technology, applied in the field of elastic photosensitive resin for DLP3D printing and its preparation, can solve the problem of difficult to meet market requirements, and achieve the effects of high molding precision, low product shrinkage, and low volatile odor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

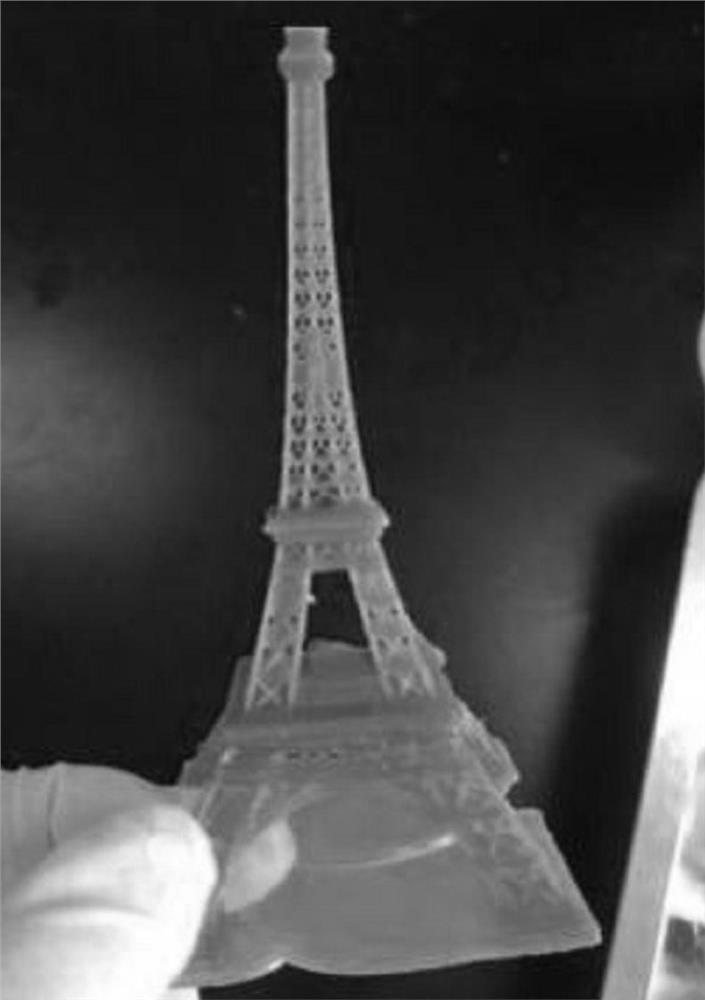

Image

Examples

Embodiment 1

[0029] In a 250 ml three flask, a bisphenol A epoxy resin was added, 10 grams of pure acrylate, 10 grams of 1,6-diol diacrylate, 17 grams of diethylene glycol diacrylate, 2, 4 , 6-trimethylbenzoyl-ethoxy-phenylphosphine oxide 3 grams, dispersant DP983 0.01 grams, 0.01 grams of benzene phenol, Deqian 431 0.01 grams, mixed under 50 ° C, stirred for 50min, The transparent uniform liquid; 0.5 grams of nano-titanium dioxide was added to the above-mentioned solution, and the mechanical stirring was 30 min to obtain a 3D printing elastic photosensitive resin.

[0030] The elastic photosensitive resin is placed in the DLP printer liquid slot, and the stretch pattern model is simulated in the computer. After the slice is completed, the underlying print is set to 20s, the underlying curing light is blue. The remaining layered cured light is white light, the exposure time is set to 8S, then by printing, the stretch pattern is obtained for mechanical performance test, the data is: the stretch...

Embodiment 2

[0032] In a 250 ml three-mouth flask, a bisphenol A epoxy acrylate was added, 15 grams of bisphenol A epoxy resin, 30 grams of polyethylene glycol acrylate, 25 grams of diethylene glycol diacrylate, biphenyloyloyl 3 grams, dispersant BYKP-105 0.01 grams, 0.01 grams of benzene phenol, Deqian 488 0.01 grams, mixed under 60 ° C, stirred for 60min, so that the transparent uniform liquid; in the above-mentioned solution, nano-dioxide 0.5 grams of silicon, mechanical stirring was 30 min to give 3D printing elastic photosensitive resin.

[0033]The elastic photosensitive resin resin is placed in a DLP printer liquid slot, and the stretch spline model is simulated in the computer. After the slice is completed, the underlying print is set to 15S, the underlying curing light is blue. The remaining layered cured light is white light, the exposure time is set to 6s, then by printing, the stretch pattern is obtained for mechanical performance test, the data is: Tensile modulus: 4530n / (mm 2 T...

Embodiment 3

[0035] In a 250 ml three-mouth flask, a difunctional aggregate polyurethane is added, 20 grams of polyacrylate, 20 grams of polyacrylate, 20 grams of cellyldiphenylene glycol diacrylate, diethylene glycol diacrylate 35 g, 2, 4, 6 - Trimethylbenzoyl-ethoxy-phenylphosphine 3 grams, dispersant BYKP-105 0.01 g, 0.01 grams of benzene phenol, Deqian 488 is 0.01 grams, mixed under 55 ° C, stirred 60min The transparent uniform liquid is made; 0.5 grams of nano silica is added to the above-mentioned solution, and the mechanical stirring is 30 min to obtain a 3D printing elastic photosensitive resin.

[0036] The elastic photosensitive resin was placed in a DLP printer liquid slot, and the stretch pattern model was simulated in the computer. After the slice was completed, the underlying print was set to 40s, the underlying curing light was blue. The remaining layered cured light is white light, the exposure time is set to 8S, then by printing, the tensile sample is obtained for mechanical p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com